A supplier of semiconductor power management chips is using Ansys simulation tools to enhance design, development, and verification of its chip packages.

PITTSBURGH—Ansys reported that uPI Semiconductor Corp. is applying Ansys’s simulation software to speed up design for product packaging and double the thermal reliability of its power management products.

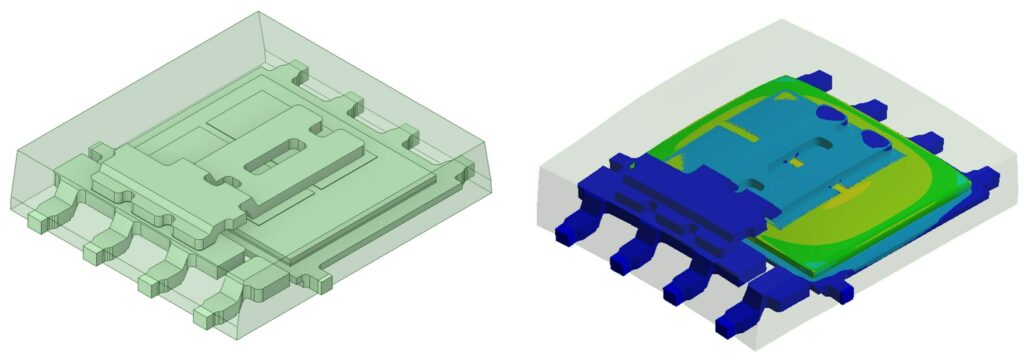

Ansys said in a release that uPI is using its software to analyze heat flow and thermomechanical stresses. By leveraging Ansys simulation, uPI can predict the electrical, mechanical, and thermal characteristics of its high-performance chip package designs quickly and with predictive accuracy, the company said.

This reportedly leads to improved product performance, streamlined design, and reduced risk of late-stage design changes for uPI, a supplier of semiconductor power management chips for high-performance computing (HPC) applications, communications hardware, battery management, industrial equipment, and consumer products.

Products that initially failed after 500 thermal test cycles were reportedly optimized with Ansys to endure more than 1,000 cycles. Ansys simulation tools also predict the electrical characteristics of packages across a range of signal frequencies, helping uPI engineers identify optimal design solutions and improve product performance, according to the release.

“Chip package design involves complex, multi-dimensional engineering that is nonlinear and can behave unexpectedly, even for small changes,” said John Lee, vice president and general manager of the electronics, semiconductor, and optics business unit at Ansys, in the release. “Ansys’s simulation tools provide end-to-end multi-physics analyses that enable teams to gain insight quickly into multiple areas of chip packaging with predictive accuracy. With Ansys, uPI is able to maximize their R&D and reliability testing processes to achieve high-quality products.”

An Ansys multi-physics model is used to simulate thermal stress variation. (Graphic: Ansys/PRNewswire)