Tebots’ UV sanitation units could be used to disinfect personal items such as cellphones, tablets, face masks, ID badges, baseball caps, sunglasses, keys, wallets, jewelry, credit cards, bills, and coins. (Image courtesy Tebots, Inc.)

Paradigm-shifting design-build solutions require finding a company that thrives on seemingly impossible industrial design and manufacturing challenges.

By Del Williams

HUNTLEY, Ill.—Industrial manufacturers understand the importance of efficient and streamlined processes to stay competitive in the market. Industrial design-build encompasses just that—a project delivery method where a design-build company takes on the responsibility of the designing and manufacturing or assembly phases of a project.

Collaborating with an experienced and versatile industrial design-build firm can lead to innovative approaches that decrease cycle times, lower costs, and simplify operations. For those who are seeking creative and efficient problem-solving, partnering with a firm that can provide paradigm-shifting solutions may be just the answer they’re looking for.

Tebots, Inc. is an industrial design-build firm with diverse experience in designing devices, products, automation, and manufacturing to find creative solutions to seemingly impossible challenges. The company specializes in industrial prototyping and production. They have extensive and diverse experience that allows them to be bold and propose uncommon results, often in the form of an invention.

The founder of the company, Robert Tegel, considers himself a “disruptive innovator” and thrives on coming up with solutions to challenges that are thought to be unachievable. The outcomes he creates are specifically designed to speed up cycle times, reduce costs, and eliminate unnecessary complexity.

Tebots prides itself on offering tailored solutions rather than cookie-cutter approaches. With a focus on innovative methods and original ideas, they strive to be the go-to source for those seeking transformative products. The only thing required of the customer is “a positive perspective to give me the go-ahead to do something different,” said Tegel.

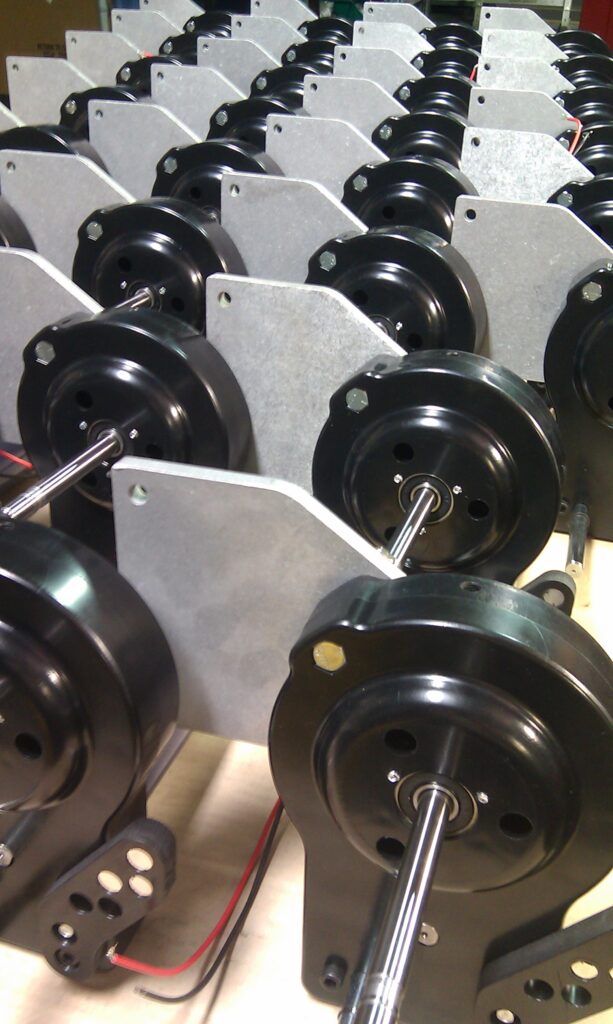

Tebots prides itself on offering tailored solutions rather than cookie-cutter approaches. (Image courtesy Tebots, Inc.)

A Swiss Army knife type of background

The strength of Tegel’s design-build experience lies in the diverse range of his specific background, resembling a “Swiss Army knife.” His career has been marked by maintaining, engineering, and inventing various types of equipment.

During his early years, he initially pursued a career as an auto mechanic but ultimately transitioned into diverse roles in the field. These included installing grain elevators, operating in foundries, improving high-speed sewing equipment, designing pumps for home coffee systems, manufacturing valve seals and inkjet cartridges, applying industrial testing and automation, and contributing to auto part assembly.

The common thread throughout Tegel’s career is in the wide range of equipment he has handled.

“One piece of equipment was the length of a city block, running very low RPMs and moving garbage and separating all kinds of different things, material processing different temperatures and heat, and then going into stuff that was running 400 cycles per minute,” Tegel said. “The next job I took was microprocessor-controlled high speed sewing equipment that was running 10,000 cycles per minute.”

Throughout his career, Tegel left a string of inventions in his wake. His first patent was issued in 1988. Within the textiles industry, he devised an innovative patented methodology for efficiently and repeatedly sewing T-shirt sleeves. His more than 30 issued patents include a pallet positioning system, a variety of dunnage systems and apparatus, and a discharge control valve.

Genesis of an industrial design-build operation

In 2005, Tegel decided to go into business himself. The company began as Tegel Design. However, one customer was so thrilled with the engineering that he asked the company to manufacture the product. In 2007, the industrial design-build firm, Tebots, was born of this request.

The company’s name, Tebots, is in many ways a precursor of the now popular term, “cobots.” A cobot, or collaborative robot, is a robot intended for direct human-robot interaction within a shared space, or where humans and robots are in proximity. An early Tebots logo depicted a robot engaging in a handshake with an individual, symbolizing the harmonious relationship between humans and machines—a philosophy infused in many of Tegel’s designs.

From those beginnings, Tebots began to accumulate internal production resources, such as machine centers, test and measurement equipment, and other production capabilities.

When parts are outsourced, the company works with supply chain vendors to receive high quality finished parts. Before delivering assembled sub-assemblies or complete machines, Tebots carries out an exhaustive quality control procedure using cutting-edge test and measurement systems.

Tegel now regards Tebots as a skunkworks-style operation—an innovative endeavor led by a select group of individuals operating outside the conventional research and development channels of the organization.

Tebots is an industrial design-build firm with diverse experience designing devices, products, automation, and manufacturing to find creative solutions to challenges. (Image courtesy Tebots, Inc.)

Ensuring efficiency and cost-effectiveness

In every design, Tebots consistently aims to optimize material usage and streamline assembly processes while upholding high quality standards. Meeting strict delivery schedules is an ongoing priority, with a dedicated focus on enhancing part efficiency, expediting production, and reducing costs. As such, Tebots’ designs are rooted in principles encompassing Design for Manufacturing (DFM) and Design for Assembly (DFA).

Design for Manufacturing (DFM) refers to the process of designing parts, components, or products with the objective of improving product quality while reducing costs through simplified, optimized, and refined product designs. Similarly, Design for Assembly (DFA) focuses on designing products that are easily assembled, aiming to minimize assembly time and associated costs by reducing the number of components involved.

To remain competitive against the Asian market, for example, Tegel has developed innovative strategies to streamline manufacturing processes and remove any unnecessary steps, ensuring efficiency and cost-effectiveness.

“There was constant competition with my customer to meet delivery costs in the Asian market, so I had to come up with extremely lean, net zero bill of materials,” said Tegel.

In one example, his customer was purchasing a machined structure to hold a machine up like a stand. The structures, bought from a supplier in China for $420, were welded together before being shipped to the United States.

Tebots produced the same part using patent-pending tubular connections that reportedly provide a strength and rigidity similar to that of a welded connection, for a third of the cost. The now patented methodology, known as the OmniStand, is currently being offered by Grundlage Solutions (https://grundlage.solutions/). According to Grundlage Solutions’ website, the OmniStand “can be used to support just about anything that can be attached to it.” It can also be disassembled easily if needed.

Before delivering assembled sub-assemblies or complete machines, an exhaustive quality control procedure is carried out utilizing cutting-edge test and measurement systems. (Image courtesy Tebots, Inc.)

An eye on future paradigm shifts

According to Tegel, the primary objective in design-build is to devise a solution that is efficient, cost-effective, and feasible to meet the immediate requirement. However, he also consistently keeps an eye on the potential for future iterations or models.

“When designing, it is crucial to consider the potential development of the product over time, with an eye on how we can move to a new paradigm or segue into new way of doing things,” said Tegel.

When the COVID-19 pandemic occurred, Tegel identified an opportunity that he felt would hold significant value in the future, beyond the crisis. Despite lacking dedicated customer funding for the project, he decided to invest his own efforts and expertise.

The result was a unique and patented ultraviolet (UV) disinfection system called the POZ. The device uses short-wavelength ultraviolet C (UV-C) light to inactivate pathogens, including viruses (such as SARS-CoV-2), bacteria, mold spores, and yeast.

Never one to shy away from collaboration when required, Tegel reached out to Turan Erdogan, a former research professor at the University of Rochester’s Institute of Optics.

“Collaboration is key when it comes to areas where you may not have expertise,” said Tegel.

Although there are already many UV light devices on the market, Tegel and his team had to overcome several inherent limitations in design. Many require direct contact and manipulation to operate the appliance, and there can be questions about the intensity and contact time of the applied UV light. If the item is treated in a static manner (for example, if it is placed in an enclosure without being rotated or moved), the UV-C light may not reach all the relevant surfaces.

“Simply adding a UV lamp to a product and expecting it to destroy pathogens does not mean it will be effective,” said Tegel. “UV light sources can vary in intensity and output, and there can be line-of-sight issues as well. You have to make sure the UV light is directed at the items from many angles with uniform intensity, and all this requires a high level of engineering.”

The patent-pending UV disinfection appliance resembles a small, portable charcoal grill. Tablet sized or smaller items are placed on a rotating platform and then move in a 360-degree arc through the chamber, where they are bombarded from all angles by UV-C light for approximately 10 seconds.

“Because the item is moving through the chamber, we can direct the UV-C in a way that ensures it will hit the targeted surface. By controlling the internal environment and the time within the chamber very precisely, we can kill more than 99.9 percent of the pathogens on the surfaces of the item,” said Tegel.

Tegel envisions the self-service disinfection stations being installed in front of entries/exits or bathrooms at public venues, retail stores, healthcare facilities, academic institutions, airport terminals, and nursing homes, to name a few. The units could be used to disinfect personal items such as cellphones, tablets, face masks, ID badges, baseball caps, sunglasses, keys, wallets, jewelry, credit cards, bills, and coins.

The company hopes to engage in discussions with several entities to license the technology. The initial design and several full prototypes have already been created.

At the time, the primary driver to develop this technology was COVID-19. However, Tegel said the intention was to create a device that addresses both existing and future health challenges as well.

“This isn’t just a COVID-related product,” said Tegel. “It is a product and an approach that could have a lasting impact on hygiene now and in the future, using a technology [UV-C] that has been around long before the pandemic.”

Del Williams is a technical writer based in Torrance, California.