The 4Di InSpec AT provides automated, non-contact measurement of surface features and defects on aircraft and aerospace components. (Image courtesy 4D Technology)

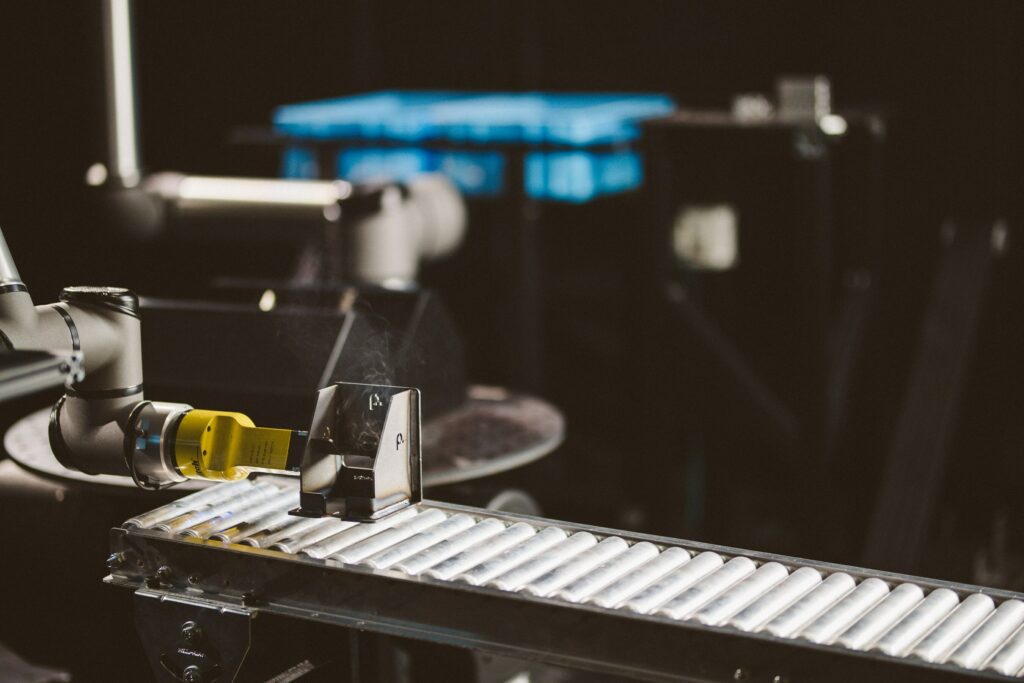

COLUMBUS, Ohio—A new robotic system from Path Robotics is capable of performing fit-up and welding of metal parts, according to a release from Path Robotics, a developer of autonomous welding robotic systems.

The Autonomous Fit-up robotic system, AF-1, leverages proprietary computer vision and AI to autonomously pick, fit-up, and weld small parts. It enables manufacturers to increase production throughput without the need for hiring fitters, welders, and programmers, the company said in the release.

According to Path Robotics, manufacturers simply load in raw components, hit go, and come back to a batch of welded parts. AF-1 cells run autonomously for hours with zero human intervention. As part of Path’s RaaS (Robots-as-a-Service) offering, Path provides manufacturers with 24/7 production assistance via its Mission Control command center, the company said.

“Today marks a significant milestone in the advancement of American manufacturing,” said Andy Lonsberry, co-founder and CEO of Path Robotics, in the release. “We are excited to publicly unveil a system we have been developing for years that we know will change the landscape of manufacturing for years to come.”

Hutchens Industries, Inc., a designer and manufacturer of spring suspensions and sliding subframes for the trailer industry, was one of the early partners for Path during the development of AF-1. “We see the AF-1 cells as a way to continue to grow our company and to alleviate our labor gaps currently and into the future,” said Ty Hutchens, executive vice president and chief operating officer at Hutchens Industries, in the release.

Path Robotics said it currently has a backlog of orders for the system extending into late 2023, and is continuing to actively sign innovative manufacturers to the platform.

The company said it offers American manufacturers the flexibility and resilience of intelligent robotics by creating robotic systems that leverage state-of-the-art artificial intelligence, machine learning, and computer vision systems. “Our mission is to transform the ability of local manufacturers to thrive,” the company said in the release.