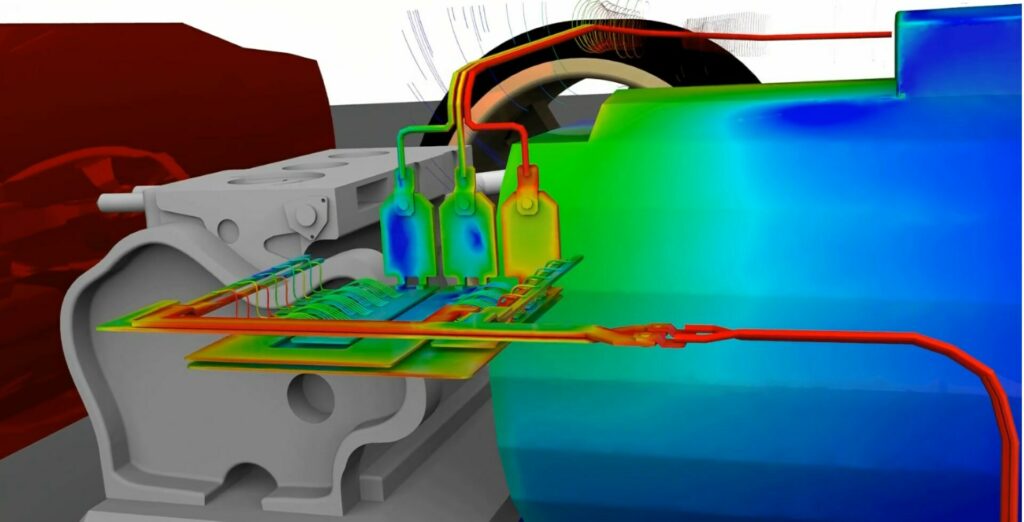

In Ansys 2023 R2, a full EV power electronics electrothermal workflow provides solutions from power IC, to package, to board with Ansys SIwave-CPA and Ansys Q3D Extractor (pictured). (Image courtesy Ansys)

Ansys’s latest release expands digital engineering capabilities with advanced solvers and large-scale computing in connected workflows, the developer says

PITTSBURGH—The latest software release from Ansys is reported to support electronic innovations, from 3D integrated circuits (3D-IC) to electric vehicles (EVs), via sophisticated numerics that integrate multiphysics solvers.

Ansys 2023 R2 enables distributed engineering teams, expanding their capabilities with powerful solvers and large-scale computing in connected workflows. It offers a simulation-driven design tool can help make digital engineering more accessible and immediate by performing live structural physics on 3D models, the company said in a release.

Ansys said the new release expands support for high-performance computing (HPC), graphics processing unit (GPU) acceleration, and cloud computing. It reportedly combines a unique range of enhanced numerics capabilities, performance improvements, and cross-disciplinary engineering tools to equip organizations with advanced physics solvers, scalable GPU-based computing, and seamless workflows.

“From semiconductor manufacturers to electric vehicle makers and autonomous aircraft developers, our latest software release empowers these organizations with scalable digital engineering workflows that are critical to digital transformation,” said Shane Emswiler, senior vice president of products at Ansys, in a statement. “Virtual design and development is at the forefront of transformational innovation within leading organizations across industries, and we are helping to make this a reality.”

Industries innovate, collaborate with digital engineering

Advanced electronics are critical to next-generation product designs like electric vehicles (EVs), vertical takeoff and landing aircraft, and life-saving medical devices. These products depend on new semiconductor and integrated circuit (IC) technologies, as well as advanced electronic capabilities. Innovations like high-density 3D-ICs enable product development teams to pack more features in a smaller space, but those compact form factors complicate thermal, electromagnetic (EM), and power challenges, according to Ansys.

Ansys said that major semiconductor foundries have certified Ansys software for their most advanced technology nodes. Its electrothermal tools “are essential to reliable 3D-IC design,” the company said in the release.

The latest updates to Ansys® RedHawk-SC™, a multiphysics sign-off solution for semiconductors, are said to significantly accelerate thermal analysis workflows. A complete EM simulation and modeling chain for IC design integrates the Ansys High Frequency Structure Simulator (HFSS), Ansys® Q3D Extractor® parasitic extraction analysis, and the Ansys® RaptorX™ EM solver, Ansys said.

In addition, Ansys EMC Plus (formerly Ansys EMA3D Cable) now offers a full electromagnetic compatibility (EMC) workflow. New integrated features in 2023 R2 enable engineers to efficiently meet high-tech challenges amid increasingly complex product requirements, the company said.

Specific industry sectors like healthcare, automotive, and aerospace are also said to benefit from Ansys digital engineering workflows in 2023 R2. A full EV power electronics electrothermal workflow provides solutions from power IC, to package, to board with Ansys SIwave-CPA for signal integrity, power integrity, and EMI analysis, and the Ansys Q3D Extractor parasitic extraction tool. Electric vehicle designers can also use simulation to visualize sound sonograms and model brand-defining acoustics with an integrated Ansys® Motion™ and Ansys Sound workflow, the company said.

According to Ansys, engineers in aerospace and defense, as well as automotive industries, can benefit from the new digital safety collaboration platform in Ansys medini analyze 2023 R2, which serves as a central safety project hub across an organization. A new Ansys Digital Safety Manager web app replaces the existing desktop client, enabling centralized planning, monitoring, and validation of medini safety and cybersecurity projects.

“As a systems supplier for passenger cars, commercial vehicles, and industrial technology, ZF Friedrichshafen AG places great emphasis on agility and innovation,” said Gunter Gabelein, safety assessor at ZF Friedrichshafen AG, in the release. “To support exciting developments like autonomous driving and electric mobility, our R&D process must be fast, cost-effective, and technically precise. More and more projects are taking advantage of synergies provided by medini analyze.

“In a medium-size project, more than 300 hours of effort can be saved by the one-tool solution and the interfaces to third-party tools for architectures,” Gabelein continued. “ZF is a strong advocate for model-based engineering, and medini analyze helps to reduce the complexity of analysis for embedded systems.”

Speeding simulation with large-scale computing

Ansys said 2023 R2 enables users to run large jobs and help overcome hardware capacity limitations with high-performance computing, both on-premises and in the cloud. Enhanced solver algorithms capitalize on GPUs to speed simulation. In Ansys 2023 R2, the Fluids product line enables additional industrial simulations to run natively on GPUs, substantially reducing solve time and total power consumption.

For example, 2023 R2 extends multi-GPU support to sliding mesh, compressible flows, and eddy dissipation model combustion simulations. According to Ansys, that means analysis of internal combustion engines (ICE), centrifugal pumps and fans, turbochargers and compressors, stirred tanks and reactors, and hydraulic machinery “can now be supercharged with the Ansys® Fluent® multi-GPU solver.

The Ansys® Discovery™ simulation-driven 3D design tool is reported to be even more predictively accurate with live structural physics, while “reducing GPU memory requirements for thin structures by up to 10X.” Subdivision geometry modeling in Discovery is said to provide a new way to create and edit complex parts, enabling users to see the results of “what-if” changes almost instantly for numerous popular computer-aided design (CAD) models, including topology optimization results. Discovery has grown from providing four features in 2019 to 50 in 2023 R2, including turbulence models, electromagnetics, and manufacturing constraints, the company said.