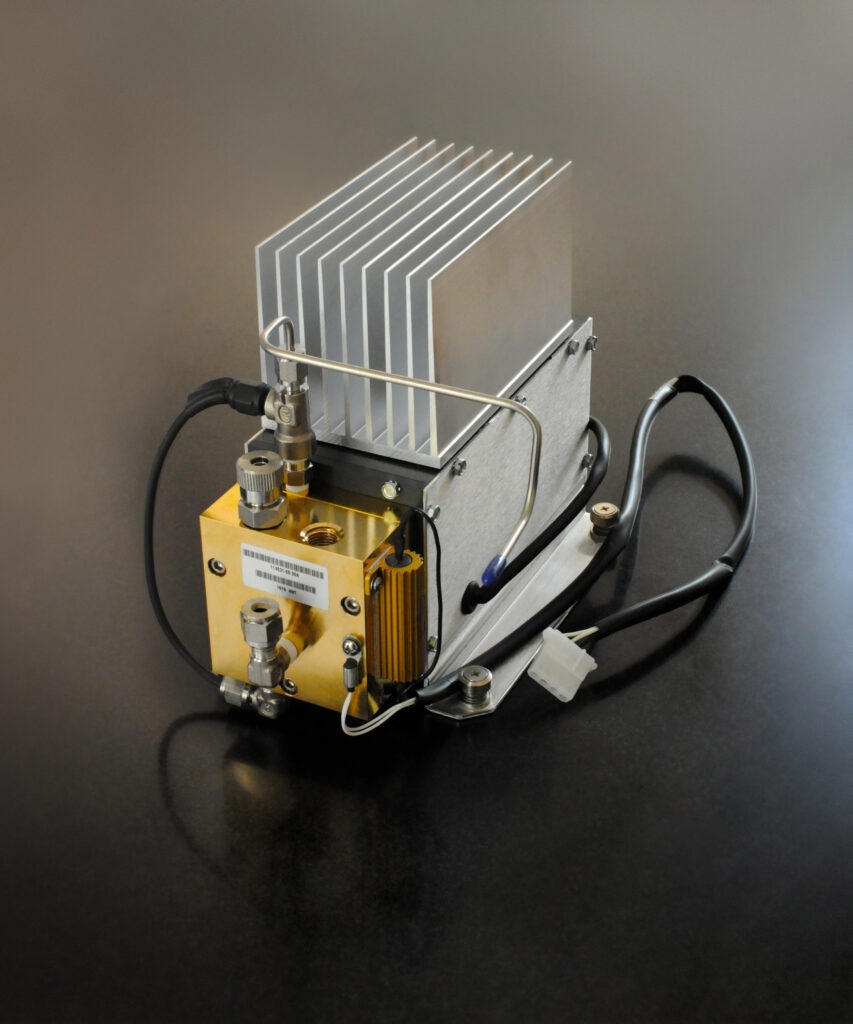

A photomultiplier tube assembly, assembled by Antron and ready for shipment. (Photo courtesy Antron Engineering & Machine)

Antron Engineering & Machine has earned a reputation as an expert provider of precision machined parts and product assemblies.

By Mark Langlois

BELLINGHAM, Mass.—A provider of precision CNC machining services with a process engineering approach, Antron Engineering & Machine takes pride in its ability to produce high-end products at the lowest possible cost.

Antron’s machining work ranges from one-offs and prototypes to production parts precisely machined with tolerances as tight as 0.0002 inch. At the other end of the size spectrum, the company produces warrantied, fully integrated, and fully tested electro-mechanical assemblies.

John Kauker and Anthony Denietolis founded Antron Engineering in 1985 when a plastic injection molding distributor needed a machine shop to finish its injection molded plastic parts. Antron drilled or tapped the holes and machined the parts. Today it operates an ISO-registered 35,000-square-foot facility with more than 70 employees in Bellingham.

The most common material machined by Antron is aluminum, but the company can machine almost anything that can be machined, as long as it isn’t a hazardous material. Materials such as steel, stainless steel, brass, machinable rubbers, machinable ceramics, and plastics are well within Antron’s capabilities.

In an interview with Design-2-Part, Kauker said that Antron sometimes machines parts that previously had been manufactured using a different process. It has converted castings into precision-machined parts, filling a need that has emerged as casting houses have become scarcer.

“Because of CNC machines today, some formerly cast pieces can now be precision machined,” he said. In the future, he expects that 3D printers, combined with milling machines, will offer enough precision and speed to handle some of these jobs. He said these types of hybrid machines are available today, but they need to improve in quality and speed.

From machined part to full-service electro-mechanical assembly

Precision machining was the company’s forte at its founding, and it remains its core business. With that bedrock firmly in place, Antron expanded into electro-mechanical assembly, which is now a steadily growing part of its business.

The company’s website states that Antron can handle “projects from a one-piece prototype machine component, all the way to a large quantity, fully integrated and fully tested electro-mechanical assembly.” Today, the company is regularly sought for its ability to complete difficult precision machining and product assembly projects.

“We’re a machine shop,” Kauker explained. “But a lot of customers today want to place one purchase order—they want a one-stop shop. The electro-mechanical assembly comes in when you have an assembly of sheet metal parts, machined parts, and parts unrelated to a machine shop, per se, like wiring harnesses, a PCB. Maybe five machine shops out of 100 will take on that responsibility, but we’re not afraid to do it.”

One reason why Antron’s electro-mechanical assembly is a growing part of its business is that customers are increasingly outsourcing that function as it becomes more difficult to find, hire, and train workers. However, many customers are not comfortable with the risks of contracting with 10 shops to make 10 parts, for example, because it creates 10 opportunities for one part to hold up the entire job.

Knowing that Antron’s quality management system is ISO 9001:2015 and AS9100D (aerospace) registered, and that its registration includes “assembly and test of precision components and assemblies,” many customers appreciate the fact that Antron takes full responsibility for the assembled product.

Some customers, preparing to make a 50-piece assembly, will farm out the work to numerous different machine shops because they’re worried that one of them might steal the job, despite having signed a non-disclosure agreement. Other customers, aware of Antron’s comprehensive capabilities in engineering, assembly, and testing, feel confident enough to give Antron the whole job. Kauker wants responsibility for the entire assembly so that Antron can get the job done right.

“More customers are leaning that way,” he said. “We’ll put the assembly together, test it, and warrantee it. We can test it down to 10 degrees Celsius, and up to 1800 degrees Fahrenheit. That’s what we do.”

An Antron team member performs a quality check for imperfections on a high-tolerance part. (Photo courtesy Antron Engineering & Machine)

Through its quality-controlled processes, Antron manufactures aerospace, medical, laboratory, and some military parts. Its quality management system is ISO 13485: 2016 registered for the contract manufacturing of precision medical components. Antron’s team holds a pre-production planning meeting and stays in touch with customers throughout the production process.

Kauker said customers often want to know where their parts are in the process, and if they’re done ahead of time, they want them now. “Ready to Ship” and “They’re ready if you want them early,” are messages that customers like to hear, he said. .

In addition to electro-mechanical assembly, Antron assembles and tests pharmaceutical and medical lab equipment, such as centrifuges for blood work and urine analysis. It also performs laser assemblies. Kauker said putting together a laser is similar to an electro-mechanical assembly, with a few key differences in components. A laser includes a diode, as well as a mirror and a laser source. “It has optics to direct the beam,” Kauker said.

A selection of finished parts precision machined by Antron Engineering & Machine. (Photo courtesy Antron Engineering & Machine)

Given the specialized nature of the components, Kauker wants testing the laser to be his job so that he knows it was put together as required. Antron has assembled lasers for use in eye surgery and tattoo removal, among other uses. In addition to assembling medical lasers, Antron manufactures tight tolerance aluminum tubes used in eye surgery. The narrow tubes guide instruments into the eye. One tube might help equalize the eye pressure, one might guide a laser, one might help clear debris from the surgery, and one might guide a light, he said.

Antron’s work for the aerospace industry includes machining tight tolerance parts for commercial aircraft. One example is a hydraulic pump part that can’t fail in flight. The company has also produced parts used in submarines, industrial equipment, and in battle in Desert Storm. He said these parts cannot fail when, for example, they’re sitting on an airfield in the Middle Eastern sun, and they can’t fail a couple of hours later when they’re cooled to below zero at 40,000 feet. They also can’t fail when flying through the humidity of the Amazon rain forest.

Coming through in a crisis, with no time to lose

During COVID, Antron was approached by government officials to create a swab-making machine at what Kauker called, “A 911 pace.”

“We want 10 machines, and we want them right now,” was the first approach. They gave Antron a firm deadline of three days to bid the job using somewhat hastily prepared bid documents. Once the bid was accepted, Antron had four weeks to assemble the first 10 machines.

Had Antron ever made swab machines? No. But its expertise was right for the job, Kauker said, because Antron was familiar with precisely machined metal parts and precisely machined plastic parts. It was also familiar with PCBs and wire harnesses, and it was somewhat familiar with air operating components.

“How hard is it to combine all that knowledge into making a new assembly?” asked Kauker. “They told me what a swab machine does. We just literally make the stick, and then the cotton balls from a strip from what looks like yarn. The machine cuts it up. It’s actually pretty impressive. It’s a relatively small machine too, probably about two-thirds the size of a desk.”

As Antron started to make the swab machines, Antron was ordered to remain open because it was an essential, critical part of the Defense Industrial Base. Military officials reporting to the Cabinet were directing its efforts, along with other firms across the country, to create machines that would manufacture millions of swabs during the COVID crisis. Due to the severity and circumstances surrounding the COVID crisis, the communications between Antron and the government were challenging.

Kauker said Antron received a call from a military official, a colonel, whom he described as a “super nice guy” who would not take ‘No’ for an answer. ‘I’ll see you on Monday,’ the Colonel told Kauker. “I told him Monday is Patriot’s Day,” Kauker replied, and the colonel said, “I’ll see you Monday.”

They toured the factory on Monday, and the colonel liked what he saw. He gave Antron three days to bid, saying, “I need a price on this equipment by Wednesday.” Kauker said he told the colonel, “Today’s a holiday. There’s no way I finish it by Wednesday.” The Colonel replied, “I’m telling you I need it by Wednesday.”

An Antron team member assembles a photomultiplier tube reaction chamber. (Photo courtesy Antron Engineering & Machine)

It didn’t matter that day one is a holiday. It didn’t matter that Antron needed to buy some of the electronic components—such as PCBs, wire harnesses, and air operating equipment—from vendors. It didn’t matter that much of the world was shut down. Kauker told the colonel that the bid would be high to protect Antron.

“I wouldn’t expect anything less. Otherwise I’d question your business ability,” the colonel said. He received the bid and told Antron that they had four weeks to give him 10 machines, Kauker said. Antron finished the assemblies in five weeks, and Kauker said he believed they could have completed them in four weeks if the documentation package had been easier to work with.

“Everybody was in such a hurry. They didn’t actually have a documentation package because they never needed swab machines in that kind of quantity so fast,” Kauker said.

In the end, the project was deemed a success, with Antron receiving praise for completing a difficult, multi-layered project in such a short amount of time. It led to a request for more work. “We want 24 more, and you know we need them now,” Antron’s team was told. Kauker said by then, Antron had worked out all the bugs. They finished the job on time.