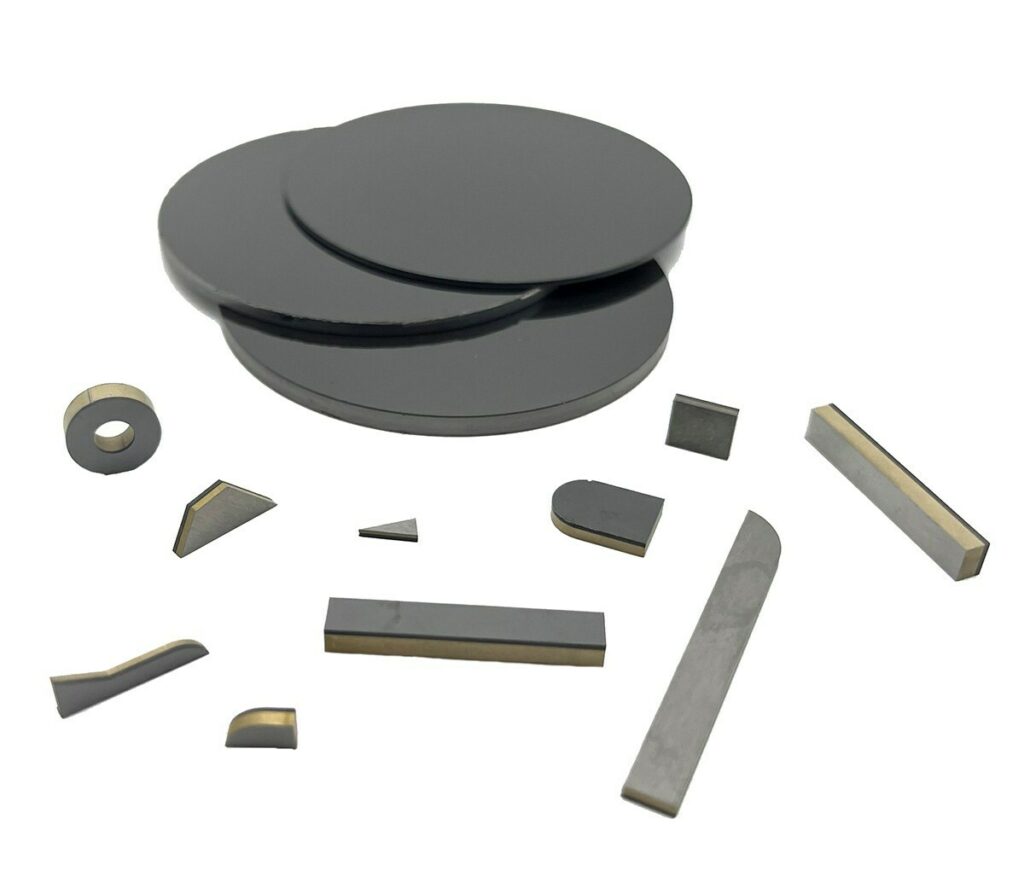

Hyperion Materials & Technologies specially designed its new P-Series PCD for tools used in machining nonferrous and nonmetallic workpieces for automotive, aerospace, electronics, and other precision applications that demand consistent performance and long-term cost savings. (Image courtesy Hyperion Materials & Technologies/PR Newswire)

The announcement follows the acquisition in June of Pennsylvania-based Dura-Metal Products, a manufacturer of wear-and corrosion-resistant precision tools and components.

WORTHINGTON, Ohio—Materials science company Hyperion Materials & Technologies recently introduced two new polycrystalline diamond (PCD) lines—the P-Series and U-Series—that expand the company’s offering to the toolmaking industry, the company said in a release.

Hyperion Materials & Technologies, an advanced materials company headquartered in Worthington, is a prominent manufacturer of hard and super-hard materials for demanding industrial applications. The company said it has more than 70 years of experience developing cemented carbide, diamond and cubic boron nitride technologies.

“Both product lines maximize value for performance and feature a higher level of quality consistency than is offered elsewhere due to Hyperion’s advanced quality control techniques that ensure the highest level of integrity for every blank shipped,” said Karl Tuffy, general manager of Hyperion’s Diamond business unit, in a release. “Hyperion is excited to offer these new product lines alongside its industry-leading premium COMPAX® PCD line.”

The P-Series PCD is specially designed for tools used in machining nonferrous and nonmetallic workpieces for automotive, aerospace, electronics, and other precision applications that demand consistent performance and long-term cost savings. It is reported to produce excellent results across a diverse range of workpieces, including aluminum, metal matrix composites, copper, carbon-fiber-reinforced polymers (CFRP), and other precision applications.

Hyperion’s U-Series PCD is explicitly designed for tools used in machining nonferrous and nonmetallic workpieces in woodworking, heavy machinery, and other utility applications. The product line is said to enable toolmakers to optimize costs without sacrificing reliability in machining applications where competitiveness and consistency are critical. Suggested applications include wood, medium-density fiberboard (MDF), melamine, laminates, particleboard, stone, concrete, and other difficult-to-machine applications, according to the release.

“The extension of Hyperion’s PCD portfolio offers more flexibility to our customers in choosing the right material for each job they pursue, all from one trusted and credible supplier,” said Hilary Interrante, Hyperion’s segment manager of Diamond Solids, in the release. “Our aim is to support our partners as the PCD tooling industry evolves.”

The P-Series and U-Series PCD lines are offered as discs with a 62mm usable area and as cut tips in either standard shapes or to customer drawings, the company said.

The announcement comes nearly five months after Hyperion reported in June that it acquired Dura-Metal Products Corporation, a Pennsylvania-based company that manufactures wear-and corrosion-resistant precision tools and components from cemented carbides, advanced technical ceramics, ferroalloys, and high-speed steels.

Dura-Metal employs more than 100 people at its 48,000-square-foot manufacturing facility about 30 miles southeast of Pittsburgh. The company has been making precision ultra-hard parts for more than 50 years, Hyperion said in a release.

“Dura-Metal has exceptional capabilities in machining and grinding of large components, electrical discharge machining (EDM), honing, lapping, and jig grinding that will expand and enhance our ability to serve customers in key markets that rely on custom precision wear parts, including aerospace, energy, battery manufacturing, electronics, medical, metalworking, and food and beverage,” said Ron Voigt, chief executive officer of Hyperion, in the release. “We’re excited to bring the team into the Hyperion family, and we’re already aligned in many important areas, including safety, quality, and building long-lasting relationships with our valued customers and business partners.”