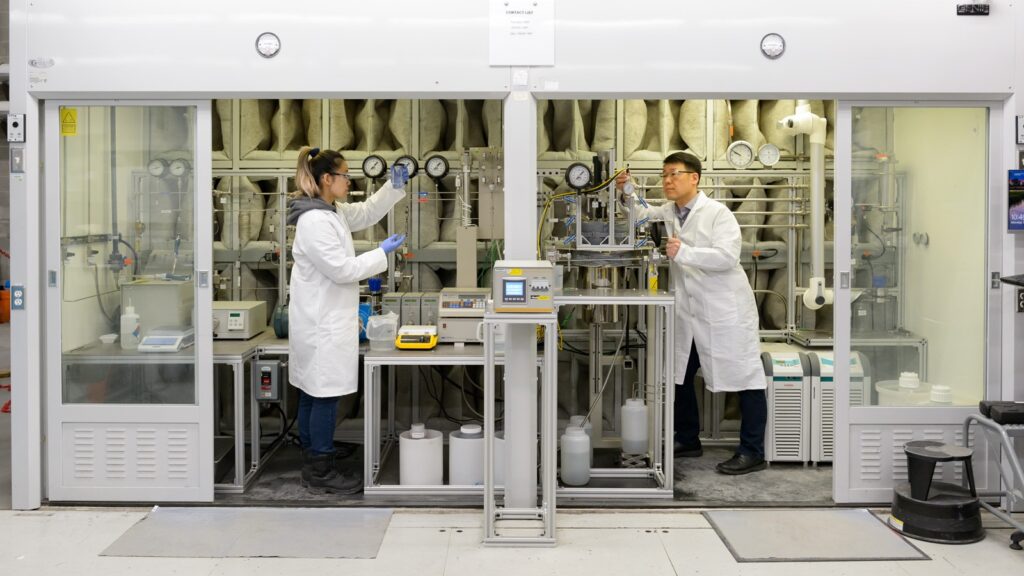

The Materials Engineering Research Facility is outfitted with state-of-the-art laboratory facilities, including a hydrothermal reactor, which allows researchers to develop and scale-up manufacturing processes for novel materials and chemicals. (Image by Argonne National Laboratory.)

By Jake Malooley

October 13, 2023

Argonne researchers draw on multidisciplinary expertise to develop cutting-edge technologies and techniques vital to the manufacturing sector.

Our ability to make things—from electronics to automobiles to food—and make them better depends on advances in science and technology. The ingenuity of researchers to develop innovative materials and novel production methods is especially important in today’s high-tech manufacturing world, which is being defined by extensive digitization.

In this transformational moment, the U.S. Department of Energy’s (DOE) Argonne National Laboratory is doing critical work toward the advancement of American manufacturing.

With a multidisciplinary approach drawing on expertise in everything from materials science to computational modeling and strong partnerships with industry, academia, and government, Argonne’s researchers are developing technologies and techniques vital to the manufacturing sector. This massive effort is bolstered by world-class laboratory facilities, high performance computing, artificial intelligence (AI), and machine learning capabilities.

Argonne has a unique ability to scale up production of new materials and chemicals—from a milligram made in the lab to the large amounts necessary for the commercial market. This enables the transition of research-based findings into applications that solve complex real-world problems. Some of the innovations that have emerged from the Lab include a novel cathode used in electric vehicle batteries, a reusable sponge that can soak up oil spills, a self-cleaning membrane utilized by water treatment facilities, and fungus-based alternatives to chicken and steak.

“At Argonne, because we are motivated by discovery, we can take more risks than profit-minded companies can afford to take in developing and scaling up the production of novel materials and chemicals,” said Chris Heckle, director of the Materials Manufacturing Innovation Center (MMIC), which the Lab established in 2021 to accelerate the scale-up of advanced materials and process technologies. To help bring new discoveries to market faster, Heckle cultivates partnerships that connect the Lab’s work with the needs of industry.

“Once we have a novel material, we want to get it out into the world to deliver societal impact. The question becomes how can we convene the right partners to get it through the proverbial valley of death?” Heckle said, referring to the gap between research and commercialization. “Manufacturing companies need to have a high level of confidence that the thing they’re investing in is going to yield.”

To help traverse the dreaded valley of death and demonstrate the technical and economic viability of promising new materials and technologies, Argonne turns to its Materials Engineering Research Facility (MERF). Launched in 2009, the MERF recently expanded to a 28,000-square-foot facility where some 50 scientists, engineers, and support staff develop innovative, scalable manufacturing processes. Here they can produce kilogram quantities of experimental materials and distribute them for industrial evaluation and prototyping, and to the R&D community for basic research.

During the last decade or so, Argonne has worked with more than 60 companies to drive innovative products to the market faster. Researchers leverage the Advanced Photon Source (APS), the Lab’s high-energy X-ray light source, for real-time insights into and analysis of new materials and chemicals. The supercomputing resources of the Argonne Leadership Computing Facility (ALCF), meanwhile, enable scientists to integrate simulation, AI, and machine learning into process development.

The APS and ALCF are DOE Office of Science user facilities at Argonne.

Over the years, the MERF has successfully scaled up dozens of materials, with a focus on battery materials for electric vehicles and chemical components for fuel cells. Research at the facility is funded, in part, by several offices within DOE’s Office of Energy Efficiency and Renewable Energy, including the Vehicle Technologies and the Hydrogen and Fuel Cell Technologies offices.

In the early 2000s, Argonne researchers made a major leap in lithium-ion batteries with the development of the nickel manganese cobalt blended cathode structure. That innovation can be found in many electric and hybrid vehicles currently on the road. But new advanced chemistries—which ideally are more efficient and can be domestically sourced—call for new and/or reformulated materials. That’s where the work done at the MERF is critical.

“The researchers in the discovery lab create a new material, investigate the basic properties, and say, ‘Bingo—This is something promising!’ The next step is the MERF developing the process to demonstrate to industry that the material can be made on a large scale without compromising performance, and that it will be less expensive, more efficient, and safe,” said Krzysztof Pupek, MERF group leader and a senior process R&D chemist. “Argonne is at the forefront of creating these new advanced energy materials and allowing for prototyping and industry validation. Most likely one of the materials we are working on today will one day be in your electric vehicle battery, cell phone battery, or other electronic device.”

Among the MERF’s successes was partnering with BASF, one of the world’s largest chemical companies, in scaling up production of Pentia, a cotton growth regulator.

“BASF invented the process on how to make the material, but they did so at a very small scale. It was a five-gallon bucket of material, and their target was millions of gallons,” recalled Gregory Krumdick, who designed and helped establish the MERF and now is the director of Argonne’s Applied Materials division, where he leads process development and scale-up, among other programs. “There were issues with BASF’s original process that would’ve prevented the large-scale production of the material. So, at Argonne we developed a scalable process—the way of making large-scale continuous batches of the material.”

Argonne served as an advisor to Nufarm when it acquired the Pentia technology from BASF in 2021, helping the agricultural chemical company learn the manufacturing process and get its plant up and running in Alsip, Illinois, not far from the Lab.

Argonne has also been at the vanguard of additive manufacturing. Also known as 3D printing, the method involves making a 3D object from a digital model through the mechanical addition of layer upon layer of material.

The Lab has helped advance, for instance, the 3D printing of steel and other metal alloys, which had long been a challenge for industry. During the printing process, temperatures change quickly, making the structure of the atoms within the material difficult for scientists to observe. But utilizing the high-energy X-rays at Argonne’s APS, researchers were able to examine the subtle, rapid phase changes of materials as the steel was being printed. That allowed them to monitor the formation of the material’s structure, determine its performance, and fine-tune the chemistry.

By opening up the ability to observe and optimize printing at the molecular level, Argonne has enabled the consistent creation of stronger, more durable, and more cost-effective components for industrial machinery, marine vessels, aircraft, medical devices, and so on. This pioneering work has set the stage for manufacturers to use 3D printing to reduce costs and increase flexibility as compared to traditional manufacturing methods.

Argonne’s work in additive manufacturing is also helping determine the continuing advancement of the nuclear industry. Specifically, 3D printing is playing a role in the design of the next generation of reactors. Because nuclear power emits no carbon dioxide, such research could be key to helping meet the world’s future clean energy needs.

“3D printing gives you a lot of flexibility in the design of a nuclear component. You can create complex geometries that previously could not be done, and that gives you a new opportunity to improve the efficiency of, say, a reactor’s heat exchanger or even the reactor’s core structure,” said Meimei Li, who manages Argonne’s nuclear materials group and is also the national technical director for the Advanced Methods for Manufacturing program within the DOE Office of Nuclear Energy.

“A nuclear reactor is an extreme environment involving high temperature, corrosive chemistries, and radiation. So, developing materials that can survive many decades in such extreme conditions is a very big challenge for material scientists,” Li said. “Additive manufacturing, which allows you to change a material’s microstructure in a way that cannot be achieved using conventional methods, opens a large space in the search for high-performance materials.”

Yet another remarkable aspect of Argonne’s contributions to manufacturing is its advanced computer modeling capabilities.

In the same way that the Lab’s scientists have used digital models driven by some of the world’s most powerful supercomputers to forecast everything from the impact of intervention methods on COVID-19 infection rates to the effects of climate change 50 years in the future, Argonne’s manufacturing-related models allow companies to simulate complex industrial technologies and processes. [They also enable them] to understand the behavior of materials at the molecular level, iterate new products, evaluate prototypes, and determine optimal design specifications.

One Argonne researcher, for instance, used ALCF supercomputers to run some 10,000 simulations of a combustion engine to determine which design would yield the cleanest, most fuel-efficient version. Such high-fidelity simulations are augmented with machine learning capabilities to accelerate the processing of high volumes of complex data, ultimately reducing design time from many months to just days, while lowering development costs.

Argonne’s modeling expertise extends to the development and evaluation of smart, sustainable, and other emerging manufacturing practices.

Sarang Supekar is a principal systems scientist and industrial technologies team lead at Argonne’s Center for Energy, Environmental, and Economic Systems Analysis. He and his team support DOE’s Advanced Materials & Manufacturing Technologies Office and Industrial Efficiency and Decarbonization Office through strategic technical analysis of manufacturing technologies and systems.

Supekar’s recent work has included developing a framework that allows companies to quantify and analyze the benefits of adopting smart manufacturing technologies. Those include “cyber-physical systems,” where computers monitor the manufacturing process and allow real-time improvements to product quality.

Officials cut the ribbon on the expanded Materials Engineering Research Facility in 2020. (Image by Argonne National Laboratory.)

In another project, his group analyzed the feasibility of recovering critical materials from hybrid electric vehicle batteries in the United States. That research dovetails with efforts at the DOE ReCell Center, located at Argonne, which is focused on advancing battery recycling and sustainable materials for energy storage, including reuse of end-of-life electric vehicle battery materials to support a circular economy.

“At Argonne, sustainability, decarbonization, and materials for a clean energy future are a big part of the mission,” Supekar said. “The work we’re doing is so critical because it’s extremely important to think from a systems perspective when trying to solve one problem so that we don’t create other problems.”

For instance, if recovering a battery material is as costly and requires many of the same toxic and energy-intensive chemicals as using virgin material, then Supekar would say more research needs to be done to eliminate or lower those barriers. “Being aware of trade-offs, and trying to preemptively control for them, is vital to the mission of sustainability,” he said.

As industries strive for greater efficiency, innovation, and viability in an increasingly digitized manufacturing landscape, Argonne’s dedication to cutting-edge research and real-world implementation is essential. The laboratory is also well positioned to help the United States blaze a trail of innovation toward the next frontier of manufacturing, in which machines and humans work together with greater efficiency and sustainability. Through its dogged advanced manufacturing research, the laboratory is ensuring a more prosperous and sustainable future for U.S. industry, the economy, and society as a whole.

Argonne National Laboratory and its Facilities

Argonne National Laboratory seeks solutions to pressing national problems in science and technology. The nation’s first national laboratory, Argonne conducts leading-edge basic and applied scientific research in virtually every scientific discipline. Argonne researchers work closely with researchers from hundreds of companies, universities, and federal, state, and municipal agencies to help them solve their specific problems, advance America’s scientific leadership and prepare the nation for a better future. More information is available at https://www.anl.gov/.

With employees from more than 60 nations, Argonne is managed by UChicago Argonne, LLC for the U.S. Department of Energy’s Office of Science. The U.S. Department of Energy’s Office of Science is the single largest supporter of basic research in the physical sciences in the United States and is working to address some of the most pressing challenges of our time. For more information, visit https:/energy.gov/science.

“At Argonne, because we are motivated by discovery, we can take more risks than profit-minded companies can afford to take in developing and scaling up the production of novel materials and chemicals.”

— Chris Heckle, director of the Materials Manufacturing Innovation Center at Argonne

The Argonne Leadership Computing Facility provides supercomputing capabilities to the scientific and engineering community to advance fundamental discovery and understanding in a broad range of disciplines. Supported by the U.S. Department of Energy’s (DOE’s) Office of Science, Advanced Scientific Computing Research (ASCR) program, the ALCF is one of two DOE Leadership Computing Facilities in the nation dedicated to open science.

The U. S. Department of Energy Office of Science’s Advanced Photon Source (APS) at Argonne National Laboratory is one of the world’s most productive X-ray light source facilities. The APS provides high-brightness X-ray beams to a diverse community of researchers in materials science, chemistry, condensed matter physics, the life and environmental sciences, and applied research. These X-rays are ideally suited for explorations of materials and biological structures; elemental distribution; chemical, magnetic, electronic states; and a wide range of technologically important engineering systems from batteries to fuel injector sprays, all of which are the foundations of our nation’s economic, technological, and physical well-being.

This research used resources of the Advanced Photon Source, a U.S. DOE Office of Science User Facility operated for the DOE Office of Science by Argonne National Laboratory under Contract No. DE-AC02-06CH11357.

Jake Malooley is a writer for Argonne National Laboratory’s Communications and Public Affairs Division.

This article was originally published by Argonne National Laboratory.

Source: https://www.anl.gov/article/a-revolution-in-the-making