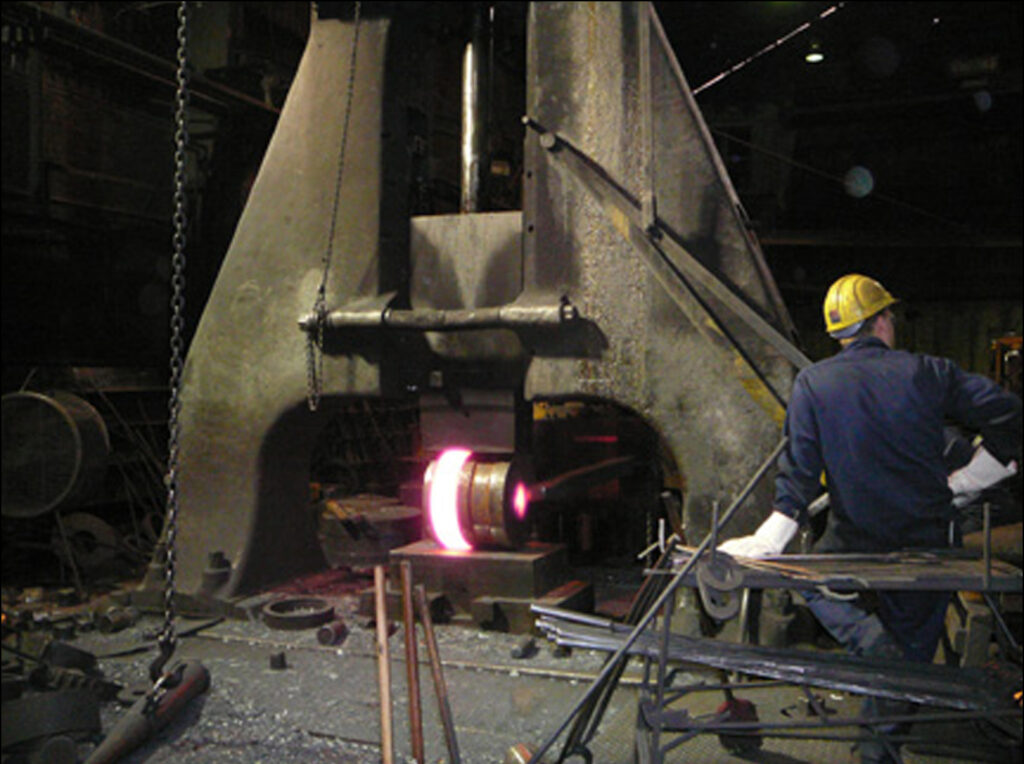

Specialty forgers All Metals & Forge Group can manufacture custom, high-quality, seamless rolled rings in a variety of materials and finishes, in as little as eight weeks. (Photo courtesy All Metals & Forge Group)

Specialty forgers can manufacture custom, high-quality, seamless rolled rings in a variety of materials and finishes in as little as eight weeks.

By Del Williams

A wide range of industries, such as aerospace, automotive, mining, oil and gas, machinery manufacturing, and power generation, rely on seamless rolled rings. These rings are critical components used for gears, turbines, bearings, clutches, couplings, drives, flanges, valves, machines, robotics, and other forged shapes.

Seamless rolled rings have a greater lifespan than other products due to their strength and durability, and are less prone to cracking or warping, making the option ideal for critical components requiring high tensile strength. Seamless rolled rings resist wear, fatigue, and stress, enabling better performance. Depending on the metal and alloy, the rings are also resistant to thermal and chemical damage, which further extends longevity while reducing the need for maintenance, repair, and replacement.

Obtaining large seamless rolled rings in a timely manner remains a significant challenge, however. Currently, it may take many months to receive the forged components after placing an order. This delay can have a severe impact on the production and maintenance schedules of industrial firms that depend on replacement parts.

Rings are typically provided with a rough surface finish, which necessitates the use of CNC machining to achieve the required level of smoothness. This poses a challenge for machine shops with a high workload, as allocating machine time for finishing inevitably leads to a decrease in production speed and an increase in costs, ultimately impacting the end-use cost or profitability.

Fortunately, manufacturers can rely on industry-leading forging specialists capable of producing large, custom, seamless rolled rings, and contoured seamless rolled rings with the required surface finish in under two months. One example, All Metals & Forge Group, an ISO 9001:2015 and AS9100D manufacturer of custom and standard open die forged parts and seamless rolled rings, can cost-effectively deliver these components with the required finish within eight to 10 weeks.

The range of forged products includes rings, discs, hubs, blocks, shafts (including step shafts or with flanges), sleeves, and gear blanks. It also includes cylinders, flats, hexes, rounds, plates, and custom shapes. Carbon steel, alloy steel, stainless steel, nickel, titanium, and aluminum are among the materials used for forging. These forgings meet rigorous industry specifications such as ASTM, AMS, AISI, ASME, Boeing, SAE, GE, DIN, ASME B 16.5, ASME B16.47, and API 6A.

Numerous industries can reap the advantages of an accelerated process for obtaining flawless rolled rings. This includes sectors like aerospace, aircraft, automotive, chemical, construction, defense, energy, engine and turbine, food processing, hydro, metalworking. Also included are mining, oil and gas, petroleum, power generation, pulp and paper, and shipbuilding.

The Benefits of Open Die Forging

One of the chief advantages of open die forging is the customization it offers in the seamless rolled ring manufacturing process. According to Lewis Weiss, president of All Metals & Forge Group, open die forging is ideal for providing large, custom parts.

“We can produce seamless rolled rings or contoured rolled rings up to 200 inches in outside diameter, and custom forgings up to 40 feet long or 80,000 pounds,” said Weiss. All Metals & Forge Group has been manufacturing and selling open die forgings and seamless rolled rings for more than 50 years.

While open die forging is typically associated with larger, simpler-shaped parts like bars or blanks, the process enables the creation of custom-designed metal components.

According to Weiss, open-die forging facilitates the production of seamless rolled rings to exact specifications, with optimized mechanical properties and structural integrity. He noted that the rings can be produced in a variety of alloys, sizes, and shapes specific to the requirements.

The forging of the rings is also cost-effective because the process reduces material waste and manufacturing costs. Because the rings are constructed from a single metal piece using a specialized ring rolling machine, there is no need for welding or assembly, saving time and labor.

The seamless rolled rings are also more structurally sound because they create a circular grain flow in the material, following the shape of the ring. This increases strength and integrity, creating a refined grain structure that can enhance the material’s fatigue resistance and overall performance. The result is a stronger, more durable final product compared to other methods of ring making, such as cutting from plate.

To optimize efficiency and reduce costs, rings can be produced as near-net-shaped forged parts with more refined surface finishes. (Photo courtesy All Metals & Forge Group)

Near Net Shape Parts with Finer Surface Finish

Typically, when seamless rolled rings are forged, they are often left in an unprocessed state with a rough surface measured at approximately 500 RMS. As a result, significant CNC machining time is required to achieve a smoother surface for the finished machined part. This represents a challenge for machine shops, as the allocation of machine time for finishing these rough parts directly affects production efficiency and delivery time.

To optimize efficiency and reduce costs, All Metals & Forge Group frequently provides near-net-shaped forged parts with more refined surface finishes.

“Typically, we provide a 250 RMS surface finish. We can even provide 125 RMS. We can also drill holes and do contour forgings as needed,” said Weiss.

“Some forge shops only offer a raw unmachined part. We produce a rough machine part, saving machine shop time and equipment wear and tear since we have already taken the first rough cuts off the ring or forged parts,” he added.

In addition, the company conducts ultrasonic testing at zero expense to the customer to guarantee the absence of internal cracks, pits, or voids. This instills the utmost confidence in the quality of the parts, according to Tim Grady, management consultant for All Metals & Forge Group.

“In many cases, All Metals & Forge Group can offer ultrasonically tested parts that are more affordable than raw forged rings,” said Grady.

Streamlining Delivery

In today’s market, the procurement of forged seamless rolled rings usually takes a considerable amount of time, from 20 weeks to as much as a year, as there are long lead times in receiving the necessary steel from mills.

“When replacement parts are required, a delay of a year or more is not acceptable,” said Grady. “Even 20-plus weeks is a serious issue.”

To expedite the process for customers, All Metals & Forge Group has established strategic partnerships within the industry, enabling the company to deliver many custom forgings in a time frame of eight to 10 weeks. Furthermore, to minimize any potential production downtime for machine shops, the company strives to provide accurate quotes within 48 hours.

A range of industries need these forgings, which are critical component parts for gears, turbines, bearings, clutches, couplings, drives, flanges, valves, machines, and robotics. (Photo courtesy All Metals & Forge Group)

Giving Back: A Rising Tide Lifts all Boats

In Weiss’s more than 50 years of industry experience with All Metals & Forge, he has learned a lot running a business that sells forged products globally to OEMs, major manufacturers, mid-size first- and second-tier suppliers, and small metalworking companies. Similarly, Grady brings more than 35 years of knowledge as a senior strategist and business advisor to companies of all sizes in more than 20 industry sectors.

Because of the increasing complexity of the manufacturing sector and market, the two decided to team up to share their expertise with manufacturers in all sectors to encourage discussion and promote overall industry success. The result is a weekly talk radio video podcast that All Metals & Forge Group sponsors, called Manufacturing Talk Radio, available on YouTube with any smartphone, computer, or tablet.

To keep those in the industry up to date, Weiss hosts the show along with Grady as co-host. The pair provides up-to-date news, technology developments, industry insights, and economic forecasts specifically tailored to manufacturing companies of all sizes worldwide.

On a weekly basis, the hosts thoroughly explore and enlighten their audience on significant subjects. Current discussions include topics such as reshoring in the United States, addressing the hiring obstacles within the industry, exploring financial avenues for small and mid-size manufacturers, effective B2B marketing strategies, optimizing website content for search engine visibility, and the latest advancements in artificial intelligence (AI) and machine learning.

Since Manufacturing Talk Radio’s launch in 2013, more than 800 episodes have been produced during the last 10 years. The show’s listeners gain key insights from a wide range of the industry’s most knowledgeable professionals. It is presently the most viewed manufacturing industry podcast, where 2,500 to 25,000 people click on each YouTube episode, with thousands more listening on Google Play, Apple Podcasts, Spotify, iHeartRadio, and more than 20 other podcast audio apps.

To help manufacturers of all sizes gain an additional edge in the market, All Metals & Forge Group also publishes a free monthly e-zine, called Manufacturing Outlook, which delivers the latest industry news, statistics, and reports to their inboxes each month. The digital e-zine alerts its nearly 10,000 monthly subscribers about consequential global, as well as regional, trends and developments that will affect their manufacturing businesses.

Positioning for the Future

The need to acquire seamless rolled rings will only increase in industries that require high-quality custom-forged components that can safely withstand extreme forces with minimal repair or replacement. In these cases, working with an expert forger who can expedite the process will convey a significant advantage.

For machine shops and manufacturers of all sizes, keeping abreast of the latest developments will be essential as well. In this effort, listening to industry experts like those from All Metals & Forge Group and their knowledgeable guests, and acting on the insights shared, will also be crucial to maintaining their competitiveness far into the future.

Del Williams is a technical writer based in Torrance, California.