By reducing friction, Industrial Hard Carbon’s protective thin-film coatings can help extend the lifespan of gears used in high-performance engines. (Photo courtesy Industrial Hard Carbon)

Industrial Hard Carbon’s protective coatings are reported to improve performance and durability of parts used in a range of critical machinery and equipment.

By Mark Shortt

The expertise of a small precision engineering firm in Denver, North Carolina has been a life-saver for individuals, small businesses, large manufacturers, and even world-champion racing teams.

Industrial Hard Carbon, LLC (IHC), is known for applying its protective thin-film coatings and surface finishes to parts that operate in a variety of critical, high-performance equipment. These innovative coatings are reported to significantly improve the performance and durability of equipment in sectors ranging from biomedical to defense, motorsport, aerospace, automotive, and industrial, among others.

“Our innovative protective coatings reduce wear and parasitic friction by providing a combination of hardness, lubricity, and flexibility to parts,” said Industrial Hard Carbon CEO Carrie DiMarzio, in an emailed response to a Design-2-Part survey. “Basically, we can contribute to any field where manufacturing applies and where parts are used—our services fit many problems and provide solutions that can improve the functional lifespan of parts to then reduce downtime.”

The properties of Industrial Hard Carbon’s thin film coatings can help make industrial manufacturers more efficient by increasing the longevity of their machinery. In the oil and gas sector, the coatings protect parts from salt-water corrosion and help them withstand the pressure increases of drilling over the long term. When applied to textile manufacturing machinery, the coatings can decrease physical and chemical damage to the machinery, ultimately protecting the manufactured products from shredding or damage, DiMarzio said.

Industrial Hard Carbon’s engineers are capable of designing parts for production, using thin film coatings to enhance product offerings, or solving problems for parts already in production. Ideally, they will enter the design phase before a part goes to manufacturing.

“This way, we can assess our coatings/films on parts before they enter full manufacturing and get placed into products,” DiMarzio said. “However, we can also provide solutions to problems with parts that have been manufactured. If a customer has a bottleneck or a failure point and needs to solve a problem, we can jump in and offer potential solutions. Industrial Hard Carbon can provide engineered solutions to any project, regardless of size or scale.”

Responding to a D2P survey on Industrial Hard Carbon’s capabilities and services, DiMarzio shed further light on IHC’s strengths. Following are her responses, edited for length and clarity.

Design-2-Part: What design, engineering, or manufacturing services does your company provide in support of the industries you serve?

Carrie DiMarzio: We can provide turnkey solutions to manufacturers—such as surface-finishing and coating solutions for individual parts. Overall, we can provide each customer and each part with the best coating available.

If we enter discussions with customers after the part is manufactured, and they see some type of problem, such as untimely wear or high friction, we can start our analyses and suggest optimized solutions. Our exploratory/evaluation processes involve a great deal of support services—including surface modification, metrology, and materials science—to make the correct recommendations about what might work for a customer. This process involves a tremendous amount of R&D, set-up, and failure analysis, which will provide the best solution when coupled with our in-house testing.

We see the testing and validation process as a goldmine of information for our customers. These processes also allow us to find flaws in the manufacturing process, opportunities to streamline, and perspectives that can change how our customers do business—working directly with machine shops and engineers to collaborate and produce a precision product that meets the highest quality standards.

Industrial Hard Carbon specializes in surface solutions/surface alterations by applying our thin film coatings. In terms of design and engineering, we can provide turnkey solutions. While we do not do in-house manufacturing, we work closely with parts manufacturers. In this case, Industrial Hard Carbon is the driving force. We will lead the project from start to finish and deliver a final product with an optimal coating. We only work with high-quality precision fabricators who serve exacting requirements for their specific field.

D2P: What types of coatings does Industrial Hard Carbon apply to parts?

CD: The main products from Industrial Hard Carbon are coatings applied to an already finished part. While this may not be obvious to many, coatings are a vital component of any part. Ideally, discussions of coatings should form part of the initial design phase for most parts/products.

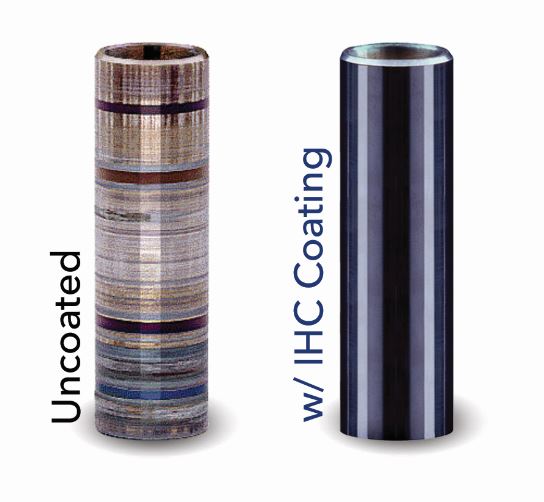

The photo shows the difference in two wristpins—one uncoated and the other with an Industrial Hard Carbon coating—after 600 miles of performance in a NASCAR® engine. (Photo courtesy Industrial Hard Carbon)

While any company may have a great part, the choice of an optimal coating can significantly improve the function and lifespan of these parts, making a “good” part much better. We employ a wide variety of coatings, which have different uses. This includes friction and wear reduction or temperature and corrosion resistance. The benefit of the coating applies to all of the previously discussed sectors.

Many types of coating exist—thick film, thin film, and spray-on coatings, for example. Industrial Hard Carbon provides thin film coatings of 1 to 10 microns (µm) that do not alter the final dimensions or have a minimal dimensional impact on the part. Examples of part development that we have been involved with include hydroentanglement strips in textile manufacture and a drive-shaft for a chemical pump. The shaft is in an aperture, and the shaft and the coating in the aperture represent the only seal within the pump.

We have been involved significantly in coating parts for motorsports; however, we have also been involved in the development of printing press parts for soda cans, designed so that the ink does not degrade the drive-shaft as they roll by, and in the development of molds for plastic extrusion, which is a vast industry. Again, Industrial Hard Carbon’s primary focus is providing coating solutions to our customers. We consult manufacturers regarding coatings, surface finishes, and the materials used.

Coming up with new part designs is essential to us here at Industrial Hard Carbon and is a huge help for most customers. We also undertake in-house testing and analysis (e.g., tribology) for various customers; this data represents a considerable resource that helps us to [assist] different manufacturers.

D2P: As a supplier/partner to OEMs and product manufacturers, what is your company’s biggest strength? Why do customers choose your services?

CD: Our biggest strength would almost certainly be delivering quality services with a quick turnaround time. Within the coating industry, you hear nightmare stories of customers getting promises from companies and then not getting their parts turnaround in time. Mistakes, miscommunication, or over-promising at this step can therefore lead to delays in projects. Industrial Hard Carbon always aims for a two-to-three-week turnaround, with a significant focus on delivering by two weeks where possible. This compares with turnaround times of well over a month with other companies in the same area.

In most industries, we are the last ones to touch the part—after manufacturing and quality control. Therefore, we need to work to the best of our abilities to turn around these parts quickly and get them to the customers and then into the machinery/application. The high quality and quality standards of our work and our focus on delivery times make us who we are as a company. That is why customers keep coming back to us for repeat jobs, engineering solutions, and anything they may need.

Our aims regarding quality apply to incoming and outgoing products. We put a lot of emphasis on the inspection of parts. We inspect everything when an order arrives on-site [to avoid the possibility of coating damaged goods].

When we receive a part from a customer, we do a full 100 percent inspection of the parts and then communicate our findings. In this way, we can highlight any initial problems and report any improvements that could be made before we move forward to the coating process. This ensures that we deliver the best possible service, and that the customer gets the best possible result. We partner with the customer from the beginning till the end. Therefore, it is not just a coating job for us here at Industrial Hard Carbon. Every part or customer, large or small, gets the same level of attention.

This approach—that attention to detail regarding quality, rapid turnaround times, and excellent customer service—goes a long way with our customers. When customers come to us with a problem, we aim to get back to them that day. That is of enormous importance to our customers who keep coming back to use our services. Keeping our customers out of trouble keeps us out of trouble. High-level communication between Industrial Hard Carbon and the customer helps them, helps us, and helps us to help them. Our mission is to exceed our customers’ expectations for quality, delivery, and service. Furthermore, we are ISO9001 certified; it serves us, and we take it seriously.

D2P: In what ways do the company’s personnel apply advanced skills or expertise in providing manufacturing services for your customers?

CD: Industrial Hard Carbon employs experts in the field of coatings. Alongside the expertise of our staff, we possess our own coating equipment that we manufacture ourselves, which further adds more skills and expertise.

We have significant multilevel know-how, thanks to our years of experience in applying and developing new coatings. We pride ourselves as the experts in the industry—our team can provide multiple coating and manufacturing solutions. A large part of the strength of our team comes from cross-training. Anyone who touches a part has been trained in multiple tasks, meaning that all staff can provide backup to whoever requires it for each specific problem. This level of help and reinforcement binds the team together and makes the passage of a part through Industrial Hard Carbon a rapid and effective repair.

D2P: Depending on the process used, what are some examples of tolerances or other quantifiable results that your company can achieve with your processes?

CD: The coating application process is fully automated, and each coating has its specific assigned “recipe.” Therefore, we can hold all parameters constant during a highly repeatable process. Once we go through the initial stage of developing a solution for a particular application or problem, we can repeatedly hold a customer-specified tolerance of around 0.1 to 0.5 micrometers for coating thickness.

Of course, we have the equipment and the skills to measure precisely and share those data to meet our customers’ wishes. We also supply certificates of compliance (COCs) to predetermined technical specifications for any part that leaves Industrial Hard Carbon.

Besides the thickness tolerance, adhesion levels are of the utmost importance to customers regarding coatings; these are also assessed before a part leaves the building. Poor coating adhesion can prompt premature wear or catastrophic failure; therefore, we employ methods that ensure that every coating batch possesses optimum adhesion as part of our quality control system.

Whatever we measure—the hardness of the coating, thickness of the coating, adhesion of the coating to the part—can be shared with the customer. Surface finish parameters measured using our metrology equipment also represent vital factors. All coating involves pre- and post-process, so it is not just a coat-and-dash situation. These parameters can be vital for the final use of the part, so we must show the customer that our processes keep the numbers in their pre-specified ranges.

Of note, we also measure a range of other specifications—such as indentation hardness and elastic modulus (DIN EN ISO 14577-1 and ASTM E 2546, both on the micro-/nano-scale)—to see that these values for any parts meet our internal specifications. Checking these and related parameters against our baselines can be very important while vetting a process for an application [as we develop] a new solution for a problem. In this sense, we are continually improving and educating ourselves, allowing us to improve and provide better service to the customer.

D2P: What additional capabilities or services do you offer that would be of interest to a design engineer, manufacturing engineer, or purchaser?

CD: Industrial Hard Carbon can take surface measurements and perform tribological measurements/testing in-house. With our in-house universal tribometer, we can obtain valuable data by designing experiments replicating the application environment as closely as possible. We can characterize friction, wear, adhesion, fatigue, and mechanical surface properties. These data are instrumental in developing tailored solutions for the most demanding applications. The enormous amounts of detail that we get from these measurements help to calculate wear rates and to understand the ability of the part, combined with the coating, to withstand varying loads.

All the measurements taken and shared with our customers adhere to ISO or ACM standards; therefore, these values are based on cross-industry standards. As mentioned before, we do a lot of consulting during the design stages for parts. Furthermore, we can carry out surface engineering, surface alterations by micro-polishing, in-house REM surface finishing, bearing coating services, and dry film lubricant services in addition to the coating services.

D2P: Can you tell us about any awards or certifications that your company has recently earned?

Industrial Hard Carbon is ISO 9001 certified, a prestigious certificate to have for any company. This certification goes a long way with manufacturers by showing that we abide by specific quality standards. Also of note, our engineers and their skills contributed to receiving a U.S. Department of Energy award for technology transfer. We received multiple awards through our collaborations with BioMedInnovations, an innovative health tech company developing a groundbreaking new organ and tissue perfusion technology. These successes showcase our capabilities when it comes to engineering, manufacturing, and technology transfer.

Furthermore, we have also cooperated with other leading research institutes in the United States, including the Lawrence Livermore National Laboratory (California). These collaborations facilitated the development of the SuppleVent® emergency-use ventilator in response to the COVID-19 pandemic. They involved the receipt of Federal Laboratory Consortium certificates for “Technology Transfer,” “Public Private Partnership,” and “COVID-19 Response.”

D2P: Could you describe, without disclosing proprietary information, an application that illustrates your firm’s ability to solve a technical challenge? What were the application/performance requirements? How did the company apply its services to meet these requirements?

CD: A recent job in which we perfectly designed a new film to solve a particular sealing application represents a great example of the ability of Industrial Hard Carbon to solve a technical challenge.

Among many notable successes, this most recent challenge that we overcame encompasses many areas where we demonstrate our expertise—from communicating with the customer and understanding the problem they are facing.

In this case, the customer saw accelerated wear in a part that had to withstand a demanding high-temperature environment. We were asked to come into the picture and provide a solution to this wear/sealing problem. We first sought to understand the part in detail and explore the reasons behind the failure; this involved a great deal of R&D work. By evaluating multiple and precise parameters for the part, surface finish, and coating (and how these different components affected each other), we could begin to understand the situation and the associated limits.

Basically, we analyzed the tribosystem as a whole to understand why the part had begun to fail. From this “failure analysis,” we came up with a new coating solution in a relatively rapid timeframe through a tremendous amount of in-house testing and parameter collection and comparisons against the baseline that we believed was going to perform well.

Of general importance, testing represents a costly and time-consuming process for everyone involved. We use our in-house measurement capabilities to be a step ahead of the game and not just “throw spaghetti at the wall and see what sticks.” We want to ensure the pasta is well cooked before serving it to the customer! Our in-house testing capabilities and expertise help to ensure that our work is moving in the right direction and, therefore, we are saving time and money in the testing stages, which is of great importance to us and, therefore, the customer.

The subsequent endurance testing conducted by the customer to date has been highly successful. The bottom line is that we not only developed the process/new coating, but we conducted as much in-house validation as possible with our metrology systems before the customer received and tested the part in their machine and got robust results. The newly designed coating withstood an application temperature of around 800 degrees Celsius and significantly reduced both the wear and the associated oxidation that was taking place. We were able to provide our services—our metrology system, our R&D background, and our know-how of coating equipment and processes—to fix each of the parameters efficiently and provide a robust, effective solution to this very tricky problem.

We had to design the tooling internally to solve the problem mentioned above by meeting the customer’s requirements. However, importantly, we designed the whole “experiment” that helped rapidly move through the process of providing a solution to the customer. We also undertook thin film engineering, such as what materials/constituents were used and how smooth the surface had to be. Importantly, we wove together two processes that generally are far from compatible for simultaneous use.

We came up with a process that was not intuitively obvious; we do a lot of that when it comes to getting a coating suited to the part! This strategy took multiple iterations during the engineering process, during which time we gained more knowledge on what tweaks would improve what parameters. This takes an entire team of highly skilled and motivated staff working together toward a common goal.