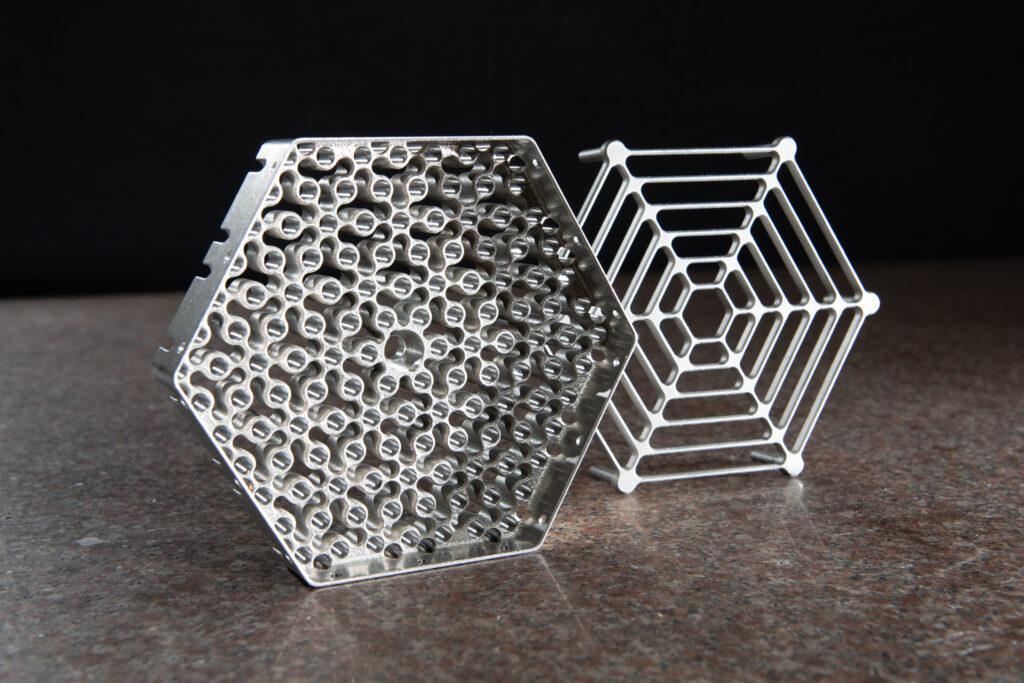

A fuel assembly component produced through additive manufacturing. (Photo: Business Wire)

Additive manufacturing reduces production costs and lead time while achieving the highest industry safety standards, the company said.

CRANBERRY TOWNSHIP, Pa.—Westinghouse Electric Company reported that it manufactured its 1,000th fuel flow plate using additive manufacturing (AM). The achievement represents “the first ever safety-related AM components to enter serial production,” the company said in a release.

The AM flow plates are installed in VVER-440 fuel assemblies, enabling a redesign of the bottom part of the assemblies that is said to enable more robust performance.

“This achievement showcases the development of additive manufacturing from prototyping to full-scale production, generating tangible value for our customers,” said Westinghouse Chief Technology Officer and Executive Vice President, R&D and Innovation, Lou Martínez Sancho, in the release. “This marks another Westinghouse pioneering achievement in AM Technology, holding the commitment to strengthen safety, efficiency, sustainability and energy security.”

According to Westinghouse, the milestone is a continuation of the company’s leadership in deploying additive manufacturing in the nuclear industry to achieve cost and lead-time reductions and enable cutting-edge solutions for energy generation. In 2015, the company conducted what it described as “the first ever material irradiation study of AM nuclear components.” In 2020, the company is said to have installed “the first ever safety-related AM component, a Thimble Plugging Device, into an operating commercial reactor.”

Westinghouse said it supplied the world’s first commercial pressurized water reactor in 1957. The company’s technology is said to be the basis for nearly one-half of the world’s operating nuclear plants.