AeroVironment is pioneering a new class of autonomous systems built for GPS-denied, high-threat environments.

AeroVironment recently launched the one-way attack UAS Red Dragon, “bringing the future of autonomous precision strike capabilities to the battlefield today,” the company said. (Photo courtesy AV)

ARLINGTON, Va.—A fully autonomous capable, software-defined unmanned aircraft system (UAS) recently launched by AeroVironment, Inc. (AV) is designed for one-way attack missions in high-threat, GPS-denied, and communications-degraded environments.

Known as Red Dragon™, the unmanned aircraft system was developed as part of AV’s expanding portfolio of tactical autonomy. It is built on AV’s AVACORE™ shared software architecture, enabling rapid development, scalable manufacturing, and modular mission integration, AV stated in a release.

AeroVironment’s SPOTR-Edge™ perception system enables detection and classification of targets to aid the operator in making decisions with confidence via AV’s proprietary DDIL radio system.

Red Dragon is reported to deliver a combination of autonomy, electronic warfare resilience, and tactical flexibility previously unavailable in its class. It is designed to penetrate contested airspace and operate effectively in denied, disrupted, intermittent, and low-bandwidth (DDIL) environments.

“The system is capable of autonomous execution of mission objectives without reliance on continuous operator input or satellite navigation,” the release stated.

Designed for manufacturing at scale, Red Dragon is said to enable mass production, rapid deployment, and simplified logistics to meet operational demands. It is optimized for cross-domain use—across air, land, and maritime—and is designed so small teams can be trained quickly and effectively, the company said in the release.

“Red Dragon represents a significant step forward in autonomous lethality,” said Jeff Rodrian, Executive Vice President, MacCready Works.

“By combining advanced autonomy, GNSS-independent navigation, and mass producibility, Red Dragon delivers a mission-ready system designed for today’s contested battlespace,” said Jeff Rodrian, executive vice president at MacCready Works. “It is the first of a new generation of autonomous systems built for scale, speed, and operational relevance.”

Red Dragon is the first in a rapidly growing family of platforms under development at AV with a common software and hardware architecture for mission-specific variants. Each shares a common software and autonomy architecture designed to support rapid evolution across domains and use cases. “This enables evolutions at the speed of software and warfare,” the release stated.

“At AV, our mission is to change the way wars are fought—by putting the safety, survivability, and operational advantage of our warfighters first,” said Wahid Nawabi, president and CEO of AV. “Red Dragon reflects the kind of breakthrough capability that ensures U.S. and allied forces stay ahead in an increasingly complex threat environment. It’s not just about autonomy—it’s about delivering trusted, mission-defining technologies that protect lives and reshape the future of defense.”

GE Aerospace Awarded Subcontract for Next Phase of Future Long Range Assault Aircraft

The Digital Backbone incorporates Time-Sensitive Networking to provide a reliable, high speed, data “highway” to meet current and future needs for moving data through the aircraft. (Photo courtesy GE Aerospace)

A time sensitive, networking-based digital backbone enables the U.S. Army’s high-speed data infrastructure for the aircraft.

CINCINNATI—GE Aerospace was recently awarded a subcontract as part of a team led by Bell Textron Inc., a Textron Inc. company, to design, develop, and deliver avionics systems for the United States Army’s Future Long Range Assault Aircraft (FLRAA) program.

The award follows Bell’s announcement of the U.S. Army’s approval of Milestone B, marking the next phase of engineering and manufacturing development (EMD), according to a release from GE Aerospace.

“The maturity of the digital backbone for the U.S. Army’s Future Long Range Assault Aircraft was critical to passing Milestone B and entering the engineering and manufacturing development phase of the program,” said Matt Burns, general manager of Avionics Systems for GE Aerospace, in a statement.

“Entering this next phase enables us to continue advancing the digital backbone for the U.S. Army’s future vertical lift programs,” said Tanika Watson, general manager, Future Vertical Lift for GE Aerospace, in a statement. “The Digital Backbone provides the framework to make aircraft system modifications and realize the benefits of Modular Open Systems Approach (MOSA) designs from the outset of Future Vertical Lift programs.”

The Digital Backbone will allow customers to make changes to the weapon system without going to the systems integrator, which optimizes the cost and speed of change. It incorporates Time-Sensitive Networking to provide a reliable, high speed, data “highway” to meet current and future needs for moving data through the aircraft.

In addition to the Digital Backbone announced in 2023, GE Aerospace also supplies the Health Awareness System for FLRAA. Building on decades of commercial and military operation, GE Aerospace’s Health Awareness System has reportedly saved operators “millions of dollars and increased mission readiness with predictive maintenance,” according to GE Aerospace.

GE Aerospace is a global aerospace propulsion, services, and systems company with an installed base of approximately 45,000 commercial and 25,000 military aircraft engines.

This material is based upon work supported by the Army Contracting Command-Redstone Arsenal under Contract No. W58RGZ-23-C-0001.

GE Aerospace Secures $5 Billion U.S. Air Force Contract for F110 Engines

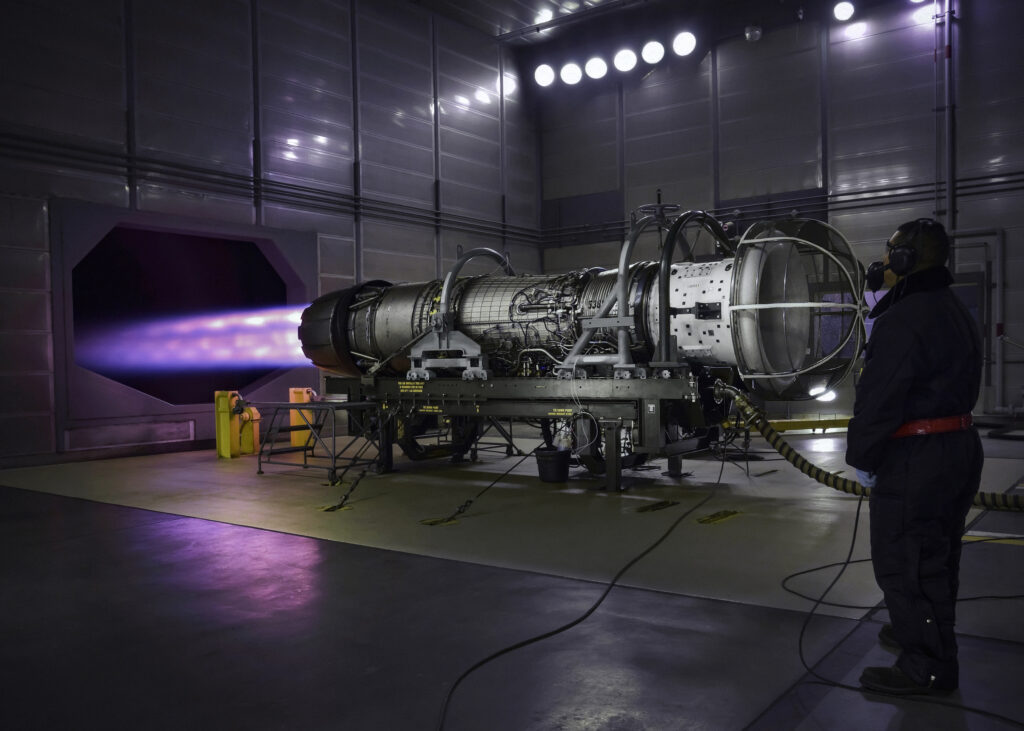

GE Aerospace recently secured a $5 billion U.S. Air Force Contract for F110 Engines (Image courtesy GE Aerospace)

CINCINNATI—GE Aerospace recently announced an Indefinite Delivery/Indefinite Quantity (IDIQ) contract from the U.S. Air Force valued up to $5 billion. Thecontract supports Foreign Military Sales (FMS) for F110-GE-129 engines, which power F-15 and F-16 aircraft operated by allied nations worldwide, according to a company release.

The GE Aerospace F110 engine is reported to have more than 11 million flight hours under its wing, the most thrust in its class, and recently celebrated a milestone of 40 years of continuous production and improvement. Through this latest agreement, GE Aerospace reaffirms its commitment to supporting U.S. Air Force partnerships and enabling operational readiness for F-15 and F-16 platforms globally, the company said in the release.

“We are honored to reach this agreement with the U.S. Air Force, ensuring the F110-GE-129 remains the engine of choice for the world’s F-15 and F-16 fleets,” said Amy Gowder, president and CEO, Defense & Systems at GE Aerospace. “This contract underscores the enduring trust in the F110’s performance, reliability, and value for our customers and their critical missions.”

According to GE Aerospace, the F110 engine family has a proven track record of providing superior thrust and operational efficiency for military customers. As part of this latest contract, GE Aerospace will collaborate closely with the U.S. Air Force to deliver engines, spares, and associated services that meet the evolving needs of allied operators, the company said.

QinetiQ US Selected by Integris Composites to Support U.S. Army’s Future Long Range Assault Aircraft

A Bell V-280 Valor tiltrotor, vertical takeoff and landing (VTOL) aircraft. (Photo courtesy Bell Helicopter)

The company will provide systems engineering and integration expertise using its protective, lightweight armor.

MCLEAN, Va.—QinetiQ US, a large global provider of add-on aircraft armor, reported in May that it received a contract from Integris Composites to support the U.S. Army’s Future Long Range Assault Aircraft (FLRAA) program. Under the contract, QinetiQ US will provide systems engineering and integration expertise using its LAST Armor® Integration, the company said in a release.

LAST Armor is a protective, lightweight armor that provides high-performance ballistic protection for fixed wing transport and rotary wing platforms. The armor is used by the U.S. Military, foreign allies, commercial OEMs, and law enforcement agencies.

Since its debut in Operation Desert Storm in 1991, LAST Armor has protected thousands of combat air and land vehicles. Today it is installed in more than 40 different aircraft types across 16 allied countries around the world, according to QinetiQ.

QinetiQ US develops and manufactures LAST Armor at its Franklin, Massachusetts facility.

“QinetiQ US is honored to partner with Integris Composites, a long-time supplier partner, to deliver a tailored, armored survivability solution for the U.S. Army’s Future Vertical Lift program,” said Christopher Forrest, executive vice president of advanced robotics and mission solutions at QinetiQ US, in a statement. “Utilizing high performance fibers and advanced ceramics, LAST Armor+ solutions offer proven traditional ballistic protection for mission success.”

Integris Composites is a global manufacturer of composite armor for land, aircraft, naval craft, radomes, protection housings for optronics, and other sensitive technology, as well as personal protection gear. The company operates its manufacturing and technical center in Licking County, Ohio.

“All of us at Integris are proud to be part of the team developing what will become the U.S. Army’s new long-range assault aircraft,” said Andrew Bonham, president of Integris Composites, Inc., in a statement. The company is the U.S. component of Integris Composites, the new name for TenCate Advanced Armour.

QinetiQ US is a defense and national security company that provides mission-led, customer-focused engineering and innovative solutions for next-generation ISR (intelligence, surveillance, and reconnaissance), advanced cyber technology, mission operations, and multi-domain autonomous systems. The company provides secure, technologically advanced services and products to the U.S. Department of Defense, Homeland Security, Intelligence Community (IC) and other national security agencies.

QinetiQ US operates under a Special Security Agreement (SSA) with the U.S. Government. As the U.S. subsidiary of QinetiQ Group plc, it maintains “independent governance and oversight to protect classified information and ensure full compliance with U.S. national security requirements,” the company said.

This material is based upon work supported by the Army Contracting Command – Redstone Arsenal under Contract No. W58RGZ-23-C-0001. Any opinions, findings and conclusions or recommendations expressed in this material are those of the author(s) and do not necessarily reflect the views of the Army Contracting Command – Redstone Arsenal.