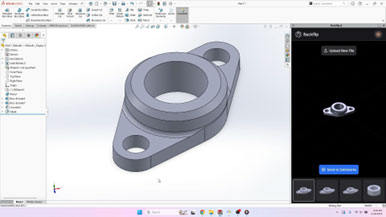

A user 3D scans a component to build a point cloud that precisely maps the surface of the part. Backflip’s technology then enables automatic conversion of the point cloud to a parametric CAD part. (Photo: Business Wire)

Backflip AI’s technology automatically creates manufacturable digital twins from 3D scans, reducing downtime and keeping plants running.

SAN FRANCISCO—A new 3D artificial intelligence (AI) model recently introduced by 3D generative AI company Backflip AI is reported to fundamentally accelerate how manufacturing plants are repaired and improved to prevent costly downtime.

The new technology enables users to automatically create 3D models of replacement parts from 3D scan data, which can then be quickly manufactured via conventional means like CNC machining or 3D printing, according to a release from Backflip AI.

The company also announced two new tools powered by this AI model. One is a plug-in for 3D industry giant SOLIDWORKS that translates 3D scan data into fully-featured parts in SOLIDWORKS’ native file format. The other is a web app that converts 3D scans into parametric CAD files. Both tools take what was once a complicated, costly process and collapse it into a simple flow that takes seconds.

Today, when a part unexpectedly breaks in a manufacturing plant and brings down a production line, a maintenance team has to quickly spring into action to get things running again. Assembly lines are composed of tens of thousands of unique parts and it’s impossible to stock an entire spare manufacturing plant. If the team doesn’t have a replacement, they often have to build a part from scratch, the release stated.

This could require someone to manually measure the part and design a digital 3D CAD model; physically manufacture that part at an internal or external machine shop; or install the replacement and restart the production line. Each of these steps can take hours, and research has shown that industrial manufacturers incur more than $50 billion in losses per year due to unexpected downtime.

“Backflip’s new tools allow manufacturers to short circuit the first step in that process in minutes, cutting downtime by as much as half, and bringing revenue-generating operations back online faster,” the company said in the release.

A $3 million per hour problem

Automotive manufacturing is a complex, synchronized ballet of tens of thousands of parts, robots, machines, and people, coming together in a mesmerizing operation of automated assembly. If even one part breaks, an entire production line goes down, at costs that can exceed $3 million per hour in lost output. When production stops, it’s “all hands on deck” to get things back up and running.

Backflip’s new technology is said to help manufacturing teams compress the time from broken parts to digital 3D models, which helps get production back online faster.

A bearing mount block is automatically reconstructed from a 3D scan with native SOLIDWORKS features, using the Backflip plug-in. (Photo: Business Wire)

Beyond automotive, factory maintenance challenges exist across the $44 trillion global manufacturing sector. Many production lines are made by third-party system integrators who don’t provide CAD models to their customers. Certain components are no longer made, and some factory machinery pre-dates the advent of digital design, especially in aerospace. As a result, manufacturing teams spend thousands of hours per year manually recreating 3D models for parts they already have in front of them.

“Backflip’s new tools eliminate this headache, automatically converting 3D scans of these parts into manufacturable CAD files in about a minute,” the release stated.

Opening the door to 3D

Backflip’s developments reduce the technical barriers to entry for designers, engineers, and technicians to recreate 3D models of parts that are missing the CAD files from which they were built. The tools also make 3D scanning significantly easier, eliminating a long-standing challenge for the technology and those who use it.

“3D scanners map the surface of an object with incredible precision, quickly generating millions of data points, but they produce micro surface textures that can’t be manufactured with traditional tools,” noted Greg Mark, CEO and co-founder of Backflip, in the release. “Our technology automatically converts these intricate surfaces into clean geometries designed for existing 3D CAD and manufacturing software.”

Teaching 3D design to new users

Backflip’s SOLIDWORKS plug-in shows each step in the process used to build a part’s geometry and generates a native feature history that users can modify. This enables CAD designers to fine tune the generated 3D model. For new users, walking through the design process helps them understand how the part was created, flattening the learning curve for designing in 3D and bringing more people into 3D CAD programs like SOLIDWORKS, the company said.

Building AI for manufacturing

The new AI model was trained on Backflip’s synthetic 3D data set of more than 100 million unique 3D geometries, which the company said is continuing to grow at an accelerating pace.

“These new developments are the result of Backflip’s continued R&D investments in neural representation of 3D data,” said Backflip Head of AI Logan Ford, in the release. “We’ve paired state-of-the-art AI/ML techniques with the team’s deep background in manufacturing to create a really powerful technology foundation. Our additional focus on resource efficiency enables us to advance rapidly, and yields 60 times more efficient training, 10 times faster inference, and 100 times the spatial resolution of existing leading methods.”

Backflip describes its work as “pioneering AI technology for the designers and engineers who create the physical infrastructure of the modern world.” The company’s AI-powered 3D design software is said to collapse the barriers between idea and implementation. It is built for creative problem-solvers across widespread industries, including mission-critical sectors like aerospace, defense, manufacturing, and transportation, the company said in the release.