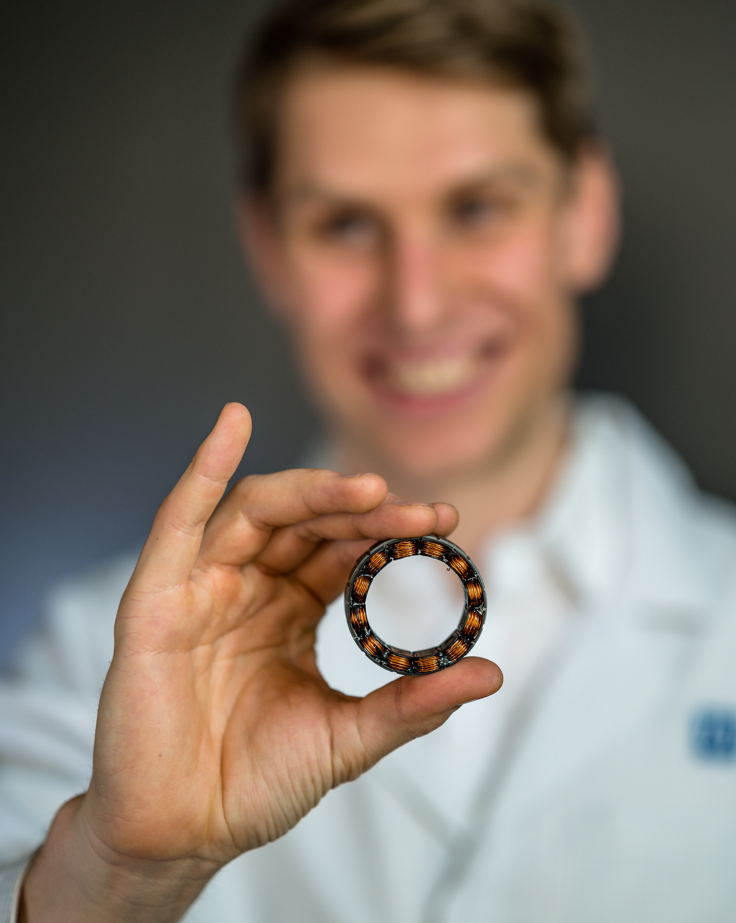

TQ-Systems USA offers frameless motors through its TQ-RoboDrive Division. (Photo courtesy TQ-Group/TQ-Systems USA)

TQ-Systems USA’s compact frameless motors provide precision and reliability in extreme environments.

CHESAPEAKE, Va.—TQ-Systems USA, Inc., an electronics engineering and manufacturing services (E2MS) provider with manufacturing operations in Chesapeake, continues to build its presence in the United States as a full, turnkey service provider.

The company employs more than 30 team members at its ISO 9001-certified production facility in Chesapeake, providing services from components sourcing to PCB assemblies to full, turnkey system assemblies and system integrations.

“We are constantly working on expanding our capabilities here,” said Brandon Aumiller, TQ-Systems USA’s Director of Sales for Embedded Products and EMS, in a February interview with Design-2-Part. “We recently added a second SMD (surface mount device) line to double our capacity here in the U.S. and we’re also looking into building an additional facility in the states.”

TQ-Systems USA is the North American arm of TQ-Group, a Germany-based electronics specialist with more than 30 years of experience in the field and approximately 650,000 square feet of production space at facilities across the globe, according to Aumiller. Its connection with TQ-Group provides TQ-Systems Systems USA with a proven, highly capable resource as it works to grow its market share in sectors like aviation, defense, medical, automation and robotics, and industrial electronics.

TQ-Group’s facilities hold quality management system certifications to ISO 9001, ISO 13485 (medical), AS9100 (aerospace), and ISO 50001 (energy management systems) standards.

“In Europe, TQ Group is one of the top 10 contract manufacturers for electronic assemblies, and we aim to bring the same level of service and support to the U.S.,” said Aumiller. “That includes providing the highest level of customer satisfaction, customer service, and quality.”

To achieve this level of service and support, TQ-Systems USA melds technology and quality in all areas of its operations. The name “TQ” stands for “Technology in Quality,” which is what TQ’s customers value most, according to Aumiller. Quality, it turns out, applies to more than the products that are manufactured.

“It starts with customer service and the desire to always go above and beyond to help our customers make their vision a reality,” he explained. “Besides always making sure we are using top-of-the-line assembly technology and keeping our staff members up-to-date on all relevant skills by constantly offering various trainings, we are also deploying AI throughout our organization to help improve efficiencies anywhere from R&D to inventory management and production planning processes. By doing so, we make sure to keep costs low for our customers and deliver the most efficient services possible.”

Among the key products fueling TQ-Systems USA’s growth are its embedded computer modules and frameless servo motors. TQ’s embedded modules are integrated into customers’ designs and typically reduce time to market by six to nine months, Aumiller said. Its frameless motors offer a combination of light weight and high torque density, giving customers greater flexibility in their product designs.

“For customers currently designing any sort of robotics applications, from medical robots to automation systems to humanoids, our frameless motors from our RoboDrive Division deliver the highest torque density on the market,” said David Hastings, TQ-Systems USA’s Director of Sales for Drive Products, in the interview.

When Hastings and Aumiller spoke with Design-2-Part in February, one of TQ’s products—a frameless motor from its RoboDrive division—had already been tabbed for use on the IDEFIX rover as part of a DLR (German Aerospace Center) mission to Mars involving the Martian Moons eXploration (MMX) spacecraft.

In addition to speaking with Design-2-Part, Hastings provided emailed responses to several questions about the project. Following are his responses.

Design-2-Part: What were the application/performance requirements?

David Hastings: The IDEFIX rover had to meet stringent weight and size constraints while maintaining full scientific exploration capabilities. As a four-legged reconnaissance vehicle, it needed to integrate all critical rover functionalities in a highly compact and lightweight design, enabling mobility on Phobos (the larger of Mars’s two moons) under extreme environmental conditions.

The locomotion system required high torque, precision, and robustness to allow for controlled movement in the ultra-low gravity of Phobos (less than one-thousandth of Earth’s gravity) to prevent unintended lifting off the surface. Additionally, the motors had to function in extreme temperatures, far below -100°C, while ensuring energy efficiency and long operational life in a harsh space environment.

D2P: What was the major technical/engineering challenge?

DH: One of the primary engineering challenges was the need to optimize every component of the rover for weight reduction while maintaining high performance. The ILM frameless servo motors from TQ played a crucial role, offering an ultra-lightweight and compact design without compromising torque or efficiency.

Another challenge was ensuring the motors’ reliability despite the extreme conditions of space, including the intense mechanical stress of being dropped from a height of 40 to 100 meters upon landing on Phobos. The motors also had to operate with exceptional precision, allowing movement at just one millimeter per second to prevent the rover from losing surface contact. Finally, achieving space qualification for the motors was essential, ensuring they could withstand radiation, temperature fluctuations, and the vacuum of space while maintaining long-term durability.

D2P: How did the company apply its services to meet the application requirements?

DH: TQ-RoboDrive’s ILM frameless motors were originally developed by the German Aerospace Center (DLR) for space applications, making them inherently suited for demanding environments like the Phobos mission.

The DLR could not find existing space-qualified motors that met their specific needs, leading to the development of ILM motors, which have since become a benchmark in aerospace drive technology.

Given this heritage, the collaboration between TQ-RoboDrive and DLR was a natural extension of the motors’ original purpose—delivering high-performance, compact, and ultra-reliable actuation in space.

The close collaboration between TQ-RoboDrive and DLR is defined by the very origin of the ILM motors, which were created to address the lack of suitable space-qualified actuators. This long-standing partnership continues to drive innovation in aerospace robotics, ensuring that missions like IDEFIX can rely on the best-in-class motor technology for space exploration.

The motors were originally made for space, but TQ has further developed the ILM series for high-volume applications in robots, humanoids, and industrial automation. As a result, the ILM-E series is a perfect match for demanding terrestrial applications, combining aerospace-grade performance with scalability for broader market adoption.

Design and Engineering

The ILM motors were designed with high torque density and precision, essential for Idefix’s locomotion on Phobos’s ultra-low gravity surface. Their frameless, compact architecture allowed direct integration into the rover’s structure, minimizing weight and volume.

Precision engineering enabled the motors to move the rover at just one millimeter per second, preventing unintended detachment from the surface due to Phobos’s weak gravity. The motors were built to withstand extreme mechanical stress, including a 40-100 meter drop onto Phobos, and still function reliably. The ILM motors had already proven their reliability in space missions, reinforcing their suitability for the MMX Rover.

Materials Used

The motors used in the IDEFIX rover are ILM frameless servo motors, explicitly designed for space applications. Lightweight and radiation-resistant materials ensure long-term performance in harsh environments. In addition, the highly efficient winding structure minimizes energy loss while maintaining maximum torque output.

Manufacturing Processes Used

The ILM motors are hand-wound, a process that optimizes coil density and enhances efficiency. Explicitly chosen pole configurations were implemented to achieve the required performance characteristics, balancing power and precision. Strict aerospace-grade assembly and quality control were applied to ensure reliability in extreme conditions.

The motors used in this project are also ideally suited for medical and other robotic applications, Hastings said.

“The same high standards we’re using to design and build our frameless motors are applied to everything we do, be it as a contract manufacturer for PCBAs or large (room sized) system solutions. Our customers can trust TQ to provide the highest level of quality and support in the industry.”