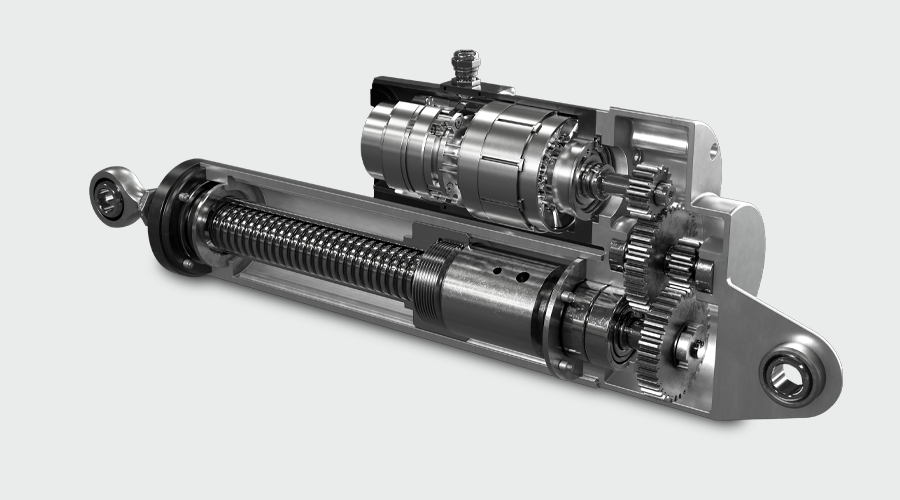

A new, next generation of electro-mechanical actuator will be manufactured by Regal Rexnord Aerospace Solutions. (Photo: Business Wire)

MILWAUKEE—Regal Rexnord Aerospace Solutions has supported flight-critical commercial and military applications with precision engineering and leading-edge motion control technologies for more than 75 years.

Today, the company is working to advance the next generation of electro-mechanical actuators (EMAs), purpose-built for the unique requirements of aerospace and defense applications. In doing so, Regal Rexnord is enabled by its family of brands, which include Rexnord Aerospace, Kollmorgen, Portescap, Nook, Thomson, Delevan, and Formsprag.

“This strategic, collaborative approach unites deep domain expertise and one of the industry’s most comprehensive motion control portfolios to deliver EMA solutions designed for optimal performance, efficiency, and operational versatility,” the company stated in a release.

The company’s expanded offering in subsystems leverages the unique strengths of its portfolio, spanning high-performance motors, rotary and oscillatory bearings, dynamic seals, resolvers, magnetics, ball and lead screws, clutches, and brakes. By uniting these core technologies under a collaborative design model, Regal Rexnord Aerospace Solutions is positioned to deliver complete EMA subsystems that are designed and tested to the most rigorous standards for reliability in extreme environments, the company said in the release.

“We’re seeing unprecedented acceleration in the shift from hydraulic to electric aircraft design. Nowhere is this growth more apparent than in the areas of advanced air mobility and electric vertical takeoff and landing (eVTOL),” said John Meyer, senior director of marketing at Regal Rexnord Aerospace Solutions, in the release. “By consolidating our trusted technologies and collaborative engineering expertise, we’re able to provide complete, performance-optimized EMA subsystems that accelerate time to market, simplify supply chains, and prioritize uncompromising quality and reliability.”

According to Regal Rexnord Aerospace Solutions, its new EMA capabilities can offer customers benefits such as seamless vertical integration, performance-optimized design, supply chain simplification, and reliability in harsh environments.

The company’s products are designed and manufactured in-house at one or more of its 12 global AS9100-certified facilities, enabling accelerated transitions from prototyping to full-scale production. Access to Regal Rexnord Aerospace Solutions’ comprehensive motion control building blocks is reported to streamline engineering, enabling tailored actuator systems that are positioned to meet stringent aerospace and defense specifications.

Electro-mechanical actuator subsystems, designed primarily with components from the Regal Rexnord Aerospace Solutions family of brands, are said to reduce the need to source and manage components from multiple suppliers. This reduces complexity and accelerates time to market. In addition, each system undergoes rigorous testing for compliance and durability, enabling mission-critical performance under extreme conditions of shock, vibration, and temperature.

Collaborative application expertise and sustainable design are among the other benefits available to customers. Regal Rexnord Aerospace Solutions’ engineering teams engage directly with customers to solve their most complex design challenges, rapidly adapting proven technologies for unique application requirements across commercial aerospace, defense, and emerging sectors, such as advanced air mobility and eVTOL.

In addition, electro-mechanical actuation offers inherent benefits over traditional hydraulic solutions, enabling the conservation of resources through low-weight design, increased reliability, and longer lifetimes.

“We are proud to play a role in accelerating innovation in aircraft design, and we have a lot more to offer,” said Regal Rexnord Executive Vice President and President, Automation & Motion Control Segment, Kevin Zaba, in a statement. “This new EMA capability is just one example of the overall Regal Rexnord strategy for delivering exceptional value to customers through advanced solutions that enhance performance and promote sustainability. From aerospace to robotics to factory automation, we’re a strategic partner helping bring today’s most important innovations to life.”

Regal Rexnord makes products that power, transmit, and control motion. The company’s technologies range from high-performance motion control systems in surgical robots and satellites, to advanced automation and precision-engineered components that optimize efficiency, from factory floors to renewable energy.

Its global team of professionals, supported by a worldwide network of design and manufacturing centers, collaborates closely with customers to deliver “tailored solutions that fuel innovation across a broad range of industries including robotics, aerospace, medical, agriculture, and more.”