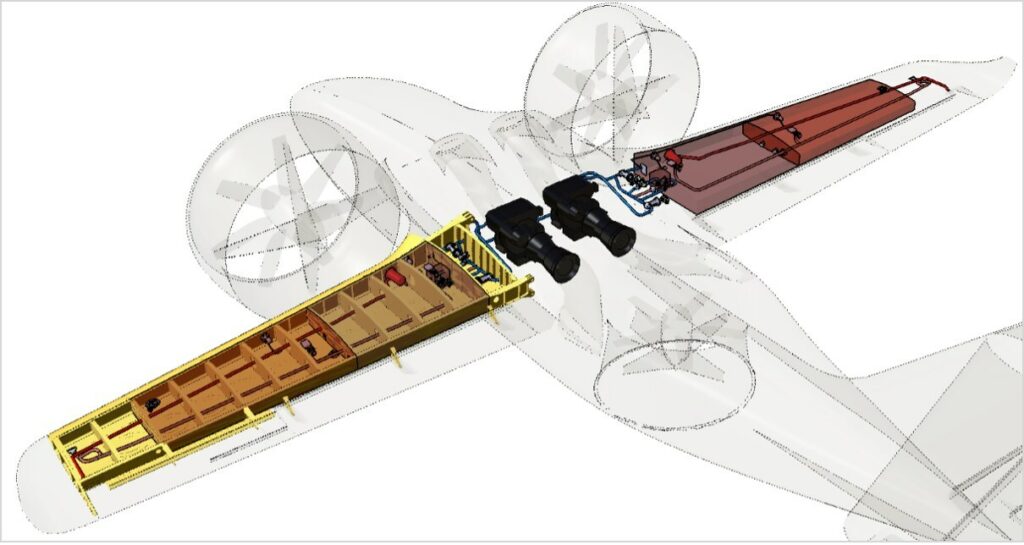

The updated global finite element model (GFEM) for the latest configuration of XTI Aerospace’s TriFan 600 fixed-wing business aircraft. (Image courtesy XTI Aerospace, Inc./PRNewswire)

The company also updated the aircraft’s fuel system design, optimizing it to reduce unusable fuel and increase fuel capacity.

ENGLEWOOD, Colo.—XTI Aerospace, Inc. recently achieved a key first-quarter product and engineering milestone by completing its global finite element model (GFEM) for the latest configuration of its TriFan 600 fixed-wing business aircraft. The achievement advances the design team’s ability to perform further structural integrity and load distribution analysis, the company said in a release.

XTI Aerospace, a pioneer in vertical takeoff and landing (VTOL) and powered-lift aircraft, is the parent company of XTI Aircraft Company, an aviation business based near Denver that is currently developing the TriFan 600. The aircraft is designed to have the vertical takeoff and landing capability of a helicopter, speeds of 345 mph, and a range of 700 miles. As such, it is said to create what XTI described as “an entirely new category—the vertical lift crossover airplane (VLCA).”

The GFEM represents the next level of detail for the Digital Mock-up (DMU), or “digital twin,” within the highly detailed CATIA 3DX computer aided design model of the TriFan 600. The GFEM’s completion enables the team to further analyze the underlying structural integrity and load paths in the aircraft before finalizing the detailed finite element model, according to the release.

“The DMU and GFEM allows us to do detailed analysis of our design in terms of structure and mass properties,” said Dave Ambrose, vice president of engineering at XTI Aircraft, in the release. “Our structures team is eager to begin the next phase of validation and modification of our internal structures of the aircraft. Just as the CFD (computational fluid dynamics) informs the aerodynamic performance of the aircraft, the GFEM enables a deeper understanding of structural integrity and load distribution.”

“The completion of the GFEM is an important step in advancing the digital analysis of the TriFan 600,” said Scott Pomeroy, chairman and CEO of XTI Aerospace, in a statement. “Our engineering team is driving forward with detailed design refinements—focusing on structures, load paths, weights, and part optimization—all while maintaining commitment to safety and performance.”

XTI reported that in the first quarter of 2025, it successfully completed all six product and engineering milestones, beginning with the downwash/outwash study. In this study, XTI engineers analyzed airflows generated by the aircraft during vertical takeoff and landing to evaluate safety and performance.

An overview of the TriFan 600 fuel system design. (Image courtesy XTI Aerospace, Inc./PRNewswire)

The milestones also include a formal application to the FAA for type certification of the TriFan 600; optimization of engine air intake and exhaust design to enhance performance and efficiency of the propulsion system; optimization of fuel system design to reduce unusable fuel and increase fuel capacity; and development of a flight deck human factors mockup to design and evaluate and optimize ergonomics, pilot controls, and vision polar. All of these milestones are leading up the launch of the “Sparrow” subscale working model in the early part of the second quarter, the company said.

The updated fuel system design is reported to significantly increase fuel volume in the wings from approximately 300 gallons to 400 gallons, while minimizing unusable fuel in the system.

“The TriFan 600 continues to mature in its design, and in the case of the fuel system, we expect to exceed our performance criteria target,” said Ambrose. “We believe this latest fuel system design will significantly improve the maximum range and endurance of the vehicle.”

“Our engineering team continues to innovate while remaining laser-focused on our customers’ missions,” said Scott Pomeroy, chairman and CEO of XTI Aerospace. “We believe the new fuel system is designed to improve the range of the TriFan 600 aircraft and to exceed our previous design.”