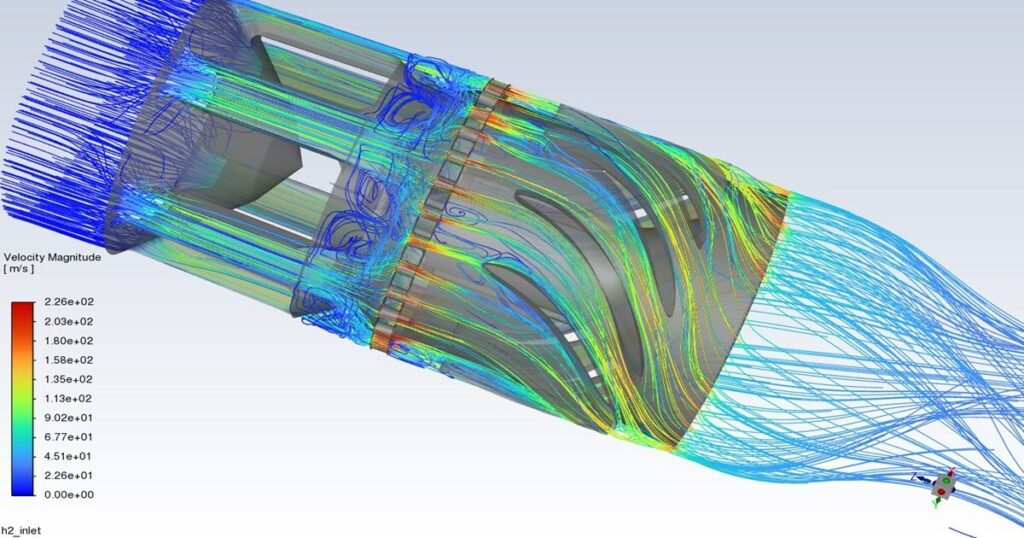

Path lines of dihydrogen flowing through the injector, swirled by blades inside the canal. (Image courtesy Ansys/PRNewswire)

Turbotech integrates Ansys simulation across its designs from component to system, creating a digital thread that drives time and cost savings when developing hydrogen propulsion systems.

PITTSBURGH—A supplier of efficient and sustainable aviation systems is leveraging Ansys simulation software to deliver what is reportedly “the first viable hydrogen-fueled turbine engine for small-scale passenger planes, vertical takeoff and landing (VTOL) vehicles, and drones,” Ansys stated in a release.

Turbotech, in partnership with the BeautHyFuel project, is the first company to successfully demonstrate a hydrogen-fueled turboprop engine, according to the release. The achievement is said to highlight “the crucial role of Ansys simulation in advancing next-generation technology.”

Exploratory turbine designs struggle to safely and reliably use hydrogen as a fuel, making it difficult to balance power output, fuel consumption, heat, and combustion systems service life. Turbotech takes a scalable approach, using Ansys simulation to help design and validate a gas turbine that is fuel agnostic. This approach is said to support an easier, streamlined transition to hydrogen.

According to Ansys, simulation-led product development allowed Turbotech to quickly identify the two best nozzle designs for real-world testing. The approach reduced prototyping costs and timelines.

Specifically, Fluent delivered critical high-fidelity predictions of the flame shape and temperature. After 30 hours of hydrogen burn, the nozzles retained nearly identical structural integrity, and the turbine did not increase emissions output. Ansys solvers also enabled Turbotech to run these simulations on boosted workstations, avoiding the need for large clusters traditionally required for combustion modeling, the release stated.

Turbotech first developed a novel regenerative turbine through the Ansys Startup Program. This work helped pave the way for a digital thread that is said to seamlessly connect and manage data, ultimately enabling the retrofit for hydrogen.

“Turbotech’s goal is to bring a built-in, deeply integrated solution to the light aviation market that reduces carbon emissions and empowers pilots to focus solely on flying,” said Guillaume Malet, chief technology officer at Turbotech, in the release. “The reliability of Ansys helped us tremendously throughout the redesign, successfully allowing us to retrofit the turbine for hydrogen on a much shorter timeline. It would not have been feasible to test or optimize our prototypes without Ansys simulation.”

This series of tests is part of the BeautHyFuel project, supported by the French Civil Aviation Authority and led by Turbotech and Elixir Aircraft, in partnership with Safran, Air Liquide, and Daher.

“Ansys is dedicated to supporting customers like Turbotech in expanding the limits of what can be achieved through simulation,” said Walt Hearn, senior vice president of customer excellence and worldwide sales at Ansys, in the release. “This first-pass success was made possible not only by Turbotech’s expert engineers and their deep understanding of complex multiphysics, but by Ansys’s strong technical support across all phases of the project. The collaboration is critical to helping Turbotech save significant time, costs, and resources as they advance this new market.”