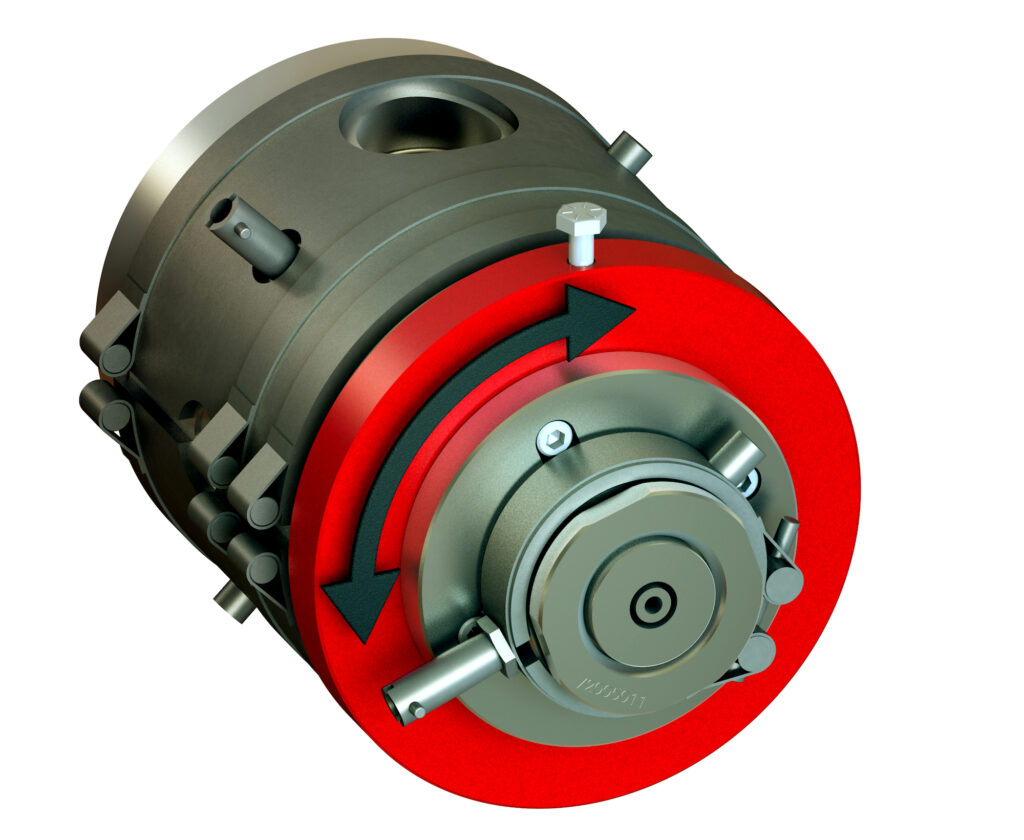

The Guill Single Point Concentricity design is described by Guill as “a unique Guill innovation for the extrusion of thin-walled jacketing and precision ID/OD tubing.” (Image courtesy Guill Tool & Engineering)

The crosshead includes a patented deflector that is said to offer significant time, labor, and cost savings.

WEST WARWICK, R.I.—Guill Tool & Engineering, a designer and manufacturer of plastic extrusion tooling, recently introduced an extrusion crosshead that uses micro-fine adjustment screws for precise concentricity adjustment, the company said in a release.

The concentricity provided by Guill’s Single Point Concentricity extrusion crosshead reaches 0.008 inch, or finer, per revolution. It is one of multiple methods that Guill offers for “adjusting concentricity to maximize the desired amount of pressure applied to a substrate between the tip and die,” according to the company’s website.

“This single point concentricity adjustment is a unique Guill innovation for the extrusion of thin-walled jacketing and precision ID/OD tubing,” the release stated. “One adjustment bolt controls 360° of adjustment.”

The Single Point Concentricity extrusion crosshead includes the patented Cam-Lock deflector for quick changeovers, with a residence time of one minute at 0.5 pound per hour of material flow; optimized usage with extruders measuring ½ inch and ¾ inch; and a maximum die ID of 0.250 inch. The Guill single-point crosshead accepts both vacuum and micro-air accessories and is also said to be suitable for pressure and sleeving applications. Fluoropolymer designs are available upon request, the company said.

Cam-Lock is now available on many of Guill’s existing extrusion heads, the company said. Cam-Lock was originally developed for the Guill Bullet tool, which the company described as “a unique Guill extrusion head that eliminates fastening hardware with a fixed center design, multi-port spiral flow, and gum space adjustment.”

“The design allows quick and easy assembly and disassembly of the crosshead and eliminates the need for socket head caps screws,” the release said. “By removing and replacing the internals, a different profile can be extruded in minutes rather than hours.”

According to Guill, the Cam-Lock resets the internals in the right configuration every time, resulting in much less chance of error compared to the assembly and misalignment issues with torqued socket set screws. It only takes half a turn to remove and install the deflector tip, and no fastening hardware is required.

The Single Point Concentricity extrusion crosshead includes the patented Cam-Lock deflector for quick changeovers. (Image courtesy Guill Tool & Engineering)

Fast tool changes are possible due to a threaded retaining ring for the die and a threaded tip retainer. Dies remove from the front; tips, from the back. Additional features include tooling retainers for gum space adjustment, vacuum connections, simplified cleaning, and reduced downtime and operating costs, the company said in the release.

“For a busy shop with multiple products produced or a shop processing challenging materials that require frequent cleaning, this Cam-Lock feature on Guill heads offers significant time, labor, and cost savings,” the release stated.

Guill Tool & Engineering is planning to exhibit these products, along with other tools, tips, and dies, at the K Show in October. The international trade fair for the plastics and rubber industry will be held in Düsseldorf, Germany.