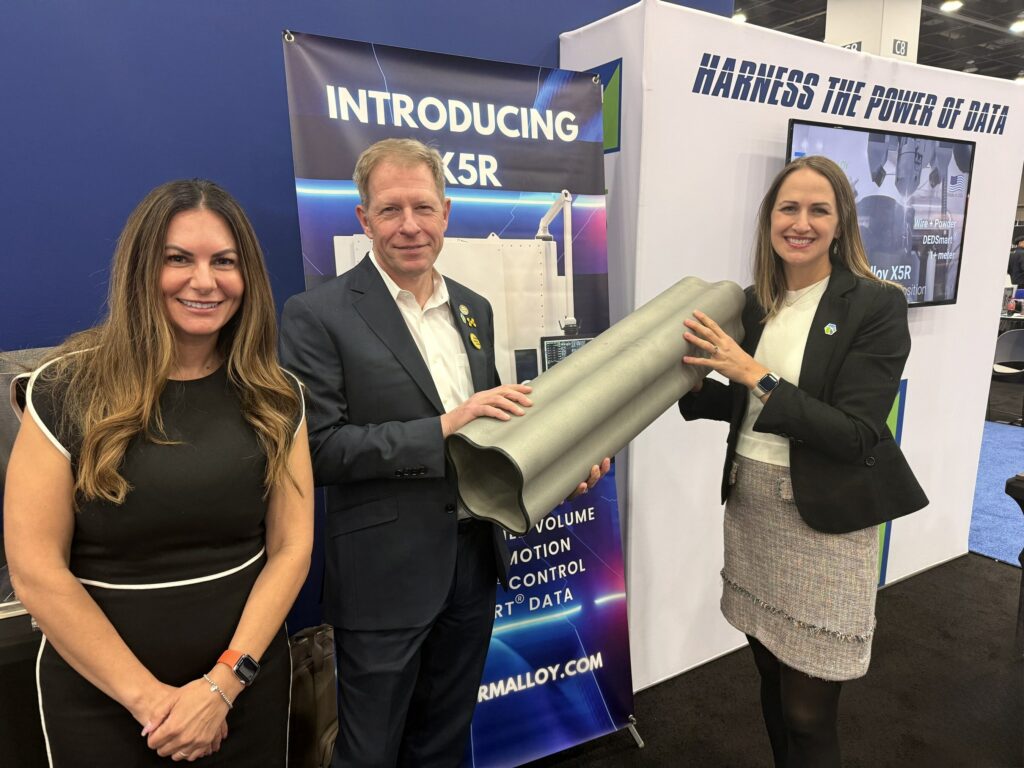

(Left to right) FormAlloy CEO Melanie Lang, along with John Barnes and Jennifer Coyne, both of The Barnes Global Advisors. (Photo: The Barnes Global Advisors / PRNewswire)

HAMR Industries will manage and operate the additive manufacturing system in support of defense applications.

PITTSBURGH—The advanced manufacturing hub Neighborhood 91 will be adding to its capacity with the addition of a FormAlloy X5R Directed Energy Deposition (DED) system, according to a release from Neighborhood 91.

Neighborhood 91 is an advanced manufacturing production hub located at the Pittsburgh Airport Innovation Campus. It was “created to bring efficiency to additive manufacturing by co-locating key supply chain partners,” according to Neighborhood 91’s website.

“From powder production to post-processing, every step happens in one place, reducing costs and lead times,” the website stated.

Although FormAlloy systems have been in the market since 2017, the delivery of the X5R will reportedly mark the first deployment of the advanced additive manufacturing technology with a robotic arm. An X5R system is currently in operation at FormAlloy’s Application Development Center in San Diego, California, the release stated.

The acquisition of the X5R DED system was made possible through the Resilient Manufacturing Ecosystem (RME) program, managed by The Barnes Global Advisors (TBGA) and funded by the U.S. Department of Defense (DoD) through its Industrial Base Analysis and Sustainment (IBAS) program. The RME program was established to “derisk the adoption of advanced manufacturing to fulfill the needs of the DoD,” according to the release.

HAMR Industries will operate the X5R system to develop next-generation components designed for extreme environments, with a focus on propulsion, hypersonics, and to support the Maritime Industrial Base (MIB) advanced manufacturing initiatives.

“The ability for the X5R to operate with multiple feedstocks, build meter-sized components, and functional grade is a huge advantage,” said Michael Schmitt, CEO of HAMR Industries, in a statement. “We expect to utilize both wire and powder capabilities to balance economics with part size and complexity, while functional graded materials will be used for a variety of high-performance applications.”

A standout feature of the X5R is its integrated robotic arm, which extends the system’s build volume.

“We saw the demand signal from industry for scalable DED,” said Melanie Lang, CEO of FormAlloy, in the release. “The development of this robotic arm enables a significant increase in build volume, meeting industry needs for larger and more complex components.”

Jennifer Coyne, director of operations at The Barnes Global Advisors, emphasized the broader significance of the acquisition.

“RME was established as a model to demonstrate how to structure a sustainable advanced manufacturing supply chain,” Coyne said in the release. “The ability to integrate innovative equipment like the X5R provides immense value to moving this endeavor forward.”

The installation at Neighborhood 91 is said to reinforce the site’s growing role as a hub for advanced manufacturing innovation and supply chain advancement in the United States. The X5R will be introduced later this year when the campus hosts its first Defense Day Open House, the release stated.