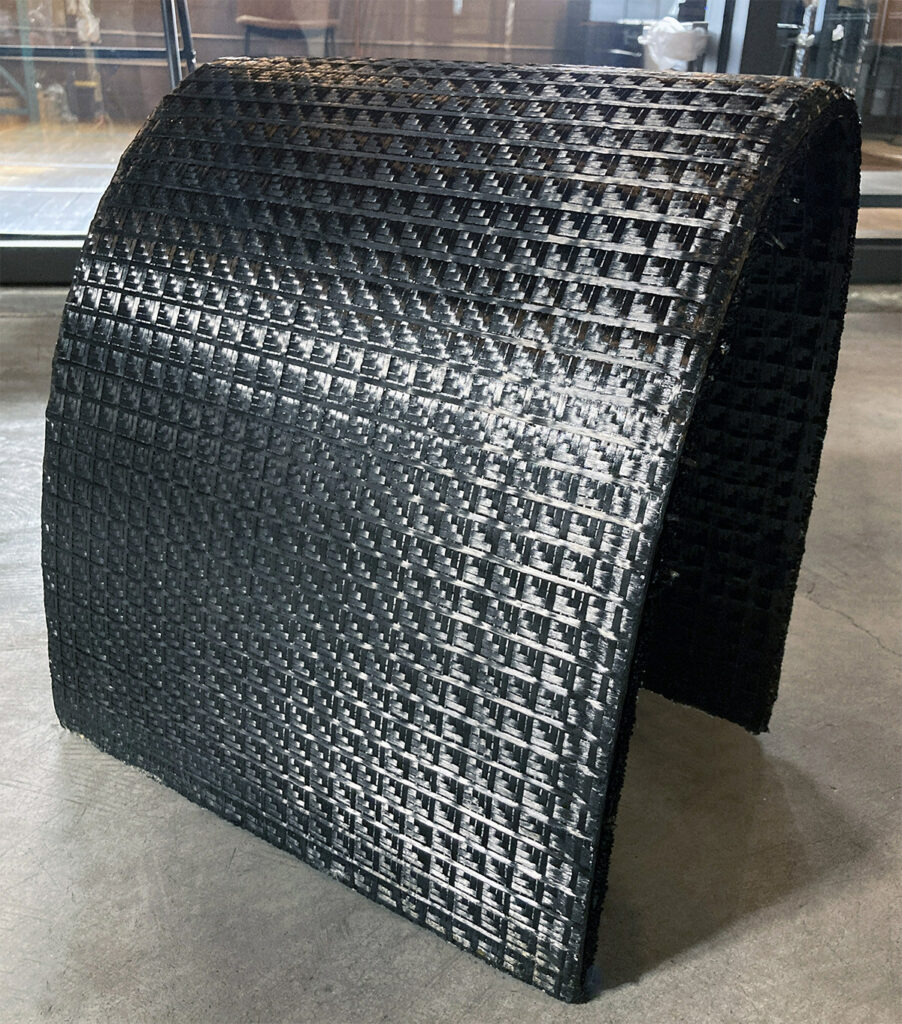

The completed Fiber Architecture Leading Edge, printed by Continuous Composites using its CF3D technology. (Image: Continuous Composites/PR Newswire)

The company will work to advance the development of high-performance materials using a patented technology that offers precise control over fiber orientation and geometry.

COEUR D’ALENE, Idaho—Continuous Composites (CCI) is working to redefine composite manufacturing with its patented Continuous Fiber 3D technology, CF3D®. The advanced materials technology integrates fiber steering and automated manufacturing, enabling the production of lightweight, high-performance structures with high levels of precision and scalability, according to CCI.

“This innovative approach transforms how complex components are made, unlocking new possibilities across aerospace, defense, and UAV sectors,” the company said in a release.

Continuous Composites announced in July that it was awarded multi-million-dollar funding from the U.S. Air Force as part of a multi-year contract to advance the development of high-performance materials using its CF3D technology. The funding is divided into two phases.

The first phase, already underway, is said to focus on establishing baseline material properties and a performance validation campaign to benchmark CF3D-produced components against traditional manufacturing methods, such as those used for materials like Carbon-Carbon. The second phase of the funding will support the expansion of this work, enabling full-scale component production and flight testing, according to the release.

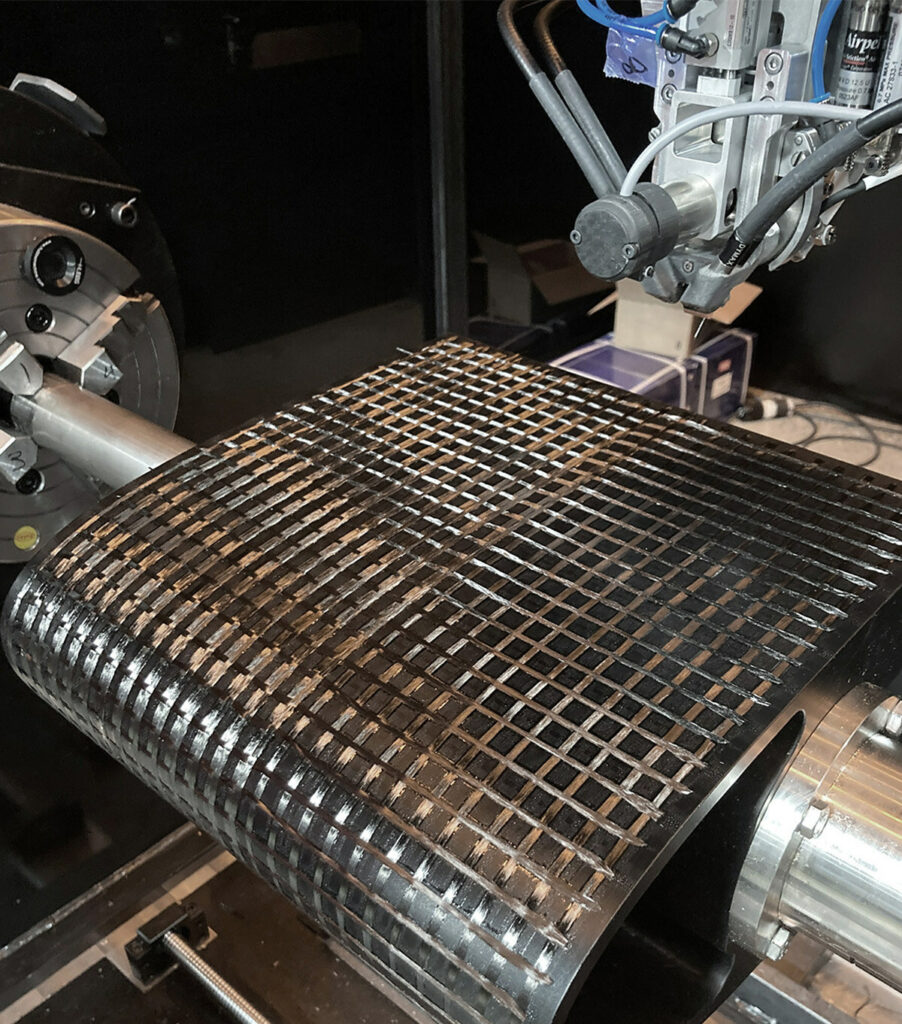

Fiber Architecture Leading Edge is shown printing on Continuous Composites’ 7th-axis mandrel. (Image: Continuous Composites/PR Newswire)

“This phase will allow CCI to refine production processes, conduct additional testing, and further advance CF3D’s capabilities for high-temperature applications,” the release stated.

By enabling automated manufacturing of continuous fiber composites in near-net shapes, CF3D technology is reported to offer precise control over fiber orientation and geometry.

“This capability facilitates the scalable production of complex parts with enhanced design flexibility and the ability to meet the high-performance requirements of high-temperature applications,” the company said in the release.