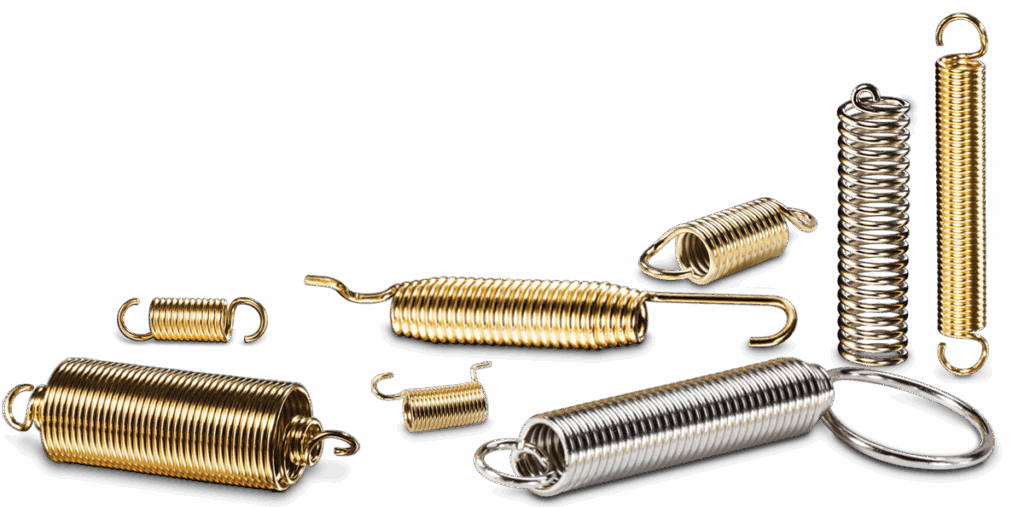

One of Newcomb Spring’s specialties is the manufacture of custom extension springs, a sampling of which is shown here. (Image courtesy Newcomb Spring Corp.)

Newcomb Spring’s eight strategically located facilities enable it to adapt quickly and keep production going with minimal interruption in customer schedules.

By Mark Shortt

ALPHARETTA, Ga.—If you’ve ever experienced a production delay due to a supplier’s bottleneck, you know how difficult it can be to get back on track. It’s the type of situation that custom metal form and spring manufacturer Newcomb Spring is built to remedy.

Newcomb Spring has a history of over 130 years and describes itself as “one of North America’s largest and most experienced custom spring and wire form manufacturers.” According to the company, its ability to adapt quickly to schedule changes sets it apart from others in the industry.

“As a supplier and partner to OEMs and product manufacturers, our company’s greatest strength lies in our extensive network of eight strategically located facilities, which allows for rapid turnaround times and increased capacity,” said Newcomb Spring Corporate Sales Manager, John Newman, in an emailed response to Design-2-Part. “This network, coupled with our exceptional design assistance, positions us as the preferred choice for our customers.”

Newcomb Spring’s large network enables it to leverage resources across all eight locations. If one facility faces a bottleneck, another can take over with little delay, allowing for continuous production flow. If an unexpected interruption occurs where one division is located, whether due to natural disaster or another unforeseen conflict, one of its other divisions can pick up the production with minimal interruption in customer schedules, according to the company.

“If a supplier is working with a single source manufacturer and this occurs, the vital production schedule could be set back for weeks, months, or longer,” Newman said. “As a multi-source company, we have disaster mitigation plans to assist if these circumstances arise. We act as a multi-source supplier while simplifying procurement by requiring orders to only one destination. Our inventory management and reliability allow us to maintain stock and fulfill orders based on our supplier’s plan, helping us to meet customer needs efficiently and effectively. We are not just eight plants; we are ‘One Newcomb.’”

The company’s eight manufacturing plants, all with varying capacities, are located in Ontario, Canada; Southington, Connecticut; Gastonia, North Carolina; Stonecrest, Georgia; Dallas, Texas; Ooltewah, Tennessee; Denver, Colorado; and Stanton, California. They offer approximately 500,000 square feet of combined workspace.

Newcomb Spring specializes in producing custom OEM parts tailored to meet the specific needs of product manufacturers across various sectors. Although the company also creates maintenance and service components, the majority of its work consists of original equipment manufacturing.

“Our custom parts are crafted to precise specifications, allowing for their seamless integration into the applications for which they are designed, enhancing performance and durability,” said Newcomb Spring of Tennessee GM, Jason Bingham.

Custom parts produced by Newcomb Spring include a wide array of precision compression springs, extension springs, and torsion springs. The company also manufactures a variety of flat springs, wire forms, and stamped metal parts, among many others.

Comprehensive design, engineering, and manufacturing services

The company supports a wide range of industry sectors, from aerospace, agriculture, and appliances, to automotive, construction, defense, office equipment, telecommunications, and oil and gas field operations. Manufacturers of fasteners, hardware, medical equipment, mining equipment, sporting goods, and outdoor power equipment are also among the company’s customers.

“If there’s an industry you can think of, it’s likely that we have experience in it,” Newman said.

That experience includes providing what the company describes as “comprehensive design, engineering, and manufacturing services.” Newcomb Spring assists customers from initial concept phase through prototyping and production of the finished product. Its services include optimizing designs to improve fit, reduce costs, enhance strength, and extend the lifespan of parts.

Newcomb Spring encourages customers’ early involvement in the design process to streamline development and reduce costs by identifying potential issues early. To assist customers in their spring design process, Newcomb offers a complimentary spring design calculator on its website, along with an app version.

Dubbed the Springulator®, the tool provides calculations for compression, extension, and torsion springs. It enables users to calculate spring design specifications, check stresses, and test capabilities. Engineering support is available on-site and virtually.

“You can input your specifications and request a quote from our company with your inputs as well,” Bingham said. “It includes easy-to-use functions, reference diagrams, and stress charting.”

Leveraging advanced technology to enhance precision and quality

By making extensive use of automation in its manufacturing processes, Newcomb Spring is able to minimize human error while enhancing efficiency and precision from initial production to final inspection. The company employs a variety of advanced technologies, including vision systems and statistical process controls.

“These systems are integral to our operations and feature a mix of proprietary technology developed by our company, and advanced technology offered on the market,” Bingham explained. “Many can auto-adjust machines based on real-time feedback, helping parts to meet stringent quality standards.”

Laser technology, proximity sensors, and automatic feeding grinders contribute to precise machining and handling of materials, further reducing the likelihood of errors. Robotic automation is also used: Machine robots measure, transport, and pack parts, streamlining the workflow and reducing manual labor.

Many of Newcomb Spring’s machines are equipped with vision systems for 100 percent inspection of parts right off the machine. Its manufacturing team also implements Statistical Process Controls (SPC) to monitor and control the quality of production lots. This real-time monitoring, coupled with auto-sorting technology, allows them to detect and address issues promptly, significantly reducing defect rates.

The company also uses the Process Capability Index (Cpk) to analyze the performance consistency of its springs.

“A Cpk analysis helps us understand how close the process is to its specification limits and the consistency of our output,” Bingham explained. “If variations are detected, indicating that the process isn’t meeting specifications, we conduct a thorough review and make necessary adjustments to refine our processes and improve product quality.”

Boosting throughput and reliability in a medical device customer’s high-velocity manufacturing line

For one customer, Newcomb Spring took on a significant challenge in their production of high-volume medical injection devices. The devices require precision engineering due to their involvement in high-velocity automation systems.

The primary technical challenge stemmed from the typical dimensional variation that could cause downtime and inefficiencies in the systems. The goal was to optimize throughput and eliminate downtime caused by natural process variations. This required implementing solutions that would allow the devices to operate at peak efficiency consistently, without interruptions.

“The main technical hurdle was developing the controls necessary to deliver high volumes of product with dimensional variations within less than 50 percent of the previously accepted tolerance,” said Newcomb Spring of North Carolina GM, Keith Porter Jr. “This stringent requirement was crucial to eliminating the automation challenges and optimizing throughput.”

Newcomb Spring conducted a thorough evaluation of automation failure modes and identified the primary causes of failures linked to dimensional variations. Its engineering team then developed and implemented more precise process controls, effectively reducing critical-to-assembly (CTA) tolerances by more than 50 percent.

The route to success included visiting the customer’s site over a three-month period to make real-time adjustments and improvements, confirming that the new tolerances effectively addressed the existing automation challenges.

“As a result of these interventions, our customer experienced a significant reduction in downtime,” Porter Jr. said. “The improvements in precision and process control directly translated into enhanced throughput and reliability in high-velocity manufacturing lines for medical injection devices. This project not only demonstrates our firm’s capability in solving complex technical challenges, but also our commitment to delivering high-quality, reliable solutions in critical medical applications.”

The company has also developed and built customized coiling and forming equipment for specific applications. By creating a highly specialized, custom machine, Newcomb Spring can optimize run speeds and maintain tighter tolerances to provide a superior product at a competitive price, Porter Jr. said.

“Currently, our R&D department is building a custom load cycle tester, as well as a spring setting machine. We are always looking for ways to improve the technology that we utilize for more efficient and specialized processes,” he concluded.