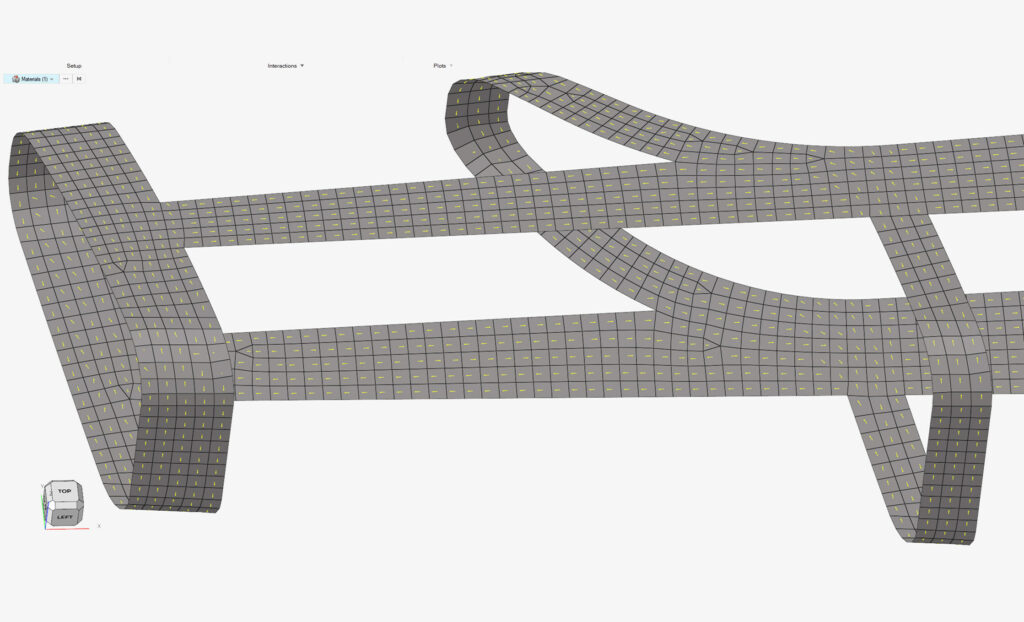

CF3D anisotropic fiber orientations are mapped onto a Finite Element Mesh (FEM) using CF3D Studio™. (Image: Continuous Composites/PRNewswire)

The company is working to develop a new tool to accurately simulate how its parts will behave under various conditions.

COEUR D’ALENE, Idaho—Continuous Composites (CCI) was recently awarded a $1.9 million Tactical Funding Increase (TACFI) contract from the U.S. Air Force to develop a groundbreaking Finite Element Analysis (FEA) tool for Continuous Fiber 3D Printing (CF3D), the company said in a release.

The contract, which started in November 2024 and will run through August 2026, reportedly represents “a significant advancement in the simulation of anisotropic composite materials, which have unique directional strengths based on fiber orientations.”

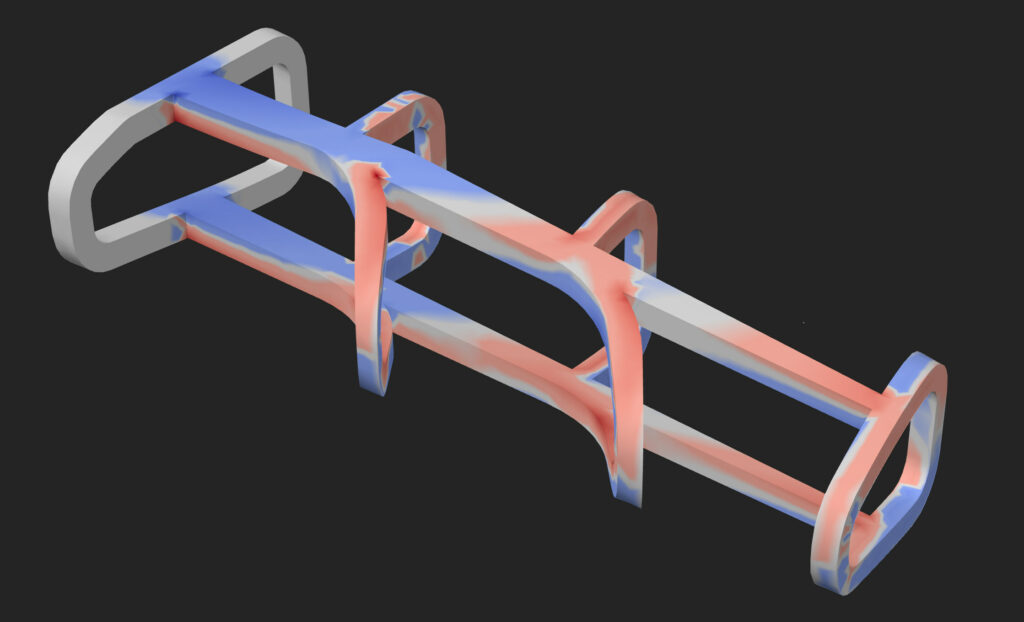

According to the release, commercially available FEA tools are currently limited to isotropic materials, such as metals, where strength and stress responses are uniform in all directions. However, CF3D® composites are anisotropic, with primary strength in the direction of the fibers. This creates a challenge for traditional FEA software, which cannot accurately predict material behavior based on fiber orientation.

A heat map showing stress and strain distribution across the geometry under the applied load. (Image: Continuous Composites/PRNewswire)

“We’re solving a major gap in FEA simulation tools,” said Steve Starner, CEO of Continuous Composites, in a statement. “Existing software only assigns a single directional property to each layer of composite material, but CF3D’s fiber steering requires a more dynamic approach. Our new tool will accurately simulate how our parts will behave under various conditions, which is crucial for industries like aerospace and defense.”

Continuous Composites is partnering with industry experts on the development of the new FEA tool. The tool will ingest CF3D toolpath data to generate mesh representations that more accurately reflect fiber orientation, material behavior, and structural performance of how anisotropic parts will react to real-world loads, the company said.

As part of this effort, Continuous Composites will integrate the new tool into CF3D Studio™, enabling the prediction of material properties and performance before physical testing begins. This capability is expected to dramatically reduce development time and increase reliability in the design of complex composite parts used in mission-critical applications.

The contract is said to be a major milestone for Continuous Composites, “advancing CF3D technology from a manufacturing process to a comprehensive design-to-performance solution,” the company said.

“The development of this tool represents a significant leap forward in the simulation of high-performance, lightweight composite parts, with potential applications across the aerospace, defense, and UAV industries,” the release stated.