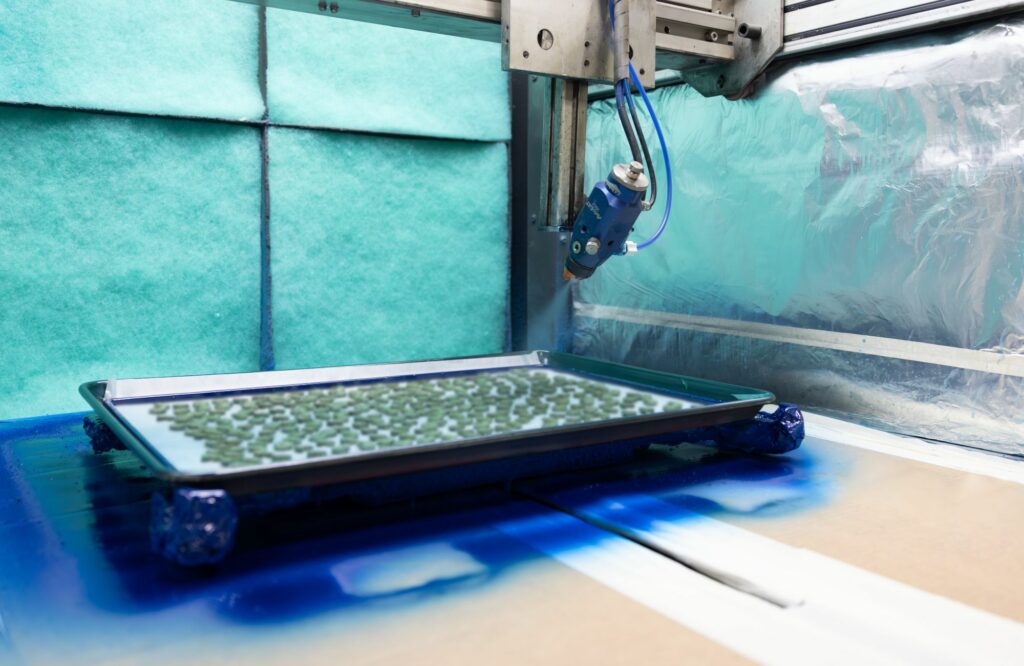

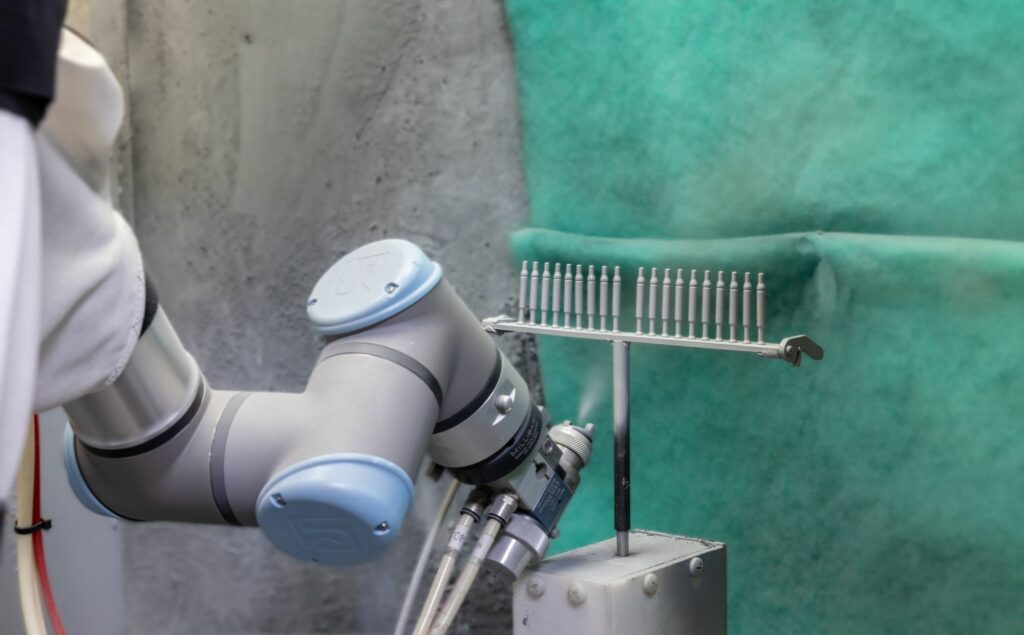

Orion Industries uses robotic equipment to hold tight tolerances on coatings that improve the performance of parts in extreme temperatures and environments.

Orion Industries uses robotic equipment to hold tight tolerances on coatings that improve the performance of parts in extreme temperatures and environments.

By Mark Langlois

Orion Industries is a 60-year-old high-performance coating company that got its start in the early 1960s coating parts to speed up race cars. Today, the Chicago-based company is coating aerospace and defense materials for use in outer space, in defense machinery and munitions, and on the ocean, as well as coating parts for most industries and markets.

“Orion doesn’t produce parts; we provide functional industrial coating services,” said Patty Martucci, Orion Industries marketing manager, in an emailed response to Design-2-Part.

Orion’s coatings are essential for parts that perform in extreme environments and temperatures—for example, up to 270 degrees Celsius or as cold as minus 270 degrees Celsius. In addition to helping parts withstand harsh environments, its coatings increase resistance to wear, abrasion, and corrosion, and their lubricity helps reduce friction.

They also help customers hold tight coating tolerances, a key attribute when parts expand and contract in extreme temperatures. As an example, Orion’s coatings are the choice for an industry that puts a valve in the desert and leaves it unattended, fully expecting it to work in eight or 10 years.

“We have the expertise to apply over 100 different coatings for a variety of unique applications,” said George Osterhout, former company president, now senior advisor to Orion Industries. “Our in-house coating lab with an experienced chemist and staff, gives us the unique ability to formulate our coatings for specific customer needs. After we fully understand the customer’s technical and use-case requirements, we determine the right coating formulation and application process to resolve issues such as friction, adhesion, product release, corrosion, noise, heat, and abrasion to improve the performance of their finished products and components.”

Orion employs more than 100 people in two facilities. The company expanded in 2014 into a 68,000 square-foot facility at 5492 N. Northwest Highway in Chicago, while maintaining its previous production facility at 5170 N. Northwest Highway. It employs numerous long-term team members with decades of service, and it has retained key technical staff, giving it the ability to apply solutions learned from old customer projects to new challenges.

Orion Industries is AS9100D and ISO 9001: 2015 certified, as well as ITAR registered. The AS9100D certification gives global recognition to a firm that meets the highest aerospace quality standards by offering excellent parts and services. Most defense OEMs won’t accept work from a company without the AS9100D certification.

In addition to the ability to repeatedly produce consistent, high-quality results, one of the certification’s many quality requirements is designed to stop the use of counterfeit parts in the aerospace supply chain. It is based on an internationally understood and followed quality management system. To meet the standard, Orion maintains consistent, repeatable high quality, and promotes a continuous quality improvement culture inside the company. This certification opens the doors to selling to major original equipment manufacturers.

“Orion creates greater product performance through functional industrial coatings. This means consistent, repeatable results, long lasting customer partnerships, a people-focused culture, and the courage to go beyond expectations,” Martucci said. “We use over 100 quality control devices and tools for measuring and testing specific part and coating parameters.”

Orion Industries serves primarily large and mid-size manufacturers and component suppliers in a wide variety of industries beyond aerospace and defense, such as automotive and marine, chemical, and material processing, food processing, cookware, bakeware, industrial and manufacturing, water service, and others.

The right coating arises from the right questions

Scott Yoder, Orion Industries’ regional sales manager, explained that an important step in Orion’s coating process is figuring out what the customer wants to do. “We use a lead risk assessment form,” Yoder said. “A customer reaches out through a call or the internet. Our job is to listen. [If they say] they want a particular type of coating, we start digging.”

Yoder said Orion keeps asking questions, and the answers lead to coating decisions. A critical step in this process is pretreating the material to make certain it can be coated properly.

Maybe the customer calls and says they want to coat trays with a PTFE-type coating. Orion begins asking questions. Are the trays exposed to protein? If so, that protein might get under the coating. Or maybe the customer needs something that forms an actual barrier so the protein doesn’t get underneath and cause delamination. Yoder asks about the use: What are some of the conditions? Are there chemicals, water? What is the part? What is it exposed to? What are the temperatures? What type of frictional forces are applied to it? Are there any electrical requirements? What kind of wear and abrasion?

Maybe the customer calls and says they want to coat trays with a PTFE-type coating. Orion begins asking questions. Are the trays exposed to protein? If so, that protein might get under the coating. Or maybe the customer needs something that forms an actual barrier so the protein doesn’t get underneath and cause delamination. Yoder asks about the use: What are some of the conditions? Are there chemicals, water? What is the part? What is it exposed to? What are the temperatures? What type of frictional forces are applied to it? Are there any electrical requirements? What kind of wear and abrasion?

Once Yoder hears the answers, Orion can pick options.

Once Yoder hears the answers, Orion can pick options.

“As a coater, the most important thing we can do is pretreat a part. That way, we know exactly how a part was done,” Osterhout said. Orion knows how to pretreat a material because it has been working at it for more than 60 years. The actual steps depend on the material. Some can be chemically washed. Some can be mechanically abraded and some can be heat-treated before coating.

Orion Industries uses automation and robotics to make the coating process more repeatable, Osterhout said. Automation leads to faster turnaround and lower labor costs. Automation also leads to tighter tolerances in the coatings. Average coatings may be somewhere between 0.0003 inch and 0.0008 inch, but with automation, Orion can reach down to ±3 microns thick.

“Our robotic technology ensures repeatability and high volume, giving our customers consistent coating over the entire part—from part to part, batch to batch, year after year,” Martucci said. “Our automated robotic coating applicators include a 7-axis cobot, and multiple 7-axis and 5-axis robotic coating cells.”

It isn’t all metal

Having 60 years of experience, Orion has bumped into some extremely odd requests. Orion’s coatings aren’t exclusively for rotors and aerospace parts. Sometimes people want something very unusual coated with a slippery surface, and in one case, that was car tires.

Both Osterhout and Yoder were shaking their heads as they remembered that one. A car company wanted to test tire control and handling in a wind tunnel after coating the tires with a Teflon-like coating. In earlier tests, the company used oil or water to simulate slippery conditions. But that created a mess inside the air tunnel, so they thought about finding a Teflon-type coating. Osterhout and Yoder said as unusual as it sounds, they’ve been asked to coat tires several times. In the testing, the coating will last about 30 minutes on a tire.

Both Osterhout and Yoder were shaking their heads as they remembered that one. A car company wanted to test tire control and handling in a wind tunnel after coating the tires with a Teflon-like coating. In earlier tests, the company used oil or water to simulate slippery conditions. But that created a mess inside the air tunnel, so they thought about finding a Teflon-type coating. Osterhout and Yoder said as unusual as it sounds, they’ve been asked to coat tires several times. In the testing, the coating will last about 30 minutes on a tire.

Orion Industries once worked on an auto shaft held in place by eight bearings. The steel shaft was running against an aluminum housing. By Teflon coating the shaft, the customer was able to remove the eight bearings. That reduced the assembly cost, as well as the number of bearings. An eight-bearing raceway was replaced by the Teflon coated shaft. Orion had to meet the internal diameter dimension exactly for the ring to make the seal, Osterhout said.

Another unusual coating job was of a silicone bag holding metal tools and parts that went into space. Yoder said the customer wanted to keep out oxygen. The customer settled on a PTFE-type coating, and Osterhout said that isn’t a typical use for the coating.

One particularly challenging aerospace part, still in production, is a stainless steel O-ring that is larger than a dime but smaller than a quarter. The ring had to be PTFE coated twice. About 100 of them are used in a single rocket engine, and the customer had been coating the part in-house, but not successfully.

One particularly challenging aerospace part, still in production, is a stainless steel O-ring that is larger than a dime but smaller than a quarter. The ring had to be PTFE coated twice. About 100 of them are used in a single rocket engine, and the customer had been coating the part in-house, but not successfully.

Orion went back and forth with the customer over time to resolve the challenges, such as how thick and how smooth the coating must be. The ring’s curved surfaces had to be coated, but no adjacent surfaces could be coated.

“We had to meet thickness requirements and smoothness requirements. We worked with them extensively to get it right,” Yoder said.

The work is ongoing. Orion would like to automate the coating process for this part to ensure coating precision and repeatability. “There are a lot of rockets going up,” he said. “Hundreds of this type of seal going up in an engine. You have to control the ID precisely.”

Lubricious Metal Coatings for Oil-free Air Compressor Rotors

Orion Industries coats metal and other materials to lower costs, improve materials performance, and—in some cases—improve air quality in manufacturing plants.

Orion coats aluminum and steel and other materials to help the metal perform in extreme conditions, such as the cold temperatures of space or the high heat and pressure of an engine. The coatings may make metal more lubricious or reduce galling, and therefore lead to longer life and less maintenance.

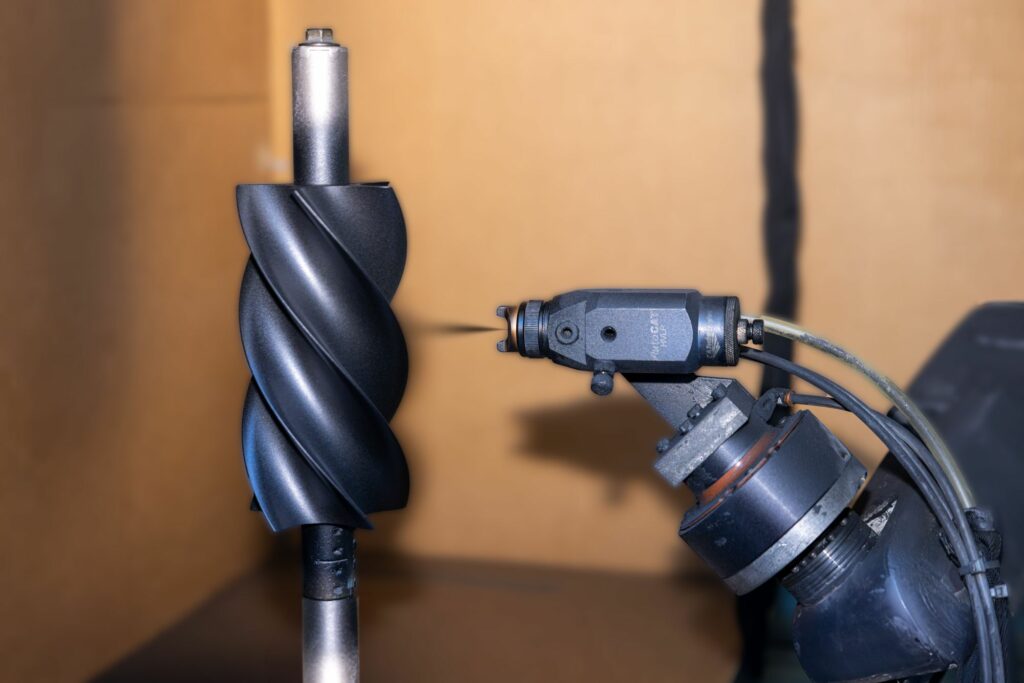

In oil-free air compressors, Orion coatings are used to improve performance by reducing maintenance and improving compression. Oil-free air compressors are used for that reason in electronics manufacturing plants, as well as in semiconductor, pharmaceutical, food processing, and other precision manufacturing plants where clean air is essential. That is in addition to Orion’s extensive aerospace and defense capabilities.

George Osterhout, Orion’s former president and now senior consultant, said the company’s coatings are designed to survive the heat and cold of outer space, as well as the routine heating up and expanding when used inside a factory, which is what happens in air compressors as the rotors spin to compress the air.

“You’re closing the gap by coating it. They’re rotating at 20,000 rpm,” said Osterhout. “They’re right next to each other. The coating improves the efficiency by 20 percent. The coating’s survivability depends on not touching. Our coating reduces the gap and any potential galling of the rotors. It will last a long time on the surface.

“It will withstand high heat. It will withstand frigid temperatures, minus 300 degrees. Unless there is wear, it will last a long time,” he added. He explained that before and after the parts are coated, they are checked to make sure they aren’t rubbing against each other.

Bruce Nesbitt, the motorsports enthusiast who founded Orion, started researching coatings to speed up cars. He’d read about these coatings after the 1963 Le Mans, when Porsche coated its racing car parts to help win the 24-hour race. Nesbitt kept researching for the next year and, after enlisting the help of friends, founded Orion (named after the Hunter) in 1964. His first goal? Coat race car parts.

Fast forward to 2025: Orion is AS9100D certified and ISO 9001:2015 certified, as well as ITAR registered. The AS9100D designation applies to quality management systems for aerospace and defense industries. The 9001 designation applies to repeatable quality manufacturing in all processes.

Orion applies high performance coatings for defense and aerospace that meet military specifications to protect the metal from extreme temperature while maintaining structure, abrasion resistance, and lubricity. Inside air compressors, rotors coated in oil spew oil into the compressed air, adding contaminants. Manufacturers or facilities that require contaminant free, clean air, turn to oil-free air compressors to manufacture electronics, semiconductors, pharmaceuticals, food, and other precision products. Orion provides coatings for oil-free air compressor rotors.

Orion coats its customers’ rotors with its proprietary DB L-908 coating at 0.002 to 0.008 inch, which is thick enough to lubricate the two rotors and conform to them while remaining bonded. No oil. No air contaminants. The film is compressed during manufacturing by one rotation of the rotors. Once compressed, the film lubricates the rotors and reduces friction as the rotors heat up and expand during operation. The coating has been tested and shown to improve efficiency anywhere from 5 percent to 20 percent.

“We’ve developed a proprietary coating technology called DB L-908, a conformable coating that minimizes air-gaps between high-speed mating surfaces, such as air compressor rotors. DB L-908 is applied in thicknesses from 0.002 to 0.008 inch with a tight tolerance of ±0.001 inch. Customers achieve a minimum of 5 percent increase in efficiency, along with a reduction in noise and a reduced output temperature of the air,” said Osterhout, who has more than 40 years of experience in the coating industry.

Orion coatings reduce the lash between two rotors, the clearance where air is lost, while compressing most of the air. Lash is also called play, slop, or backlash. The “conformable” coating fills the gap between the two rotors, reducing the lost air while protecting the two rotors from abrasion, corrosion, or galling.

—Mark Langlois