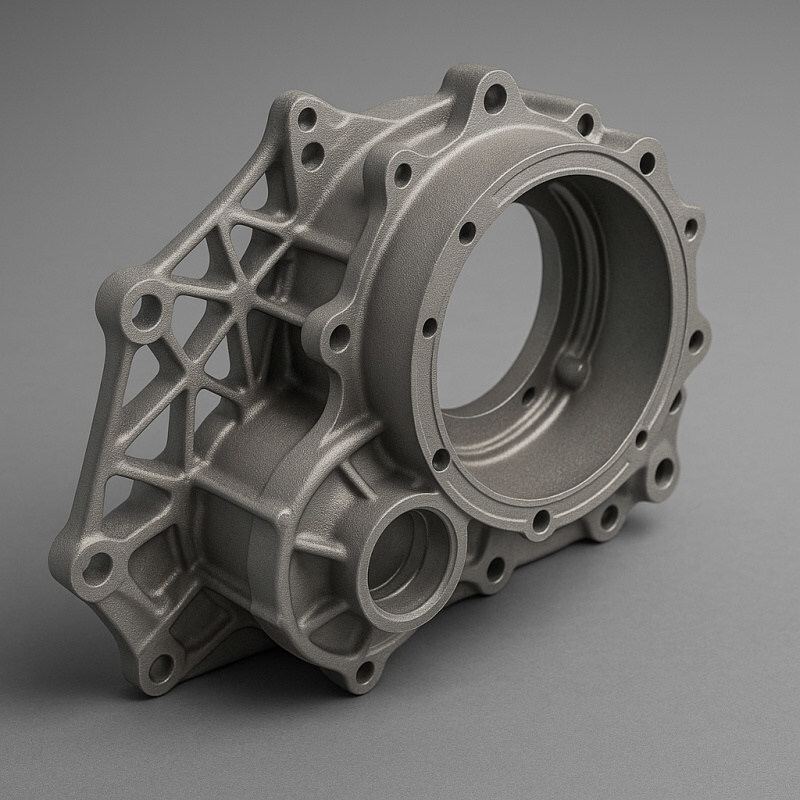

A concept rendering of a titanium gearbox housing, illustrating the types of parts under evaluation for Vittori’s additive manufacturing roadmap. (Image: Vittori/PRNewswire)

Vittori is working with Totum 3D and ShapeUp Studios to design, prototype, and manufacture the components in its ‘road-to-air’ plan for metal additive manufacturing.

PALO ALTO, Calif.—Vittori, a company that engineers and builds hyper-performance machines for land and sky, reported that it entered a production partnership with Totum 3D and ShapeUp Studios to design, prototype, and manufacture titanium 3D‑printed components.

The partnership is key to Vittori’s three-phase roadmap for incorporating additively manufactured parts in high-performance supercars (hypercars), followed by premium electric vertical-takeoff and landing (eVTOL) aircraft and electric‑jet programs. The scope of the partnership covers design‑for‑additive reviews, rapid prototyping, and pilot short‑run builds of 3D‑printed parts, according to a release from Vittori.

The teams are testing a practical mix of materials—titanium for strength‑to‑weight ratio; stainless and maraging steels for heavy loads; aluminum alloys for light structures; nickel superalloys for hot zones; copper alloy for cooling hardware; and aerospace polymers, such as PEEK and ULTEM, for cabin‑safe components. Examples of the materials currently being tested are reported to include 316L and 17‑4PH stainless, AlSi10Mg and Scalmalloy aluminum, Inconel 718, and CuCrZr.

For larger sections, the teams are pairing printed parts with carbon‑fiber panels and honeycomb cores. Any cabin‑facing materials will be qualified to meet aviation flame, smoke, and toxicity standards, Vittori said in the release.

Vittori’s approach focuses on production today with third‑party manufacturing, and a clear transfer path from road to air. The company’s AI-hybrid hypercar, the Vittori Turbio—featuring a V12 targeting about 1,100 horsepower and 3D-printed titanium components—is scheduled for unveiling on October 4 in collaboration with Pininfarina. The company is expected to share further details of the design at the live event.

“As others explore aerospace concepts, we’re putting titanium parts into production now,” said Carlos Cruz, founder of Vittori, in a statement. “Proving hardware on the road first lowers risk and speeds our move to the air. The same printed structures and thermal systems will migrate into our eVTOL and, later, our electric jet.”

“Vittori’s road‑to‑air plan is a strong fit for metal additive,” said Stefano Turconi, head of Totum 3D, in the release. “Common, lightweight architectures reduce part count and lead time while meeting demanding performance targets.”