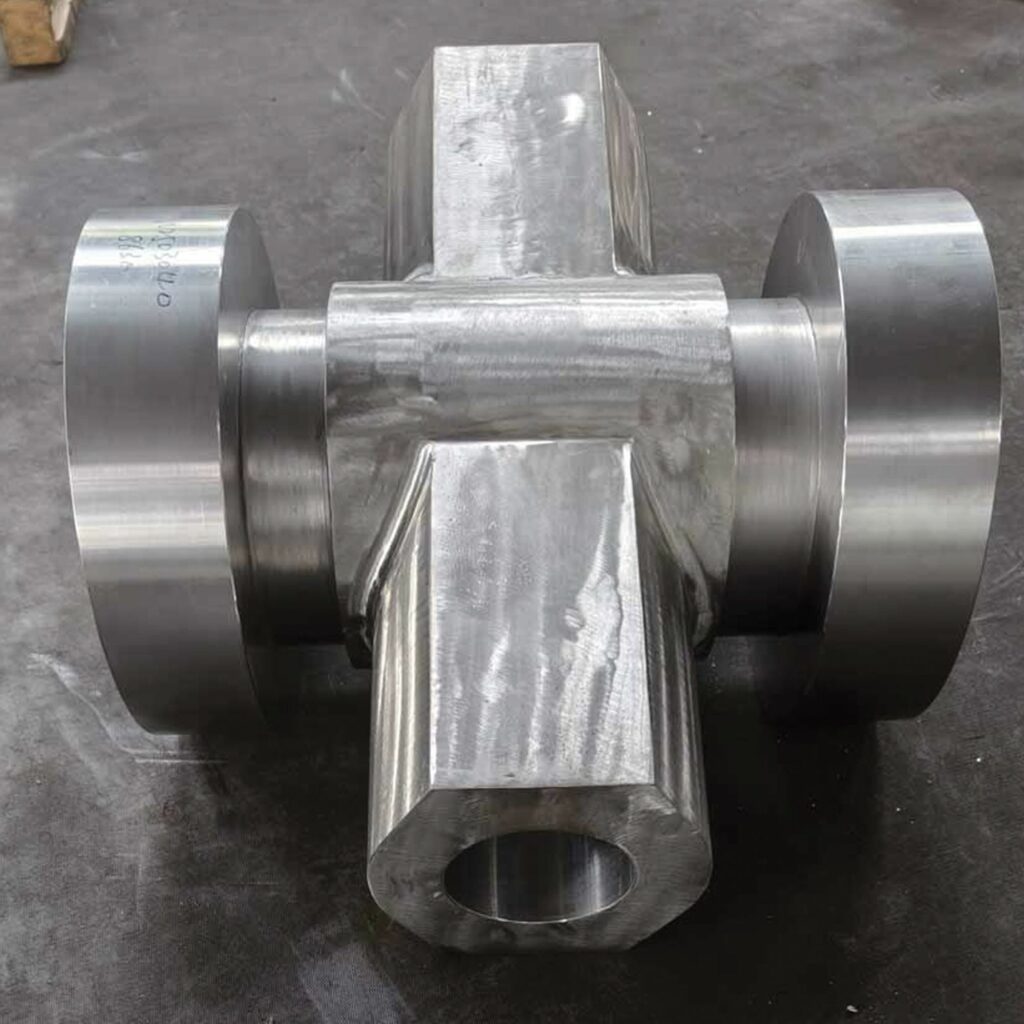

A near-net shape forged part manufactured by AMFG. (Photo: All Metals & Forge Group/EIN Presswire)

The approach reduces waste and allows for more uniform property development throughout critical sections of the final part, according to AMFG.

FAIRFIELD, N.J.—As manufacturers search for greater efficiency and durability from forged components, All Metals & Forge Group (AMFG) has responded to their call by enhancing its capability to produce precision, near net-shaped forgings that “support the demands of today’s most challenging applications.”

All Metals & Forge Group has long offered forgings as rough-machined parts. But the company went a step further recently by upgrading its equipment and process control to further optimize its ability to “provide near-net geometries with minimal waste and improved material performance,” AMFG stated in a release in advance of FabTech 2025.

A clear benefit of near net-shaped forgings, according to AMFG, is that they are unlike those that start from a large, forged block that must be heavily machined and then heat treated, often leading to inconsistent mechanical properties at depth.

Instead, near-net-shape forgings are forged to follow the outline of the final part as closely as possible with rough machining before heat treatment. This allows for more uniform property development throughout the critical sections of the final part, the company said.

The approach reportedly reduces machining time, tooling wear, and uncertainty in mechanical properties at depth from heat treatment.

“For engineers developing new products or optimizing existing designs, near-net-shape forgings offer a practical, high-performance solution,” the release stated. “As industry moves toward smarter, more sustainable manufacturing, these components are helping to unlock stronger, lighter, and more reliable parts.”

All Metals & Forge Group produces open die forgings and seamless rolled rings—rough, near net, or finish machined—for commercial and industrial uses in standard shapes or complex geometries. The company provides heat treating to modify mechanical properties for unique applications. Finish machining is available for ready-to-use parts, the company said.

Industries supported by AMFG include aerospace, defense, power generation, engine and turbine, food processing, gear making, machine building, and Tier-1, Tier-2, and Tier-3 machine shops. The company also serves customers in the oil and gas, pulp and paper, petroleum and chemicals, shipbuilding, transportation, and valve and pump markets.