Unlocking Ceramic 3D Printing for Next-Generation Chemical Reactors

By Tina Johnson

OAK RIDGE, Tenn.—In collaboration with chemical technology and engineering company Dimensional Energy, scientists at the U.S. Department of Energy’s Oak Ridge National Laboratory have integrated binder jet additive manufacturing with an advanced post-processing method to fabricate leak-tight ceramic components, overcoming a key challenge of ceramic additive manufacturing.

From left, Amy Elliott, Trevor Aguirre and Corson Cramer stand next to a tube furnace, which was used for heat-treating the materials used in this study. (Photo courtesy Amy Smotherman Burgess/ORNL, U.S. Dept. of Energy)

While ceramic components perform exceptionally well in extreme environments—exhibiting high temperature resistance, chemical stability, and mechanical strength—current methods of ceramic 3D printing fall short on scalability. This shortcoming limits their use in critical applications such as high-throughput chemical reactors, which are used for pharmaceutical or chemical processing, where large, leak-proof parts are essential.

Oak Ridge National Laboratory’s innovative solution provides a scalable method for creating complex ceramic structures by leveraging a robust joining technique that enables smaller 3D-printed pieces to be assembled to create the needed components.

“Ceramic 3D printing allows fabrication of intricate and high-performance components that are difficult to achieve with traditional manufacturing methods,” said researcher Trevor Aguirre, with ORNL’s Extreme Environment Materials Process Group. “This advancement provides a validated methodology to produce high-quality components—and enable the development of next-generation reactors.”

From left, Corson Cramer, Trevor Aguirre and Amy Elliott discuss the silicon carbide gyroid component, which was 3D-printed using the binder jet printer displayed in the background. (Photo courtesy ORNL, U.S. Dept. of Energy)

Oak Ridge National Laboratory partnered with Dimensional Energy—originator behind the innovative method—to perform a comprehensive case study. The team evaluated multiple design configurations to pinpoint optimal structures that inherently ensure gas-tight integrity. In addition, the team developed advanced post-processing techniques to improve the bonding and sealing of ceramic segments.

Not only does the innovation help meet the increasing demand for large-scale components, but it also leverages cost-efficient binder jet additive manufacturing, or BJAM, where powder layers are fused with a binder to create solid objects. This method offers substantial economic benefits and paves the way for broader industrial adoption of ceramic additive manufacturing in other high-performance applications such as aerospace, among others.

This is the first known leak-tight joint fabricated using additive manufacturing methods, paving the way for scalable BJAM assemblies.

The collaborative team received SME’s 2025 Dick Aubin Distinguished Paper Award for this research, which recognizes significant contributions to additive manufacturing. The team also has related research published in the Ceramics International journal.

“Dimensional Energy believes that ceramics have the potential to fill niche applications as components of a chemical refinery, with many properties vastly superior to metal alloys,” said lead PI Bradley Brennan, chief science officer for Dimensional Energy. “However, manufacturing of large and complex parts is a challenge, and sealing parts together to form a robust and leak-tight connection is equally difficult. Dr. Bhargavi Mummareddy, award-winning additive manufacturing expert at Dimensional Energy, was tasked with pushing the boundaries of what is possible, and she surpassed all our goals alongside the talented ORNL team.”

Researchers who contributed to this project include Trevor Aguirre, Dylan Richardson, Corson Cramer, Amy Elliott, and Kashif Nawaz from ORNL, along with Bhargavi Mummareddy, Franklin Milton, and Bradley Brennan from Dimensional Energy.

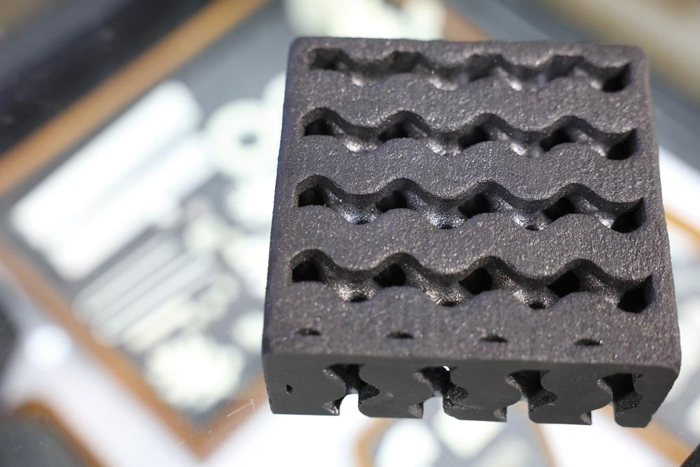

This component was 3D-printed, filled with a silicon-carbide pre-ceramic polymer and heat-treated to produce amorphous silicon carbide. (Photo courtesy Amy Smotherman Burgess/ORNL, U.S. Dept. of Energy)

The project was funded by DOE’s Advanced Research Projects Agency-Energy and by DOE’s Office of Energy Efficiency and Renewable Energy. The Manufacturing Demonstration Facility, where this work was conducted, is supported by DOE’s Advanced Materials and Manufacturing Technologies Office and acts as a nationwide consortium of collaborators focused on innovating, inspiring and catalyzing the transformation of U.S. manufacturing.

UT-Battelle manages ORNL for the DOE’s Office of Science, the single largest supporter of basic research in the physical sciences in the United States. The Office of Science is working to address some of the most pressing challenges of our time.

Tina Johnson is a writer for Oak Ridge National Laboratory.

Source:

https://www.ornl.gov/news/unlocking-ceramic-3d-printing-next-generation-chemical-reactors

Ceramics Industry Poised for Strong Growth, Estimated to Reach $62.5 Billion by 2030

BOSTON—The global ceramics industry is expected to grow from $41.3 billion in 2025 to $62.5 billion by the end of 2030, registering a compound annual growth rate (CAGR) of 8.6 percent during the forecast period of 2025 to 2030. That’s according to a report published by market research and data analysis firm BCC Research, which highlights results of a study analyzing the global ceramics market.

The report, Ceramics Markets: A BCC Research Outlook, is segmented by product type, end use, and region. It covers six key ceramic categories: technical ceramics, bioceramics, electroceramics, polymer-derived ceramics (PDCs), 3D-printed ceramics, and transparent ceramics. The report breaks down each category by material composition, application or end use, and regional distribution across North America, Europe, Asia-Pacific, South America, and the Middle East and Africa.

While the regions of Asia-Pacific, Europe, and North America are currently seen as the leaders in ceramics innovation, emerging markets are showing growing potential, BCC Research stated in a release outlining the findings of its report.

The BCC Research study is said to be “especially relevant now due to the accelerating global demand for ceramics driven by sustainability, miniaturization, and customization trends, particularly through 3D printing.”

“The study highlights the diverse applications of ceramics in industries such as electronics, energy, automotive, aerospace, medical, and defense. In doing so, it reflects the growing global demand for—and innovation in—advanced ceramic technologies,” the release stated.

Fueling that demand are next-generation technologies that are becoming increasingly dependent on advanced ceramics. Electric vehicles (EVs), for example, are boosting the use of advanced ceramics in batteries, power electronics, and lightweight components.

“Ceramic-based solid-state batteries are emerging as a breakthrough technology, offering higher energy density, improved safety, and longer lifespan compared to traditional lithium-ion batteries,” the release stated. “Companies such as Toyota and Samsung SDI are developing ceramic electrolytes to replace conventional liquid electrolytes, reducing the risk of thermal runaway and battery degradation.”

Meanwhile, 3D printing enables rapid prototyping and complex designs for medical and industrial applications. And transparent ceramics are expanding into photonics, military optics, and wearable technologies, marking what the report called “a pivotal moment for the industry.”

Factors Driving Growth of the Ceramics Market

Key factors that are driving the growing ceramics market include the use of bioceramics (biocompatible ceramics) in dental care; electroceramics in electronics; polymer-derived ceramics (PDCs) in aerospace and energy; and transparent ceramics in optolectronics. Also lifting the market: rising demand for technical ceramics in high-performance coatings, as well as greater use of bioceramics for regenerative medicine and tissue engineering, according to BCC Research.

Bioceramics are increasingly used in dental implants and restorations due to their safety, durability, and compatibility with human tissue. As overall awareness of dental health grows, especially among aging populations, demand for these materials continues to rise. In addition, electroceramics are playing a key role in miniaturizing consumer electronics like smartphones and wearables. Their unique electrical properties make them essential for compact, high-performance components, such as sensors and capacitors, according to the release.

Polymer-derived ceramics are valued in aerospace and energy for their ability to withstand extreme temperatures and harsh environments. This makes them ideal for aerospace, defense, and energy systems, where reliability under stress is critical. Transparent ceramics are used in lasers, lenses, and optical devices due to their clarity and strength. As optoelectronics and photonics expand in fields like communication and medical imaging, demand for these materials is growing rapidly, the release said.

“The global ceramics market is evolving through advanced materials engineered for durability, heat resistance, and specialized performance, driven by innovations in electroceramics, 3D printing, transparent ceramics, and sustainability across sectors like construction, electronics, healthcare, and defense,” the release stated.

The report identified two emerging startups that are playing key roles in the ceramics ecosystem: SINTX Technologies, Inc., and Bosch Business Innovations GmbH. SINTX Technologies, a specialist in advanced ceramic technology, produces technical ceramic and composite components for the biomedical, aerospace, defense, and energy markets.

Bosch Business Innovations (Bosch Advanced Ceramics) is an additive manufacturer of advanced ceramics that uses injection molding, as well as 3D printing processes. The company also serves as an engineering partner for sophisticated ceramic components, offering comprehensive consultation services from material selection to design optimization, the release said.

Source: BCC Research/Globe Newswire

U.S. FDA Grants 510(k) Clearance for Ceramic Based Foot-and-Ankle Implant System

The U.S.-manufactured implant system positions SINTX to enter a billion-dollar U.S. market, the company said.

SALT LAKE CITY, Utah—Advanced ceramics company SINTX Technologies, Inc., a specialist in biomedical applications of silicon nitride (Si₃N₄), received U.S. Food and Drug Administration (FDA) 510(k) clearance for its SINAPTIC® Foot & Ankle Osteotomy Wedge System in October, the company said in a release.

The clearance enables SINTX’s commercial entry into the market for reconstructive foot-and-ankle surgery in the United States. The company said it plans a U.S. commercial launch in the first quarter of 2026, “leveraging its U.S.-based manufacturing to drive revenue acceleration and operating efficiency.”

The SINAPTIC wedge system, manufactured with silicon nitride biomaterial, is engineered to deliver stable correction in foot and ankle osteotomy procedures. Its design is reported to offer precision fit, predictable technique, and compatibility with biologic augmentation, supporting surgical reproducibility and optimal bone healing.

“The SINAPTIC implant system combines SINTX’s proprietary silicon nitride biomaterial with surgeon-informed implant designs and a planned sterile, single-use instrument kit engineered to enhance surgical efficiency, precision, and reproducibility,” the release stated.

By combining differentiated material science with practical surgical innovation, the SINAPTIC implant system is said to exemplify SINTX’s strategy to “leverage its unique biomaterials platform into scalable, high-value medical solutions that address unmet clinical needs and drive long-term growth.”

“Orthopedics is evolving beyond traditional materials,” said SINTX Chief Commercial Officer Lisa Marie Del Re, in a statement. “With growing demand for non-metal solutions, the SINAPTIC system delivers the proven performance of silicon nitride to foot and ankle reconstruction—elevating expectations for surgical outcomes.”

Some of the material claims regarding SINTX’s silicon nitride ceramic that were cleared under the FDA submission, and which are relevant to the device, include the following properties:

- Pro-osteogenic: Unique surface chemistry mechanisms have demonstrated superior protein absorption and osteointegration when compared to traditional biomaterials.

- Bacteriostatic: Surface properties have been shown to actively repel and/or inhibit the growth of various types of bacteria in a laboratory and animal studies.

- Hydrophilic: Attracts fluids, further deterring bacteria colonization and enhancing bone-building mechanisms.

- Enhanced visibility on imaging: Unlike metal implants, silicon nitride allows for clear visualization of the surrounding tissues in X-rays and CT scans.

“FDA clearance of our SINAPTIC portfolio is a defining commercial milestone for the company,” said SINTX Chairman, President, and CEO Eric Olson, in a statement. “By entering the high-value, procedure-driven market with a differentiated biomaterial and surgeon-validated designs, we expect to generate meaningful clinical impact and build shareholder value as we execute our commercial strategy.”

According to SINTX, industry estimates pegged the global market for foot-and-ankle devices at approximately $4.75–$5.4 billion in 2024.

“While osteotomy wedges represent a subset of this category, SINTX believes procedure growth, ASC migration, and workflow-enhancing single-use instrumentation together create a compelling revenue opportunity,” the company stated in the release.

Located in Salt Lake City, SINTX Technologies is an advanced ceramics company that develops and commercializes materials, components, and technologies for medical and other high-value applications. The company describes itself as “a global leader in the research, development, and manufacturing of silicon nitride.”