How AI Is Unlocking Greater Operational Intelligence, from Predictive Maintenance to Quality Control

DUBLIN—A new report by market research firm Research and Markets states that manufacturers are rapidly adopting artificial intelligence (AI) technologies to streamline production workflows, enhance real-time decision making, and support predictive maintenance across diverse manufacturing operations.

The willingness of manufacturers to embrace AI reflects robust growth in the global market for AI technologies in manufacturing, according to a release from Research and Markets summarizing the findings of its report.

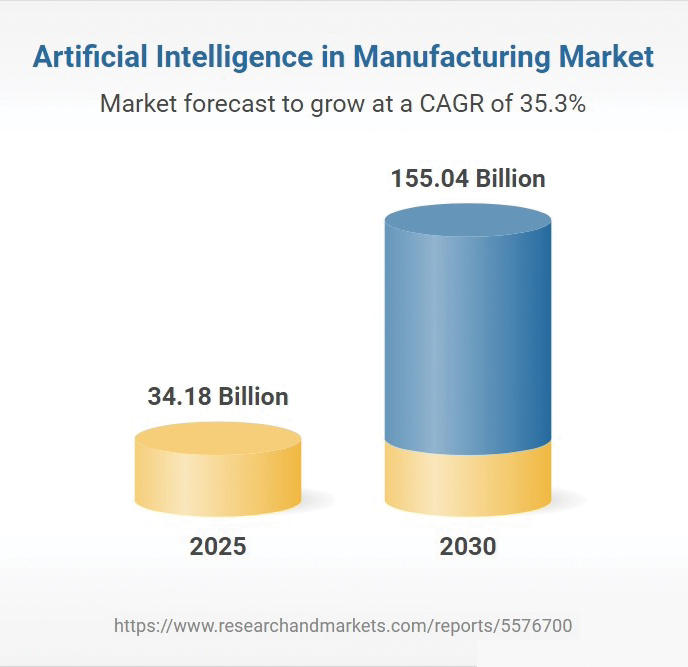

The report, “Artificial Intelligence in Manufacturing Market,” anticipates the global market for AI in manufacturing will increase from $34.18 billion in 2025 to $155.04 billion by 2030 (in U.S. dollars). The market is expected to record a compound annual growth rate (CAGR) of 35.3 percent during that period, Research and Markets stated in the release.

The global market for AI in manufacturing is projected to jump from $34.18 billion in 2025 to $155.04 billion by 2030 (in U.S. dollars), more than quadrupling its value during the forecast period. (Image courtesy Research and Markets)

“As manufacturers strive for greater agility, cost efficiency, and quality assurance, AI solutions are becoming instrumental in unlocking new levels of operational intelligence and productivity,” the release stated. “Industries such as automotive, electronics, aerospace, and consumer goods are employing machine learning, computer vision, and natural language processing to optimize production scheduling, reduce downtime, and detect anomalies early in the process. The use of AI-enabled robots, digital twins, and intelligent quality control systems allows manufacturers to scale output with precision and adaptability.”

Moreover, the integration of AI with industrial IoT platforms and cloud-based data analytics is said to accelerate the transition to smart factories by enabling connected, data-driven ecosystems.

“With growing emphasis on sustainability, customization, and global competitiveness, AI is set to play a transformative role in shaping next-generation manufacturing paradigms. As the demand for intelligent automation and continuous process innovation intensifies, the AI in manufacturing market is poised for sustained expansion across all regions and industry verticals,” the company said in the release.

By application, predictive maintenance held largest market share in 2024

In 2024, the predictive maintenance segment emerged as the leading application in the market for AI in manufacturing. The development was driven by the growing emphasis on minimizing equipment failures, reducing operational downtime, and optimizing asset performance, the company said.

“Manufacturers across industries increasingly adopted AI-powered predictive maintenance systems to analyze sensor data, detect anomalies, and forecast equipment failures before they occurred. This approach enabled timely and targeted interventions, helping companies avoid costly disruptions and improve overall production efficiency,” the release stated.

Key sectors such as automotive, heavy machinery, and energy and power—as well as semiconductor and electronics manufacturing—prioritized predictive maintenance. This was especially true in high-volume and capital-intensive operations, where unplanned outages could result in significant losses.

Artificial intelligence algorithms, integrated with IoT and cloud platforms, enabled real-time condition monitoring and intelligent diagnostics. This offered a clear advantage over traditional reactive or time-based maintenance models.

“The widespread use of AI-driven insights to anticipate failures, optimize maintenance schedules, and reduce spare part wastage contributed significantly to the segment’s dominance,” the company said. “Additionally, the return on investment from predictive maintenance through improved equipment uptime, extended asset life, and reduced labor costs made it a strategic priority for manufacturers. As factories continued to evolve toward smarter, data-centric operations, predictive maintenance firmly held its position as the most impactful AI application in the manufacturing sector in 2024.”

By technology, machine learning held largest market share

Among technologies, the machine learning segment represented the largest share of the market for AI in manufacturing in 2024. This is said to reflect the central role of machine learning in enabling data-driven decision making, process optimization, and adaptive automation across the industry.

“Manufacturers increasingly relied on machine learning algorithms to analyze large volumes of operational data generated by sensors, machines, and enterprise systems, uncovering patterns and trends that traditional methods could not detect,” the release stated. “This allowed companies to enhance production efficiency, improve quality control, and respond swiftly to changing market demands.”

According to the release, industries such as automotive, electronics, metal manufacturing, and heavy machinery manufacturing have adopted machine learning to drive applications ranging from demand forecasting and predictive maintenance to anomaly detection and process optimization.

The ability to continuously learn and refine models based on real-time data is reported to have made machine learning especially valuable in dynamic environments with complex operations and high variability. The integration of machine learning with industrial IoT platforms, cloud computing, and edge devices significantly expanded its use across both discrete and process manufacturing.

“The ability to automate decision-making, reduce human error, and uncover hidden inefficiencies reinforced machine learning’s dominance as a foundational AI technology. As manufacturers pursued greater agility, scalability, and competitiveness, machine learning emerged as the most widely implemented and impactful technology within the AI in manufacturing landscape,” the release stated.

Europe is projected to record significant growth

Going forward, Europe is expected to show significant growth in the AI in manufacturing market, supported by what the release described as “a strong focus on industrial modernization, digital innovation, and automation-led competitiveness.”

“Manufacturers will continue to embrace AI technologies to improve productivity, reduce operational inefficiencies, and meet evolving regulatory and sustainability standards,” the release said. “Government-led initiatives across various European nations have played a significant role in accelerating AI integration within the manufacturing sector. Investments in research and development, along with supportive policies for smart factory development, have created a favorable environment for AI adoption.”

The presence of a highly skilled workforce, advanced industrial infrastructure, and well-established digital ecosystems have reportedly enabled faster deployment of AI across the region. European manufacturers are increasingly leveraging AI to enhance production intelligence, implement real-time monitoring, and support autonomous decision-making. The emphasis on quality, precision, and traceability has further driven the demand for AI technologies that enable continuous improvement and adaptive control, according to the release.

“As the region balances the goals of industrial innovation and environmental responsibility, AI adoption is expected to remain a key enabler of its manufacturing transformation, reinforcing Europe’s position as a major contributor to the global AI in manufacturing market,” the release stated.

Among the U.S. companies profiled in the report are NVIDIA Corporation, IBM, Intel Corporation, GE Vernova, Micron Technology, Inc., Rockwell Automation, Honeywell International Inc., Cisco Systems, Inc., and Hewlett Packard Enterprise Development LP. Also profiled are Sight Machine, Progress Software Corporation, Aquant, Bright Machines, Inc., Avathon, Inc., and Zebra Technologies Corp.

Independent Research Firm Verdantix Recognizes Augury as Leader in Industrial AI Analytics

Verdantix cited strong predictive maintenance capabilities, supported by a broad range of AI/machine learning techniques, as a key differentiator of Augury’s platform.

NEW YORK—Augury, an Industrial AI technology company focused on asset reliability and process optimization, reported in October that it was recognized by independent research and advisory firm Verdantix for its capabilities in industrial AI analytics.

In its inaugural Green Quadrant: Industrial AI Analytics Software (2025) report, Verdantix tabbed Augury as a Green Quadrant Leader in Industrial AI Analytics Software. The new Green Quadrant study is said to “validate Augury’s solutions for manufacturers facing unprecedented operational pressures.”

“The independent research validates Augury’s position as a leader delivering AI-focused industrial analytics solutions that help manufacturers overcome mounting economic pressures, supply chain uncertainty, and rising energy costs,” according to a joint release by Augury and Verdantix.

Augury said it uses purpose-built AI technology, trained by industry experts and what it called “the world’s largest data library,” to help manufacturing and industrial companies eliminate production downtime, improve process efficiency, maximize yield, and reduce waste and emissions. The company is the developer of industrial AI analytics technologies that include Machine Health, Process Health, and Production Health.

The Verdantix study comes at a critical time in which industrial companies are facing widening skills gaps amid aging workforces, fragmented data architectures, and a shortage of AI expertise. According to Verdantix’s report, “Market Size and Forecast: Industrial AI Analytics 2022-2028 (Global),” buyers are increasingly turning to AI analytics to unlock greater value from operational data. Spending on AI analytics is projected to reach $5 billion by 2028, according to the release.

“Augury scored 2.6/3.0 for predictive maintenance, the joint second-highest amongst all vendors,” the report states. “Its platform applies a broad range of AI/machine learning (ML) techniques, [and their] expert-in-the-loop approach provides additional transparency and accuracy, allowing users to understand outputs within the context of asset status and fault indications with confidence.”

The report highlights three key differentiators that are said to position Augury as a leader in Industrial AI analytics:

Strong Predictive Maintenance Capabilities: Augury’s platform delivers real-time diagnostics and continuous feature extraction, with models tuned by asset class and refined through expert feedback.

Performance Guarantees: Through its proprietary wireless sensors and Guaranteed Diagnostics™ program, Augury offers downtime compensation in the event of undetected machine health events for covered assets.

Comprehensive Multi-Modal AI Analytics Platform: The solution integrates industrial internet of things (IIoT) hardware with industrial AI analytics, applying advanced techniques such as anomaly detection, severity analysis, predictive analytics, and generative AI to multi-modal sensor and operational data for real-time diagnostics.

“Volatility is no longer the exception; it’s the new baseline with manufacturers constantly navigating supply chain strains, energy volatility, and growing talent shortages,” said Saar Yoskovitz, CEO and co-founder at Augury, in a statement. “We have a long track record of partnering with global manufacturers to build agility and ease their operational pressures, and Verdantix’s designation of Augury as a market leader is further validation of our ability to unlock greater value from production with AI.”

The recognition from Verdantix is said to position Augury at the forefront of an industry transformation, where traditional maintenance approaches are giving way to predictive, AI-driven strategies.

“As manufacturers seek partners who can deliver both technological innovation and measurable business outcomes, Augury’s designation as a leader reflects its unique combination of hardware expertise, advanced analytics, and performance guarantees that drive real operational impact,” the release stated.