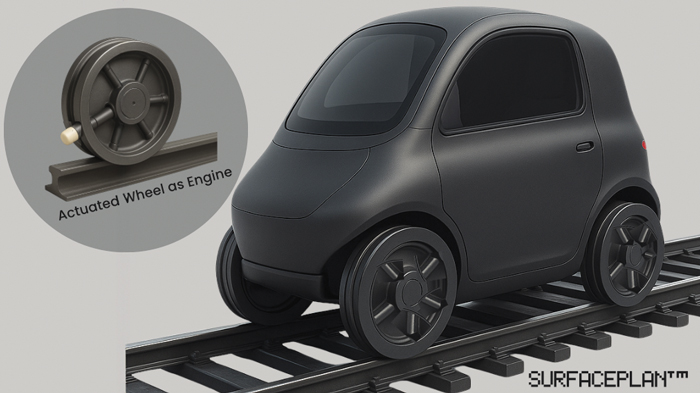

Actuators at the road surface. The SurfacePlan system uses precision actuators to deliver thrust exactly when and where traction is optimal. (Image courtesy David Henson/Surface Plan/EINPresswire)

SurfacePlan recently issued a global RFP for a reinvented wheel that uses embedded actuators to power itself without a drivetrain.

DENVER—Inventor David Henson envisions a new automotive design that transforms a car’s wheel into an engine, opening up a new world of fewer moving parts, programmable tire treads, lighter vehicles, improved traction, and fundamentally new ways to control motion.

Henson’s SurfacePlan™ design replaces traditional mechanical linkages with an array of precision actuators embedded at the tire surface, delivering force directly into the pavement.

“Why move a piston to move a shaft to move a gear to turn a wheel, when you can apply the thrust exactly where it’s needed?” Henson said in a September release introducing his design.

The surface-gripping actuators are said to extend and retract in precise sequence to push against road or rail surfaces, eliminating the need for separate propulsion components. Henson likens the concept to a moving “pin art” display, where hundreds of small pins move independently to create shapes.

“Now imagine those pins as actuators at the tire surface, each applying thrust directly into the road,” he said.

According to Henson, the system uses precision actuators powered by electric, hydraulic, or pneumatic means, synchronized by AI-assisted software to deliver thrust exactly when and where traction is optimal. By eliminating engines, transmissions, and drive shafts, vehicles can achieve dramatic weight reductions while improving energy efficiency.

Inventor David Henson’s SurfacePlan Wheel Concept. (Image courtesy David Henson/Surface Plan/EINPresswire)

The SurfacePlan system is detailed in a comprehensive provisional patent filing by Henson. It is reported to address key engineering challenges, including power delivery, durability, and high-speed stability, through innovations like directional stabilizing elements for maintaining optimal ground contact.

Open research questions are reported to include actuator durability, energy efficiency versus rotational systems, surface wear patterns, and control system complexity. SurfacePlan is seeking engineering and research partners to help evaluate and prototype these systems.

Preliminary analysis suggests the system could reduce vehicle weight by 50-to-75 percent while improving energy efficiency through direct force application, eliminating the conversion losses inherent in traditional drivetrain systems, according to the release.

The technology is said to go beyond incremental improvement by enabling entirely new vehicle architectures. Lightweight, single-person pods could link together for group travel, creating shared interior space when connected but maintaining individual efficiency when solo.

“This could live at Tesla, GM, Ford, Rivian, Toyota, or Volkswagen,” Henson said. “It could be advanced by an engineering school willing to share in the IP, or maybe Apple Computer wants to make the iWheel. But I’m not an insider in the auto or EV world. I’m just the guy with the idea, a provisional patent, and a clock ticking.”

SurfacePlan is also considering potential applications beyond traditional vehicles. For example, the SurfacePlan Wheel may enable low-cost ultralight rail systems that share wheels with street operation. The idea reportedly has attracted interest from urban transportation planners seeking flexible, infrastructure-light transit solutions. The company is also said to be exploring modular electric vehicle applications, where reduced vehicle mass could dramatically lower battery requirements.

The inventor has launched a WeFunder poll to gauge investor and public interest in “reinventing the wheel.”

With less than a year remaining on provisional patent protection, Henson is seeking strategic partners ready to prototype and commercialize what he called “breakthrough mobility technology.”

SurfacePlan is dedicated to reinventing the wheel as a simplified, actuated propulsion system. The result could enable ultra-light personal transport pods, modular rail systems, and next-generation robotics platforms. (Image courtesy David Henson/Surface Plan/EINPresswire)

He said potential partners include automakers looking for competitive advantage in EV efficiency and control; technology companies ready to make a design leap, not just an incremental step; or universities with robotics or mechanical engineering programs seeking breakthrough research projects. Venture capital groups specializing in transformative, high-risk, high-reward technologies might also be interested.

“Forget knocking on doors,” Henson said. “Somewhere among readers is the right person to recognize that this isn’t incremental improvement, it’s transportation reimagined from the ground up.”

SurfacePlan™ is a mobility innovation project founded by Henson in Pagosa Springs, Colorado. Its mission: Reinvent the wheel as an actuated propulsion system, unlocking lightweight, efficient, and flexible transportation across roads, rails, and beyond. The company’s research focuses on intelligent wheel technology, modular vehicle architectures, and lightweight composite structures designed for direct-thrust mobility.

In an October release, SurfacePlan reported that it issued a formal request for proposals (RFP) to actuator manufacturers worldwide. The company is seeking partners capable of producing high-duty-cycle linear actuators, rated for extended operation under continuous load.

The RFP targets suppliers with expertise in aerospace-grade actuation, high-frequency mechatronics, and advanced materials. Interested manufacturers can review technical specifications and partnership opportunities at SurfacePlan.com.

Henson presented his concept to an AI system that projected a market demand for 100 million actuators, the release stated.

“We’re at the prototype stage, but the interest has been significant,” Henson said in the release. “The AI simply recognized what we already knew: If you can put 18 actuators in each wheel and eliminate 60 percent of a vehicle’s weight, the addressable market becomes enormous—automotive, rail, robotics, aerospace. The applications stack up quickly.”

SurfacePlan currently holds four patents pending covering the actuated wheel system and related propulsion architectures.