Automotive lightweighting: replacing heavy metal with plastic. (Image courtesy Tesla Mechanical Designs/EINPresswire)

Tesla Mechanical Designs leverages advanced FEA and CFD services to empower OEMs to replace metal with high-performance polymers that enhance EV range and fuel efficiency.

EDISON, N.J.—As the automotive industry strives to meet fundamental efficiency goals for electric vehicles (EVs) and internal combustion engine (ICE) vehicles, Tesla Mechanical Designs is actively taking on “a critical role in the lightweighting revolution,” the company said in a release.

According to the company, its team is “leveraging its advanced product design services and simulation expertise to help OEMs and Tier-1 suppliers confidently replace heavy metal components with high-performance, injection-molded plastics.”

“By using finite element analysis (FEA) to validate structural integrity and CFD (computational fluid dynamics) services to manage thermal loads, Tesla Mechanical Designs is enabling the creation of lighter, more efficient vehicles without compromising on safety or performance,” the company stated in the release.

Driven by the need for longer EV battery range and stricter emissions standards, the pressure for efficiency has made lightweighting a top industry priority. Although advanced polymers offer a solution, they introduce significant engineering complexities, the company said.

Automotive components are subjected to extreme conditions, including constant vibration, high-impact forces (crash scenarios), and fluctuating temperatures from powertrains or battery systems. However, simply substituting plastic for metal is not an option.

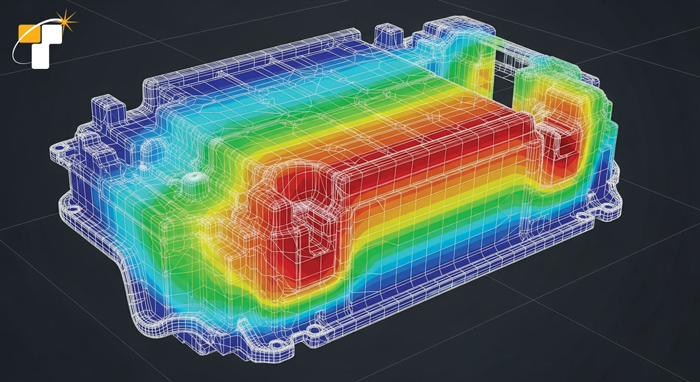

Finite element analysis (FEA) simulation validates a plastic part’s thermal performance. (Image courtesy Tesla Mechanical Designs/EINPresswire)

A successful transition, according to the company, requires “a sophisticated ‘simulation-first’ approach to validate a component’s performance under all possible load cases.”

“Replacing metal with plastic isn’t just a swap; it’s a complex engineering challenge,” said Tesla Mechanical Designs Director Kuldeep Gajjar, in the release. “We use advanced simulation to de-risk this process for our auto clients.”

Virtual testing: the key to de-risking innovation

Tesla Mechanical Designs said it acts as a virtual proving ground by allowing its clients to test and iterate on designs digitally before committing to multi-million dollar tooling investments. This process is built on two core simulation technologies:

Structural and safety validation with FEA: Finite element analysis services are essential for validating plastic components. Engineers simulate real-world forces to ensure part-level and assembly-level integrity. This includes conducting structural analysis for components, such as plastic-metal hybrid chassis parts, battery enclosures, and interior support structures, to confirm they meet and exceed rigorous OEM safety and durability standards.

Thermal and fluid dynamics with CFD: In electric vehicles, plastic battery enclosures must be lightweight but also integral to thermal management. By using computational fluid dynamics, engineers can simulate heat dissipation and fluid flow within these complex assemblies, ensuring battery packs operate at optimal temperatures for safety and longevity. This same analysis is applied to under-hood components in traditional engines, optimizing airflow and protecting sensitive parts, the company said.

From simulation to production-ready part

Services provided by Tesla Mechanical Designs extend beyond simulation. The company also provides a complete product development workflow that translates these validated digital concepts into tangible, manufacturable parts. This integrated process includes mechanical 3D modeling, mold-flow analysis, and precision documentation.

In mechanical 3D modeling, the Tesla Mechanical Designs team creates highly detailed, complex part geometries that are optimized for both performance and the injection-molding process. Mold-flow analysis, by which the team simulates the plastic injection molding process itself, is part of the firm’s component engineering expertise. The team uses this analysis to predict potential manufacturing defects, such as weld lines or warping, allowing for design corrections that ensure a high-yield, high-quality production run.

Finally, the team produces all necessary mechanical drawings and CAD drafting documentation, providing a “perfect, production-ready blueprint for toolmakers and manufacturers” (precision documentation), the company said.

“By providing this end-to-end expertise, Tesla Mechanical Designs is not just a design provider, but a critical partner helping the automotive industry build the lighter, faster, and more efficient vehicles of the future,” the release stated.

Source: EINPresswire.com