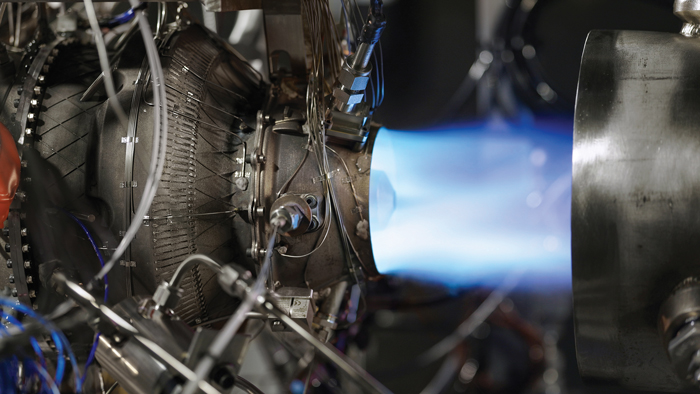

The Air Force Research Laboratory (AFRL) control room during high-altitude testing of Beehive’s Frenzy engine. (Photo courtesy Beehive Industries)

By completing high-altitude testing of its new metal 3D-printed jet engine, Beehive Industries validated its ‘additive-first’ manufacturing approach that enables it to compress traditional aerospace development cycles from years to months.

DENVER—Beehive Industries, an American manufacturer of advanced propulsion systems, specializes in design and development of jet engines for uncrewed aerial defense applications, as well as parts manufacturing across high technology industries. The U.S.-based company employs more than 300 team members and is “committed to powering American defense through advanced manufacturing and innovative offerings,” according to a December release from Beehive Industries.

Beehive announced in the release that it successfully completed high-altitude testing of its 200 lbf Frenzy™ engine. The Frenzy engine family, enabled by metal 3D printing for rapid production, spans 100 to 300 lbf in thrust. It is “designed to power next-generation uncrewed aerial systems (UAS) with unmatched efficiency, reliability, and affordability,” according to Beehive.

Prior to high-altitude testing, Beehive conducted a rapid development process, moving from finalization of production requirements to First Engine to Test (FETT) in five months. (Photo: Business Wire)

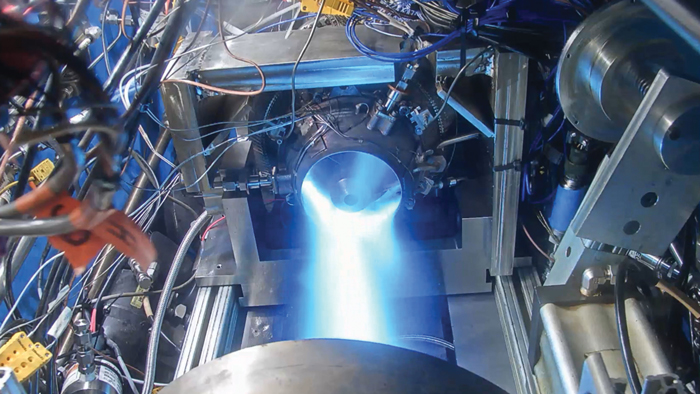

The company said a rigorous vacuum chamber test campaign confirmed successful engine ignition capability and performance at high altitude. By completing the test successfully, Beehive reported it achieved “another major milestone in the company’s rapid development program and confirming readiness for flight testing in the first quarter of 2026.”

“The achievement underscores Beehive’s ability to deliver cutting-edge propulsion to the warfighter at the speed of need—advancing American defense with innovation built for operational advantage,” the release stated.

The high-altitude test campaign, conducted at a government test facility in Ohio, is said to validate Frenzy’s performance and capability across the full flight envelope. Beehive has completed altitude testing on schedule and is now preparing to scale production to meet surging customer demand, the company said in the release

David Kimball, chief technology officer at Beehive Industries, said in a statement that the milestone confirms Frenzy’s readiness for flight integration.

“In less than a year, we’ve gone from concept to proven high-altitude performance—and we’re doing it ahead of schedule because of the talented and determined team at Beehive. Frenzy is now flight-ready, and our production system is ready to scale alongside it.”

The company said the altitude campaign capped “an extraordinary year of progress for Beehive’s Frenzy program.” Following the company’s September announcement of successful ground testing on four engines in six months, Beehive shipped—on schedule in October—two prototype engines to a government testing facility in Ohio for a series of high-altitude tests.

According to Beehive, the results—performance, ignition at altitude, operability, and durability —all met or exceeded challenging Air Force requirements. In doing so, they validated the disruptive capability of the Frenzy engine.

During the test campaign, the Frenzy engines are reported to have demonstrated the following results:

- Successful ignition and operation across the flight envelope

- Rapid acceleration from light-off to 100 percent engine speed

- Turbine temperatures and thrust-specific fuel consumption better than predicted

- “Like new” hardware condition after mission-life equivalent run time

Beehive said the results validate its additive-first manufacturing approach, which enables the company to “compress traditional aerospace development cycles from years to months while delivering disruptive cost and performance at unmatched scale.”

“This test campaign not only demonstrates the full potential of our engine, but also how we move with speed through a highly iterative, cross-functional development program,” Kimball added. “Each milestone strengthens our confidence in the architecture, our ability to deliver on our commitments, and the disruptive path we’re charting for next-generation propulsion. We’re not just accelerating development timelines—we’re ensuring America’s warfighters have the technology they need, when they need it most.”

Flight testing is set for early 2026. In the meantime, Beehive is preparing to integrate the Frenzy engine with its first flight vehicle—the final step before entering low-rate initial production. The company’s facilities in Denver, Cincinnati, and Knoxville are already ramping capacity to meet anticipated production demand, the release said.

The milestones Beehive achieved with its Frenzy engine are “extraordinary,” the company said, and are built on a $12.46 million U.S. Air Force Rapid Sustainment Office (RSO) / University of Dayton Research Institute (UDRI) contract awarded in October 2024, as well as the engine’s formal introduction in December 2024.

The University of Dayton Research Institute is a leader in research, development, and technology transition, partnering with organizations like Beehive and the U.S. Air Force to drive innovation in aerospace and propulsion. The Air Force Rapid Sustainment Office (RSO), a Division of the Air Force Life Cycle Management Center Combat Readiness Directorate, works to accelerate game-changing capabilities that sustain a modern Air Force.

“By exploiting new and emerging technologies, the RSO delivers sustainment and maintenance solutions at the speed of need to maximize warfighter readiness,” the release said.

Beehive Industries’ flight-ready Frenzy™ engine is pictured firing successfully during vacuum chamber testing in Ohio. Flight tests are slated for early 2026. (Photo courtesy Beehive Industries/Business Wire)

Prior to conducting high-altitude testing, Beehive carried out an accelerated development process, moving from the finalization of production requirements to First Engine to Test (FETT) in five months. The company then tested a new engine every six weeks, successfully completing ground testing on four Frenzy engines in a span of six months. According to Beehive, this rapid pace of development demonstrates the power of its additively-enabled manufacturing approach.

“This unprecedented speed highlights Beehive’s ability to compress traditional development timelines from years to months, a feat made possible by its innovative design and production techniques,” the release stated.

The testing program, conducted across Beehive’s Denver, Cincinnati, and Knoxville facilities, adhered strictly to the original program plan, as all four engines began testing on schedule. This consistency is said to underscore “the company’s reliable say/do culture and its commitment to delivering results.”

“Beehive’s rapid advancement with the Frenzy engine family is a testament to our team’s expertise and the transformative potential of additive manufacturing,” said Gordie Follin, chief product officer at Beehive Industries, in a statement. “These test results exceed our expectations and reinforce our mission to provide the U.S. military with affordable, high-performance propulsion systems that can be deployed at scale.”

The Frenzy engines, ranging from five to eight inches in diameter, successfully completed a comprehensive testing regimen that included performance and operability validation, durability validation, and environmental stress testing. Each engine is reported to have individually surpassed better-than-target power, better-than-target Specific Fuel Consumption (SFC), and more than a full mission of operational durability, while collectively accumulating more than 20 hours of runtime.

These results are said to not only validate Beehive’s bold performance claims but also position the Frenzy engine as “a game-changer for UAV (unmanned aerial vehicle) applications, where cost, efficiency, and reliability are critical.”

“Beehive’s rapid advancement with the Frenzy engine family is a testament to our team’s expertise and the transformative potential of additive manufacturing,” said Gordie Follin, chief product officer at Beehive Industries, in a statement. “These test results exceed our expectations and reinforce our mission to provide the U.S. military with affordable, high-performance propulsion systems that can be deployed at scale. We’re proud to collaborate with UDRI and the U.S. Air Force to push the boundaries of aerospace innovation.”

Sources: Beehive Industries, Business Wire