In America, the Dawn of Physical AI for Manufacturing

AI and machine learning platforms are making robots smarter and more capable, enabling U.S. manufacturers to address longstanding critical challenges.

By Mark Shortt

Physical AI for welding is creating new possibilities for metal fabricators at a critical moment for American manufacturing.

Last September, an enterprising U.S. developer of AI-powered autonomous welding technology launched what it called “the first purpose-built foundational AI model for welding.” The company, Columbus, Ohio-based Path Robotics, believes that its Obsidian™ AI model represents a fundamental shift in how robotic welding systems work.

Reportedly trained on “tens of millions of welded inches,” Obsidian is said to scan every seam, plan the weld in real time, and adjust as conditions change, eliminating the need for frequent reprogramming of the robot.

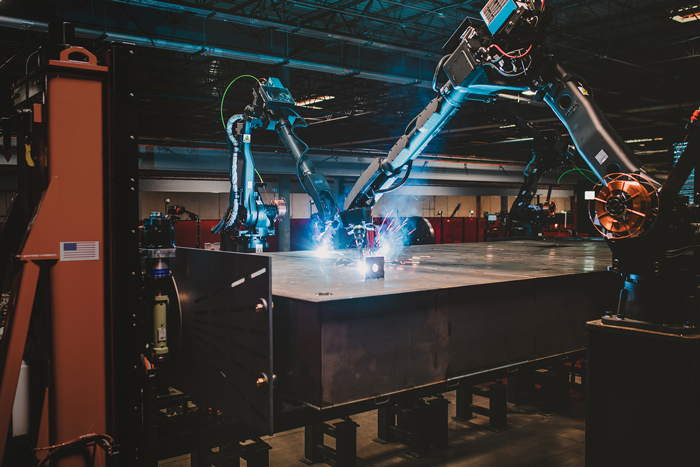

A Path Robotics intelligent welding cell in action. (Photo courtesy Path Robotics)

“Instead of requiring precise programming for every part, it learns and adapts—making autonomous welding possible for high-mix, low-volume manufacturers who’ve never been able to automate before,” the company said in the release accompanying the roll out.

Obsidian represents Physical AI for Welding—”a breakthrough that brings true machine intelligence to metal fabrication at a critical moment for American manufacturing,” according to Path.

“More than 60 years after the first industrial robot went to work on a factory floor, 80 percent of welding is still done manually,” the release stated. “The American Welding Society projects the U.S. will need 320,500 new welding professionals by 2029—approximately 80,000 jobs to be filled annually—from a labor pool that simply does not exist.”

Traditional robotic welding technologies haven’t been able to close this gap, Path believes, because real-world parts aren’t perfect. “Fit-up varies, joints wander, and heat distorts large weldments. Traditional automation excels at consistency but cannot adapt to the messy reality of most manufacturing environments.”

To overcome this challenge, Obsidian uses a proprietary vision system to scan every welding seam using lasers and optics. The data is then fed to Obsidian to develop the weld and path plan in real time. When welding begins, the system monitors the weld pool and seam to compensate for heat distortion as the weld progresses, the company said.

“The result is consistent weld quality without the traditional burden of fixturing parts to perfection, or reprogramming every time the part changes,” the release stated. “In simple terms: Obsidian is the autonomy layer; the robot arm is the actuator. Obsidian decides what to weld, where to weld, and how to weld—then generates and adjusts robot motion as conditions change.”

Since its founding in 2018, Path Robotics has reportedly raised more than $300 million to incorporate intelligence—through physical AI—into legacy manufacturing processes. Why not buck tradition by turning difficult work—which had long resisted efforts to automate it—into reliable, high-throughput, and high-quality production?

Path Robotics introduced Obsidian while demonstrating its capabilities in Chicago last summer at FABTECH 2025, North America’s largest metal forming, fabricating, welding, and finishing event. At the event, company representatives provided live demonstrations of Obsidian-powered welding systems handling the types of real-world variations and complexities that welders typically encounter, such as high-mix production, multi-pass welding, and imperfect parts.

“Path’s intelligent welding cells perform the complex, variable welds that traditional automation cannot, enabling manufacturers to overcome chronic labor shortages while increasing production capacity, and improving quality,” the company said.

Now, by combining artificial intelligence, machine learning, and computer vision, Path Robotics’ physical AI is said to enable legacy manufacturing processes to see, think, and adapt in real time, turning what had been impossible for traditional welding processes into a reality.

Shipbuilder Is Partnering with Path Robotics to Transform Barge Manufacturing with Physical AI for Welding

LAD Services, a shipbuilder in Morgan City, Louisiana, announced in December that it is partnering with Path Robotics to bring Path’s Physical AI for welding into its shipbuilding operations.

By investing in Path’s technology, LAD is hoping to surmount what has become an all-too-common obstacle: the widespread shortage of skilled welders. But while working to keep pace with rising demand for specialized vessels, the ship builder isn’t relying solely on traditional welding methods. Instead, LAD is turning to a technology that was built specifically for the realities of modern shipbuilding.

By partnering with Path Robotics, LAD expects to cut barge production time in half without sacrificing the precision and quality needed to bring its new cutting-edge designs to reality, the release stated.

“The welding craft is aging, quality is under pressure, and skilled welders are getting harder and harder to find,” said LAD Services General Manager Joseph Crappell, in a statement. “We reached a point where we simply could not make everything we needed to make with people alone. Traditional automation could not handle the reality of shipbuilding. Path’s technology gives us the added capacity we need without relying on a shrinking labor pool of welders, while maintaining the quality our customers expect. Path was the only solution that made sense for LAD and we’re confident this will revolutionize the industry.”

Future proofing with Physical-AI for welding

LAD Services is described as a “leader in innovative barge and vessel construction, known for novel structural designs that increase cargo capacity and performance.”

“The company has built a reputation for continuously reinventing how barges are designed and manufactured, combining advanced engineering with deep industry experience to serve customers across commercial and industrial markets,” the release stated.

Before engaging with Path, LAD Services explored building a custom robotic welding system with a dedicated team of welding engineers and talked with numerous automation companies.

According to LAD, none could handle the complexity and variability of shipbuilding, and

only Path Robotics offered the flexibility and intelligence needed for real production.

“Unlike traditional welding automation systems that struggle with the variability inherent in shipbuilding, Path Robotics’ AI-powered welding cells handle the complex, high-mix welding tasks that have historically not been possible to automate, and thus required scarce but valuable human expertise. Path’s physical-AI for welding delivers consistent, high-quality welds with no risk of worker injury and continuous operation, fundamentally changing LAD Services’ production capacity,” the release said.

Vertically Integrated U.S. Defense Technology Company Is ‘Designed for Speed, Adaptability, and Scalability,’ CEO Says

Another company dedicated to enhancing the capabilities of autonomous robots through physical AI is Palladyne AI Corp., a Salt Lake City-based developer of artificial intelligence software for autonomous platforms used in the defense and commercial sectors.

Like Path Robotics, Palladyne AI has developed an advanced artificial intelligence and machine learning (ML) software platform that aims to transform the capabilities of robots by enabling them to “observe, learn, reason, and act in a manner akin to human intelligence.”

“Our AI and ML software platform empowers robots to perceive variations or changes in the real-world environment, enabling them to autonomously maneuver and manipulate objects accurately in response,” company executives said in a release.

According to Palladyne AI, the software operates on the edge (on the robotic system) and is said to dramatically reduce the significant effort required to program and deploy robots. As a result, industrial robots and collaborative robots (cobots) can quickly achieve autonomous capabilities in dynamic or complex environments.

The software is designed to enable robotic systems to perceive their environment and quickly adapt to changing circumstances by generalizing (learning) from their past experience, using dynamic real-time operations on the edge. This eliminates the need for extensive programming and requires minimal robot training, the company said.

Palladyne AI believes its software has wide application, including in industries such as automotive, aviation, construction, defense, general manufacturing, infrastructure inspection, logistics, and warehousing. Its applicability is reported to extend beyond traditional robotics to include unmanned aerial vehicles (UAVs), unmanned ground vehicles (UGVs), and remotely operated vehicles (ROVs).

In November, however, Palladyne AI began expanding its capabilities beyond software by acquiring three companies: GuideTech LLC, Warnke Precision Machining, and MKR Fabricators. The latter two are companies of Crucis LLC, a private investment firm working to help repatriate and reshore the U.S. aerospace and defense supply chain by “scaling U.S. manufacturing companies long-term.”

With the acquisitions, the company created Palladyne Defense, a new operating division of Palladyne AI that unites the capabilities of all three companies. In addition to offering advanced engineering capabilities, the new division will provide patented embodied AI; unmanned aerial vehicle (UAV) and loitering munitions components and systems; and U.S.-based manufacturing. According to Palladyne, it supports the U.S. Department of Defense’s priorities for modernization through achievement of “intelligent autonomy, rapid iteration, low cost per effect, and the reshoring of critical defense production.”

“This marks a defining inflection point for Palladyne AI,” said Ben Wolff, president and CEO of Palladyne AI, in the release. “Through the creation of Palladyne Defense, we are transforming from an AI software innovator into a vertically integrated defense technology company. We are combining breakthrough autonomy with American manufacturing strength to create a defense enterprise that is fast and scalable by design.”

Wolff said that the division merges capabilities for embodied AI and advanced avionics with complete, low-cost, weapons systems and domestic manufacturing into “a single, vertically integrated enterprise designed for speed, adaptability, and scalability.”

“Our vertically integrated model allows us to meet emerging defense and public safety needs while reshoring capability and accelerating innovation,” he continued. “This is how America maintains its technological advantage by building it here, with intelligence at the edge and purpose at the core.”

Uniting 3 core elements

Palladyne Defense aims to form a closed-loop innovation and production system by bringing together and uniting three core elements:

- Embodied AI and Autonomy: Patented software and intelligent control systems that enable edge decision-making, swarm coordination, and adaptive mission execution.

- GuideTech’s Systems, Avionics, and Rapid Design-for-Manufacture Services: Proven design capabilities and advanced avionics, flight systems, and weapons platforms developed through accelerated prototyping and iterative engineering that compress design cycles from years to months.

- US. Manufacturing and Production by the Crucis Companies (Warnke Precision Machining and MKR Fabricators): Precision machining, heavy fabrication, and assembly of electronic and mechanical components that support major defense programs and Palladyne’s future proprietary systems.

Technology integration and reshoring

Palladyne AI emphasized that the creation of its new Defense division aligns with, and supports, one of the DoD’s most critical modernization priorities—the reshoring of essential defense technology and production capacity.

According to Palladyne AI, its integration of advanced avionics, flight software, and system engineering from GuideTech enables it to reduce design-to-prototype timelines from years to months. From there, Palladyne can leverage what it described as the “full-spectrum domestic manufacturing capabilities” of Crucis companies Warnke Precision Machining and MKR Fabricators.

In addition to precision machining, fabrication, and assembly for air, land, and sea systems, these new acquisitions bring direct access to their existing defense prime customers, such as Lockheed Martin, and the Boeing and Kratos teaming project.

“Together, these capabilities will enable Palladyne Defense to design, develop, and produce components and complete systems entirely within the United States in the near future, strengthening supply chain security and ensuring sustained access to mission-critical components,” the company said in the release.

GuideTech Co-founder and President James Cook said that joining Palladyne AI allows its team to accelerate commercialization and strengthen its competitive position. “By combining autonomy, avionics, and manufacturing at scale, we can deliver faster, smarter, and more affordable solutions to our customers.”

GuideTech designs and builds advanced flight software, avionics, and control systems for unmanned aerial, space, and missile platforms. Its BRAIN series of guidance and navigation avionics, along with its FLEX modular software platform, are deployed across multiple defense programs.

“GuideTech helps aerospace startups and prime contractors rapidly develop high-performance unmanned systems at lower cost and with faster turnaround,” the company’s website states.

“We pair prime-level engineering rigor with startup agility.”

According to GuideTech, the company’s vision is to pioneer “nimble aerospace and defense solutions for the future.”

“GuideTech breaks the mold by providing engineering solutions, products, and integrated systems with the same rigor as major aerospace primes, but at a pace that’s remarkably faster, costs significantly less, and achieves exceptional performance,” the company’s LinkedIn page states. “We specialize in autonomous systems, specifically guidance navigation and control (GNC), modeling and simulation (M&S), real-time embedded software, digital signal processing, computer- and hardware-in-the-loop integration and test, and mechanical and dynamic systems.”

The other two acquisitions, Warnke Precision Machining (Oxford, Michigan) and MKR Fabricators (Saginaw, Michigan), are well-established U.S. manufacturing stalwarts. As part of Crucis, they not only provide advanced precision machining, heavy fabrication, and assembly for the aerospace and defense sectors, but are reported to have “deep expertise in U.S. manufacturing and defense supply chain operations.” Programs that they support are reported to include the F-16, F-35, Tomahawk, JDAM, P-JDAM, M1A1 Abrams, Harpoon and Bradley Fighting Vehicle.

According to Palladyne AI’s website, Warnke Precision’s core capabilities span prototyping to production, including CNC turning and milling, multi-axis machining centers with live tooling for complex geometries, and precision grinding and boring. Providing scalable support from design validation to full-rate production runs, the company prides itself on achieving “tight tolerances and exceptional surface finishes.” To ensure aerospace-grade execution, Warnke Precision adheres to standards such as AS9100D and ISO 9001:2015.

Warnke’s key strengths are reported to include experienced machinists and engineers committed to precision and reliability, as well as state-of-the-art equipment for both rapid-turn and high-volume production. The company’s website stated that it also has a “proven track record serving Tier-1 and OEM suppliers across high-performance industries.”

MKR Fabricators offers comprehensive heavy fabrication and machining services from its 65,000-square-foot facility in Saginaw. Its expertise spans “steel structures, industrial assemblies, and large-scale custom fabrications across various sectors, including mining, agriculture, aerospace, defense, energy, infrastructure, dredging, and transportation,” according to Palladyne AI’s website.

The company’s core capabilities are reported to encompass heavy plate rolling and forming, complex curvature forming, large-scale welding and assembly, CNC machining of large components, and integration of fabrication and machining under one roof. The company’s AWS-certified welders and submerged arc systems are said to ensure precision structural welds.

A key strength of MKR Fabricators is its lifting and handling capacity up to 25 tons and fabrications exceeding 60 feet in length. Other key strengths are its experience in delivering durable, high-quality assemblies for industrial and government clients, and its versatility to manage one-off builds, modular systems, and full production contracts, according to the website.

Today, Palladyne Manufacturing describes itself as “a U.S.-based manufacturing group dedicated to rebuilding America’s industrial strength. The mission is clear: to revitalize and reshore critical manufacturing capacity, ensuring that the technologies and components essential to the nation’s future are built with excellence, reliability, and pride right here in the United States.”