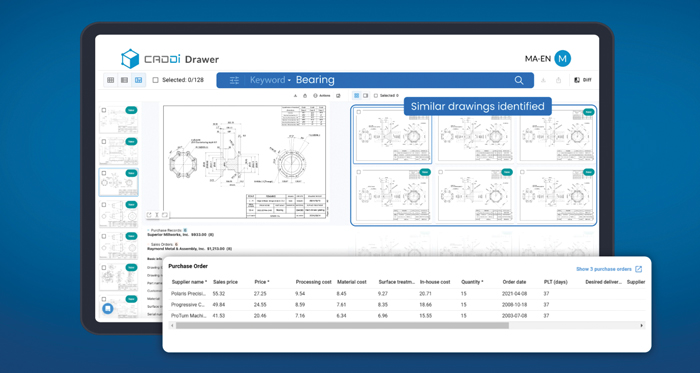

A preview of CADDi Drawer. Through the CADDi platform, including its CADDi Drawer application, Mitsubishi Materials USA enabled teams to search by easy-to-access information, including customer, tool number, or quote ID, and immediately retrieve related drawings, inspection reports, prior decisions, and more. (Image courtesy CADDi)

A new case study from CADDi details how Mitsubishi Materials USA used AI-powered drawing intelligence to improve quoting speed, engineering reuse, and cross-team data access.

CHICAGO—CADDi, a developer of manufacturing-exclusive AI data platforms that serve as a shared intelligence layer across engineering, sales, and operations, recently released a new customer case study developed with Mitsubishi Materials USA.

CADDi developed its AI powered data platform to make design and supply chain data accessible and actionable for manufacturing teams. Its flagship product, CADDi Drawer, uses advanced AI to centralize and analyze unstructured design and production data, helping manufacturers improve efficiency, reduce redundancies, and unlock innovation, the company said in a release.

“This case study shows how making engineering data visible across teams directly improves speed, consistency, and decision quality,” said Yushiro Kato, CEO and co-founder of CADDi, in the release.

Manufacturers move beyond tribal engineering knowledge

According to CADDi, manufacturing organizations are increasingly realizing the need for shared, decision-grade intelligence that sales and engineering teams can access independently, rather than relying on specific knowledgeable employees. This shift reflects growing pressure to respond faster to custom work while maintaining consistency, as teams scale and experienced staff retire from the workforce.

Manufacturers supporting high-mix, custom production have relied on years of engineering drawings, pricing history, and quality records. However, these data resources are often difficult to locate and reuse. When this information is fragmented across systems or individuals, teams lose time by coordinating, recreating work, and waiting on internal handoffs.

“We are seeing a clear shift in how manufacturers operate,” Kato continued. “They’re evolving away from the era of tribal engineering knowledge as a bottleneck in decision-making. Manufacturers already have the knowledge they need to work faster and smarter. The most common challenge our customers face is access.”

Turning decades of engineering data into shared intelligence

Founded in 1984, Mitsubishi Materials USA is part of the Mitsubishi Materials group, a global materials and manufacturing company headquartered in Japan. The company provides cutting tools and engineered carbide solutions for turning, milling, drilling, and wear-resistant applications to manufacturers across North America.

The Mitsubishi Materials USA team implemented the CADDi AI data platform to make their repository of engineering and sales data more searchable and insightful. (Photo courtesy of Mitsubishi Materials USA)

Through the CADDi platform, including its CADDi Drawer application, Mitsubishi Materials USA enabled teams to search by easy-to-access information, including customer, tool number, or quote ID, and immediately retrieve related drawings, inspection reports, prior decisions, and more.

“This quick access reduced manual coordination, improved response times for custom requests, and minimized duplicate engineering effort,” the release stated. “Sales teams gained direct access to the information needed to estimate costs for and respond to custom requests, while engineering teams benefited from easier reuse of prior designs and decisions.

Enabling faster decisions without increasing reliance on individuals

The case study highlights how Mitsubishi Materials USA enabled sales and engineering teams to independently access historical engineering drawings, quotes, and related records. By reducing reliance on manual handoffs and making this information searchable and reusable across teams, the company accelerated response for custom work while improving consistency across quoting and engineering workflows, CADDi stated in the release.

Centralized access to engineering history also helped standardize how past designs and quality outcomes informed new work. This supported continuity as projects scaled and personnel changed, reducing dependency on individual knowledge holders. A regional sales manager at Mitsubishi Materials USA described the impact on daily work.

“It’s a huge time saver. Being able to search for a quote number, tool number, or customer and get exactly what I need without maintaining it on my own has changed how we work.”

The complete case study is available at us.caddi.com/case-studies.

See R&D Teams Use Data Intelligence Platform to Reduce Engineering and Production Search Time for a case study on how a U.S. manufacturer made its design and supply chain data accessible and actionable for its manufacturing teams.