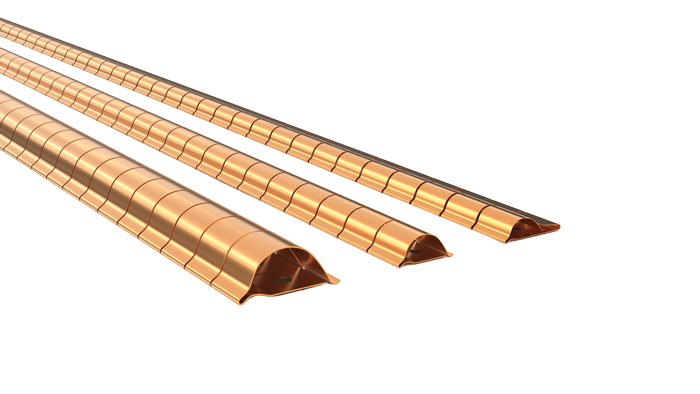

Tech Etch Enclosure Shielding Gaskets are manufactured in Tech Etch’s U.S. facilities, all of which are certified to ISO 9001:2015, AS9100D, and ISO 13485:2016 to ensure product consistency and quality. (Image courtesy Tech Etch)

PLYMOUTH, Mass.—A new line of enclosure shielding gaskets introduced by Tech Etch is engineered to deliver high-performance EMI/RFI shielding for demanding electronic enclosures and cabinet applications, the company said in a release.

Designed and manufactured by Tech Etch’s team of employee-owners, the gaskets are reported to provide consistent electrical performance, exceptional durability, and long-term reliability for mission-critical systems.

Crafted from high-performance beryllium copper, the new gasket line includes Folded Fingerstock and Fold-Over Fingerstock configurations. Each profile is designed to accommodate a range of compression forces while maintaining excellent conductivity and wear resistance. As a result, they are said to be well-suited for cabinet doors, rack-mounted systems, and high-cycle enclosures where sealing integrity cannot be compromised.

According to Tech Etch, the gaskets include the following key features:

- Robust EMI/RFI Shielding: Engineered and tested to meet MIL-STD electromagnetic shielding requirements.

- Durable, Snag-Free Construction: Reinforced gasket bases and smooth profiles support frequent opening and closing without deforming.

- Enhanced Finger Protection (Fold-Over Models): Fold-over profiles safeguard contact fingers, maintaining conductivity even under repeated compression.

- Versatile Installation Options: Available with traditional non-conductive adhesive; additional configurations available upon request.

“At Tech Etch, our mission is to engineer solutions that enhance lives globally,” said Scott Lewis, EMI Business Development at Tech Etch, in the release. “Our new Enclosure Shielding Gaskets reflect the innovation, precision, and quality our customers expect, while expanding the shielding options available for both commercial and high-reliability applications.”

The Enclosure Shielding Gasket line is manufactured in Tech Etch’s U.S. facilities, all of which are certified to ISO 9001:2015, AS9100D, and ISO 13485:2016 to ensure “the highest levels of product consistency and quality,” the company said.

Tech Etch has more than six decades of experience and expertise in manufacturing precision-engineered thin metal components, flexible printed circuits, and EMI/RFI shielding. The company operates three facilities in the United States, with locations in Plymouth, Massachusetts, Fall River, Massachusetts,, and Litchfield, Minnesota.

“Tech Etch partners with leading global customers in the aerospace, alternative energy, military, medical, telecommunication, and electronics industries that have precise designs and demanding regulatory requirements,” the release stated.