The company won top honors at the AM Bench 2025 Challenge for predicting phase transformations in Fe-Cr-Ni alloys.

EVANSTON, Ill. and CAMBRIDGE, Mass.—QuesTek Innovations, a developer of simulation-based materials design and engineering software, was awarded first place in the AM Bench 2025 modeling competition for CHAL-AMB2025-08: Phase Transformation Sequence, the company said in a release.

The award recognizes the company’s ability to accurately predict how phases evolve during laser melting of Fe-Cr-Ni alloys, materials widely used in metal additive manufacturing (AM).

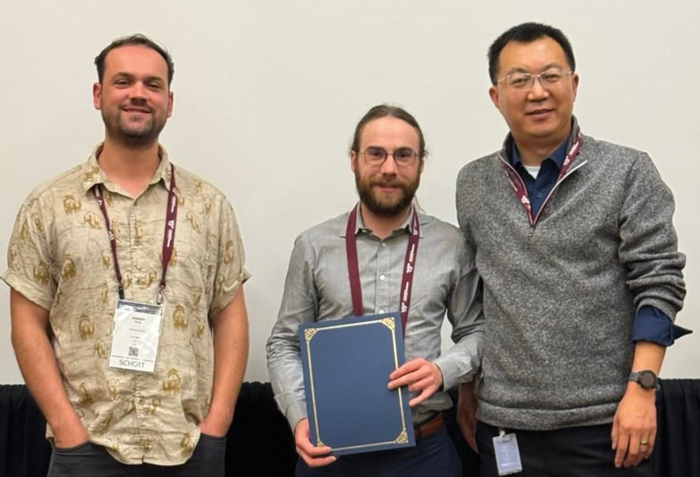

QuesTek’s Orion Kafka (center), flanked by NIST’s Joseph Aroh (left) and Fan Zhang (right), is shown with the first-place award for QuesTek Innovations at the AM Bench 2025 modeling competition. (Image: PRNewswire)

AM Bench is a program led by the National Institute of Standards and Technology (NIST). It provides high-fidelity benchmark measurements and challenge problems that allow modelers to validate simulations against rigorous experimental data. The 2025 program was held in conjunction with the American Society of Mechanical Engineers’ (ASME’s) International Mechanical Engineering Congress & Exposition (IMECE), where winners were announced during a special awards dinner.

Challenges like AM Bench play an essential role in advancing the additive manufacturing industry, according to QuesTek. As companies and research groups increasingly rely on computer models to guide material and process development, it becomes critical to test those simulations against trusted, independent datasets.

The AM Bench modeling program provides that neutral proving ground. By comparing different modeling approaches against the same measurements, the program helps the community identify what works, understand where improvements are needed, and accelerate the adoption of reliable predictive tools across manufacturing sectors.

“This win reflects more than technical accuracy, it signals where the field is going,” said Jason Sebastian, executive vice president at QuesTek Innovations, in a statement. “Additive manufacturing is moving toward a future where materials and processes are digitally validated long before fabrication. Our performance in this benchmark demonstrates that QuesTek’s simulation capabilities are helping lead that transition, giving industry a faster and more confident path from concept to qualification.”

The challenge focused on predicting the sequence of phases that form during rapid solidification in Fe-Cr-Ni alloys with different Cr/Ni ratios. These alloys serve as a model system for many stainless steels, and are particularly relevant to additive manufacturing because the process involves intense heating and cooling cycles that drive phase evolution differently from traditional manufacturing methods.

QuesTek’s winning effort used solidification microstructure models included in QuesTek’s Materials by Design® technology. The technology suite, embodied in QuesTek’s ICMD® SaaS offering, was recently enhanced to improve support for alloy and process design for additive manufacturing, the company said in the release.