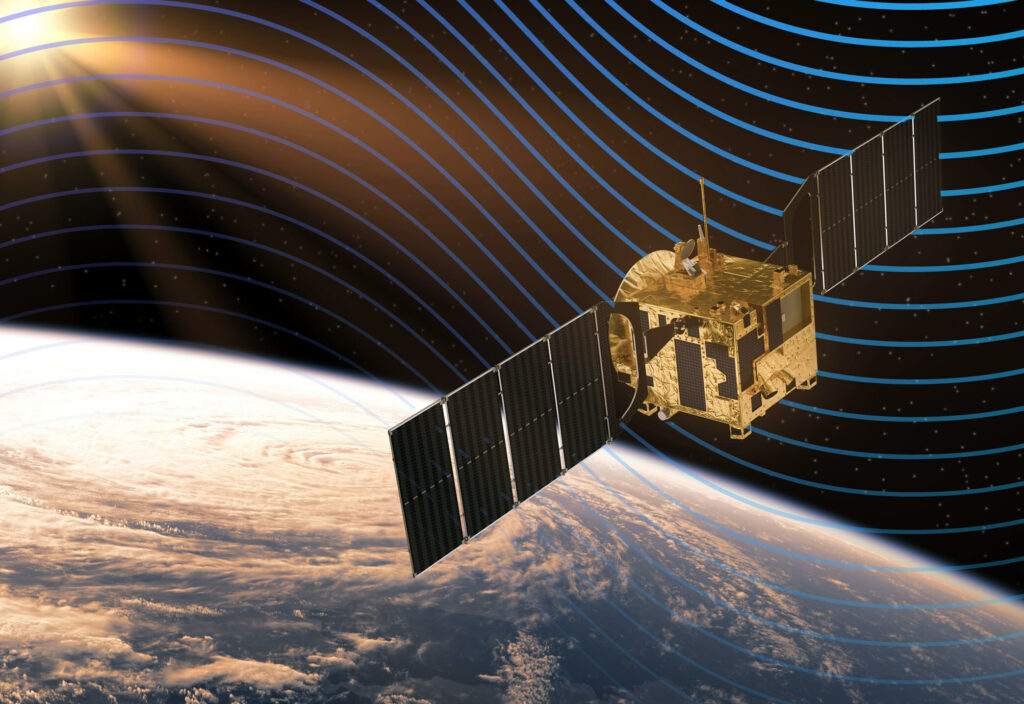

Additive Manufacturing Enables New Approach to Antenna Design

Vitesse Systems recently delivered what a company official described as its

“most complex space hardware to date”—an antenna comprising 1,600 individual additively-manufactured RF components. (Image courtesy Vitesse Systems)

NEWARK, Calif.—What is believed to be “one of the largest additively manufactured satellite antennas in history” was completed by Vitesse Systems recently and delivered to its customer. Vitesse Systems designed, built, and tested the antenna at its antenna center of excellence in Longmont, Colorado, the company said in a release.

Vitesse uses additive manufacturing to design and print antenna and thermal management products for defense and space applications. The company recently completed installation of two additional additive manufacturing machines, part of a multimillion-dollar investment to expand its additive manufacturing capabilities.

“Additive manufacturing offers distinct advantages that we have been able to leverage to enhance the design of our offerings,” said Vitesse Systems General Manager Richie Dart, in the release. “Since installing our first additive machine in 2021, we have completely rethought our approach to designing certain types of antennas. This is particularly beneficial for space applications where mass and size are critical, and for ground applications where operating over a broad range of frequencies is increasingly important for both defense and civil applications.”

Vitesse Systems specializes in design, build, and test of critical products for electronic warfare, radar, and next-generation communications across air, ground, sea, and space. The company is headquartered in Newark and operates facilities in California, Colorado, Maryland, Massachusetts, and Nevada. All Vitesse facilities are ITAR Registered and DFARS compliant, serving a broad spectrum of aerospace and defense customers, the release stated.

Dart said Vitesse Systems recently delivered its most complex space hardware to date—an antenna comprising 1,600 individual additive RF components. It all began when a customer approached Vitesse in 2022, seeking an antenna partner to support their satellite technology roadmap. By collaborating with its customers from the concept stage, Vitesse was able to leverage the combined benefits of its space heritage and additive manufacturing.

“This allowed us to reduce the overall size and mass of the antenna by 30 percent, optimize RF performance, and deliver the antenna in less than two years,” he explained. “Additive manufacturing builds the antenna layer by layer, which allows us to eliminate internal features that are only there for structural reasons. This not only improves RF performance but also reduces the mass and overall size of the antenna—a fundamental shift for satellite applications, allowing our customers to utilize available space and mass for other purposes.”

Dart further explained that Vitesse has combined additive manufacturing with its existing antenna manufacturing processes for ground-based antennas.

“This allows us to design more capability into a single antenna, enabling our customers to communicate with airborne and space-based assets across a broad range of frequencies and orbits,” he said. “Furthermore, our customers require solutions within increasingly shorter timeframes, often weeks, not months. Our additive capability, combined with our RF expertise and in-house testing capabilities, allows us to exceed our customer expectations.”

Vitesse Systems CEO Matthew Alty said that expanding its additive manufacturing capacity is part of the company’s broader investment strategy to meet the growing demand for high-performance antennas.

“Over the past few years, we have expanded our engineering, manufacturing, and test capabilities as the government has fundamentally changed how military programs are procured,” he said in a statement. “Development timelines have been compressed, and performance requirements have increased as the connected battlefield has become a reality and the number of satellites and interconnected platforms has increased significantly. In response, we have had to rethink how we design, manufacture, and test our antennas. Additive manufacturing, combined with our in-house design and testing capability, allows us to significantly reduce the amount of time it takes from design concept to reality.”

Manufacturing facilities operated by Vitesse Systems include California Brazing, in Newark, California; Custom Microwave Inc., in Longmont, Colorado; Products Support, Inc., in Jessup, Maryland; Sterling Precision, in Clinton, Massachusetts; and Nevada Heat Treating, in Carson City, Nevada.

Through these facilities, Vitesse Systems offers a range of capabilities spanning engineering and design through testing. In addition to additive manufacturing, they include vacuum brazing, dip brazing, precision machining, electroforming/electroplating, heat treating, and assembly.

Companies Partnering to Advance 3D Printing for Hypersonics, UAVs

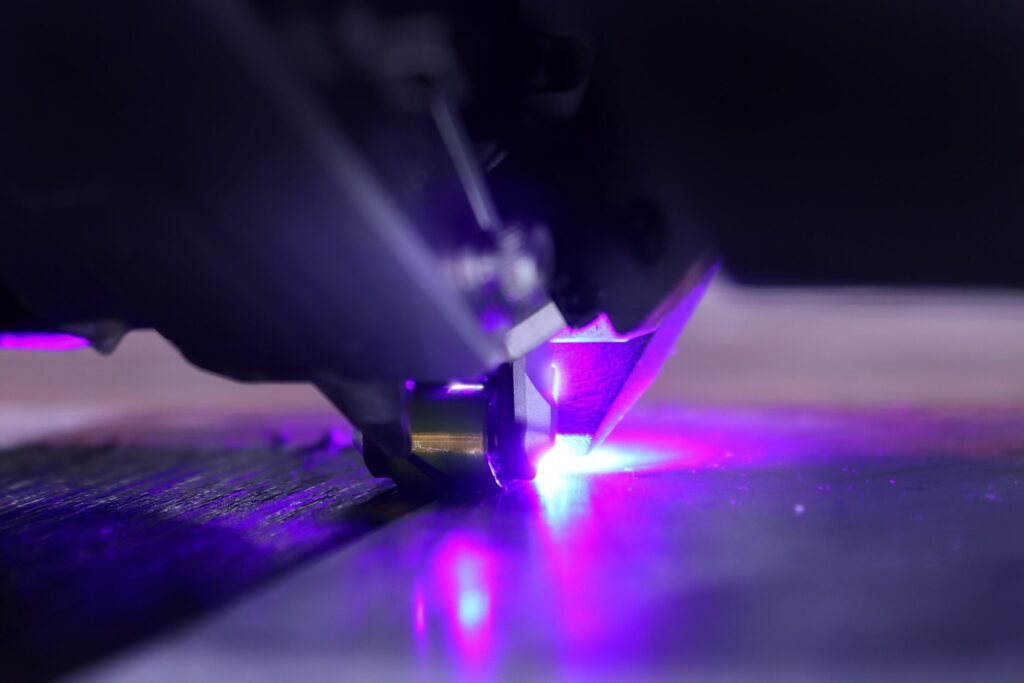

A CF3D print head. (Image courtesy ADDMAN/Continuous Composites)

FORT MYERS, Fla.—Last fall, ADDMAN Group reported that it began partnering with Continuous Composites to scale Continuous Fiber 3D Printing (CF3D®) for aerospace and defense applications.

In a release announcing the strategic partnership, ADDMAN stated that as the commercial transition partner, it will produce test parts and prototypes, propelling CF3D into high-stakes applications such as hypersonics and unmanned aerial vehicles (UAVs).

Continuous Fiber 3D Printing uses high-performance composite materials and rapid-curing thermoset resins to create complex, multifunctional parts with structural and functional fibers.

Through their strategic partnership, the companies are now “setting a new standard in additive manufacturing for aerospace and defense, driving innovation in high-temperature and lightweight applications,” according to the release.

“We believe that our CF3D continuous fiber technology has the potential to significantly impact cost, lead time, and part performance across many industries,” said Steve Starner, president and CEO of Continuous Composites, in the release. “Our goal is to deliver an unmatched manufacturing system in aerospace and defense. ADDMAN’s broad experience and best-in-class technical expertise in aerospace and [in] high-temperature thermal protection systems in hypersonics make us ideal partners to support further adoption of this compelling technology.”

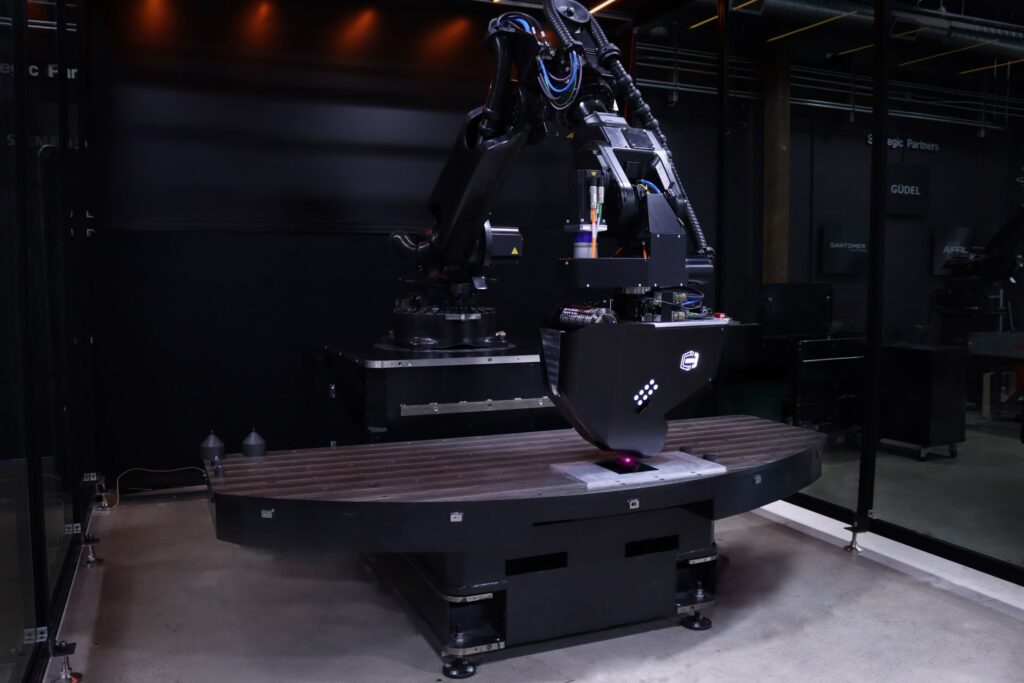

ADDMAN has installed a CF3D machine at its Fort Myers headquarters and innovation center, reportedly becoming the only service bureau to offer both carbon-carbon composite and refractory alloy printing. The capability is said to align seamlessly with ADDMAN Group’s Castheon 3D-printed niobium alloys, including niobium C103 and Niobium Super C103, which offer critical benefits for hypersonic applications.

An enclosure of a CF3D work cell. (Image courtesy ADDMAN/Continuous Composites)

The CF3D machine uses a continuous dry fiber, impregnated in real-time with a rapid-curing thermosetting resin, to enable precise, large-scale printing of composite parts measuring 2.7m x 1.1m x 1.1m. Driven by proprietary software and advanced numeric controllers, the system is said to ensure high accuracy and instant curing upon deposition, accommodating complex designs with structural and functional fibers tailored for demanding applications.

“Integrating CF3D technology into ADDMAN’s suite of capabilities directly addresses feedback from our customers, who have emphasized the need for both carbon-carbon composites and refractory metals like Niobium C103 to support their advanced applications,” said Joe Calmese, CEO of ADDMAN Group, in the release. “This integration allows us to provide optimized solutions for performance and weight, delivering mission-critical components that meet the stringent requirements of hypersonic systems. By aligning our solutions with market needs, we reinforce our role as a comprehensive partner for aerospace and defense innovations.”

ADDMAN Group is a vertically integrated manufacturer that specializes in additive manufacturing, CNC machining, injection molding, and advanced composites. The company provides tailored manufacturing services to customers in the aerospace, medical, defense, and industrial sectors, helping them bring complex, innovative products to market.

Continuous Composites, based in Coeur d’Alene, Idaho, is a pioneer in composite 3D printing technology. Through its work, the company supports customers in industries such as aerospace, defense, and automotive. Its patented CF3D® technology is reported to combine high-performance continuous fibers with advanced thermoset resins to produce complex, lightweight structures with exceptional strength.

Composite Materials Could Enable Parts to Withstand Extreme Temperatures in Hypersonic Flight

A rocket nozzle incorporates Cambium’s ApexShield 1000 high-temperature resin system. (Image courtesy Cambium Biomaterials Inc. / PRNewswire)

Cambium is working under contract with the U.S. Navy to significantly reduce the costs and lead times required to produce the high-temperature material systems.

EL SEGUNDO, Calif.—Through a contract with the U.S. Navy, advanced materials company Cambium Biomaterials is working to optimize the processing and production of its phthalonitrile material systems. Its goal is to ensure the advanced high-temperature composites “continue to deliver on their potential to massively reduce the cost and time needed to produce hypersonics-ready parts by around 70 percent,” Cambium said in a release.

According to Cambium, its AI-driven material discovery and development platform enables the company to more rapidly and cost-effectively produce hypersonics-ready products through a domestic supply chain. The phthalonitrile systems are composite materials that are engineered to provide thermal protection for parts in high-temperature environments.

“Our phthalonitrile material systems deliver not just performance but also unprecedented production speed and capacity to the U.S. Department of Defense and Program of Record prime contractors and subcontractors—two of the highest priorities in U.S. defense today,” the company stated in the release.

Cambium said it is working with a sense of urgency to optimize these thermal protection systems in its contract with the Navy’s Office of Naval Research (ONR). Under the contract, Cambium is working to create a secure domestic supply for hypersonics by significantly reducing lead times and cost roadblocks.

The company’s phthalonitrile-based high-temperature composite materials are reported to address key issues in processing and production that had hindered adoption and were thought to be insurmountable. Companies have been unwilling to take on the risks of solving these issues, according to the release.

Consequently, the defense industrial base has, until now, lacked access to phthalonitrile-based products from which to build the “carbon-carbon parts that can survive and perform in the extreme conditions that structures encounter at hypersonic speeds up to Mach-20,” the company said.

“The U.S. must establish a secure, scalable supply chain for advanced materials to support hypersonic systems at speed and scale,” said Simon Waddington, Cambium’s so-founder and CEO, in a statement. “Cambium is tackling this challenge head-on, developing next-generation thermal protection systems that are not only high-performing but also cost-effective and domestically manufactured. This Navy contract is another step forward in our mission to deliver cutting-edge materials solutions that strengthen national security and technological leadership.”

Cambium describes its advanced material development platform as a first-of-its-kind platform that molecularly re-engineers polymers from first principles for exceptional performance, survivability, and manufacturability. It uses a suite of computational methods combined with state-of-the-art materials science, chemistry, and biology, the company said.

“We manufacture products in a secure domestic supply chain using flexible production systems that offer defense customers and other innovators the speed and flexibility to develop critical products,” the company said in the release.

Three weeks after announcing its contract with the Navy, Cambium introduced its ApexShield 1000 high-temperature resin system for aerospace manufacturers.

The resin system is reported to “massively increase” the speed of producing carbon-carbon parts for glide bodies and other components critical for hypersonic applications, including rocket nozzle extensions. It is also said to bring significant benefits to ablative applications, such as solid rocket motor nozzles and vertical launch tubes on ships.

According to Cambium, the optimized resin system reduces carbon-carbon parts fabrication to 1-2 polymer infiltration and pyrolysis (PIP) cycles, a reduction of 70 to 80 percent over legacy systems. “Cambium is the first to achieve this PIP cycle breakthrough, which will allow parts manufactures to cut production time from 6-9 months to 1-2 months—and reduce costs proportionately,” the company said in the release.

The Thermal Protection Resin System has a low melt viscosity that is suitable for vacuum assisted resin transfer molding (VaRTM) or resin transfer molding (RTM) applications. The system is room temperature stable, eliminating the need for freezer storage, and is being produced at metric-ton scale, the release stated.

Cambium Vice President of Composite Products Nate Monroe said the new phthalonitrile material systems “deliver a whole new level of production speed and capacity to the US DoD, prime contractors and subcontractors, a key priority for US defense today.”

“Carbon-carbon part production is a serious bottleneck holding back the rapid and cost-effective production of hypersonic-ready products,” Monroe said in a statement. “Cambium’s solution dramatically increases the production throughput with breakthrough advanced materials that can be processed utilizing existing infrastructure wholly within a domestic supply chain.”

Cambium used its AI-driven material discovery to optimize the processing and production of the phthalonitrile-based resin systems in collaboration with U.S. Department of Defense laboratories, industry partners, and the Bioindustrial Manufacturing and Design Ecosystem (BioMADE), the company said in the release.

Military Coatings Specialist Combines ‘Cutting-Edge Technology with Time-Tested Expertise’

Heritage Industrial Finishing specializes in coatings engineered to withstand extreme environments and extend equipment lifespans. (Photo: Business Wire)

Heritage Industrial Finishing is the primary coating contractor for the MK84 Bomb project.

AKRON, Ohio—On defense projects where Heritage Industrial Finishing partners with customers, failure is not an option. Heritage has served as a trusted partner to defense OEMs across North America since 1965, delivering military coatings that “ensure operational readiness and longevity for critical defense assets,” the company said in a release.

The long-standing military coatings specialist was recently selected as the primary coating contractor for the MK84 Bomb project, a cornerstone of modern defense systems. The strategic partnership is said to underscore Heritage Industrial Finishing’s expertise in precision coatings and its proven ability to meet the rigorous demands of manufacturing for military OEMs.

“Being chosen for the MK84 project is a testament to our team’s relentless commitment to quality and innovation,” said Heritage Industrial Finishing President and CEO Nick Pamboukis, in a statement. “For decades, we’ve partnered with military OEMs and manufacturers to deliver coatings that protect mission-critical assets. This contract reaffirms our position as the industry’s most reliable coater, combining cutting-edge technology with time-tested expertise.”

The MK84 Bomb is described as “a critical component in global defense operations,” requiring coatings that ensure durability, corrosion resistance, and mission readiness. Heritage Industrial Finishing specializes in coatings engineered to withstand extreme environments and extend equipment lifespans.

The company said in the release that it is known for its technical mastery and adherence to the highest industry standards, with approvals from leading defense manufacturers to match. In addition to its MIL-SPEC compliance and ISO certifications, Heritage holds approvals from top-tier military OEMs such as Raytheon, AM General, Oshkosh Defense, General Dynamics, BAE, and several others. As a result, its finishing services are said to “ensure seamless integration into OEM supply chains.”

Sierra Space Completes Test Campaign for Next Generation Upper-Stage Engine

Sierra Space reported that it successfully completed the test campaign for its fully integrated VR35K-A upper stage engine, marking a major step forward in the company’s development of advanced propulsion systems. (Photo: Sierra Space)

The liquid oxygen / liquid hydrogen engine employs a fuel-rich staged combustion cycle.

LOUISVILLE, Colo.—Sierra Space, a commercial space company and defense tech prime contractor, recently completed the test campaign for its fully integrated VR35K-A upper stage engine, marking what the company called “a major step forward” in its development of advanced propulsion systems.

Sierra Space completed the test campaign under contract with the U.S. Air Force Research Laboratory’s (AFRL) Rocket Propulsion Division at Edwards Air Force Base, in California, the company said in a release.

The company was also awarded a $16 million firm-fixed-price contract from AFRL to continue upper-stage engine maturation to fulfill future National Security Space Launch (NSSL) missions. This is a follow-on to a $22 million-plus contract awarded to Sierra Space in July 2023 by the Air Force Test Center at Edwards Air Force Base, the release stated.

The VR35K-A is a high-performance liquid oxygen (LOX)/liquid hydrogen (LH2) engine that employs a fuel-rich staged combustion cycle, an innovative turbopump architecture, and a VORTEX® combustion chamber to produce 35,000 lbf (pound-force) of thrust at “a higher performance than any engine currently on the market,” according to the release.

Sierra Space’s patented VORTEX technology is said to enable efficient and stable combustion while providing active cooling for the combustion chamber, ensuring high performance and reliability. Dan Polis, vice president of engineering solutions and propulsion systems at Sierra Space, said the engine is a testament to the company’s “commitment to pushing the boundaries of space commercialization with cutting-edge, scalable solutions.”

“Our powerful new upper stage engine, the VR35K-A, represents a groundbreaking advancement in propulsion technology, leveraging Sierra Space’s patented VORTEX engine design to achieve unprecedented efficiency, reliability, and affordability,” Polis said in a statement. “We are delivering high performance, reduced complexity, and significant cost savings with this revolutionary new product, allowing our customers and partners to deliver up to 30 percent more payload mass to orbit.”

One of the key attributes of the VR35K-A, according to Sierra Space, is simplified operation. It includes a single-shaft turbopump assembly for streamlined functionality, including start-up and shut-down. The engine also features mechanically-coupled mixture ratio control that is said to ensure precise fuel and oxidizer balance. In addition, additive manufacturing reduces production costs and lead times for complex components, the company said in the release.

The engine underwent a rigorous test campaign in 2024 at Sierra Space’s Badger Propulsion Test Facility in North Freedom, Wisconsin, and is reported to have achieved all objectives. These include stable, efficient thrust chamber operation; robust and efficient turbomachinery operation; mixture ratio control; throttle demonstration; and high overall engine efficiency.

Sierra Space partnered with Florida Turbine Technologies, a subsidiary of Kratos Defense & Security Solutions, Inc., to develop and test the turbomachinery used in the VR35K-A engine.

“Kratos is a leader in propulsion technology, dedicated to the rapid development, demonstration, and deployment of innovative solutions,” said Stacey Rock, president of Kratos’s Turbine Technologies Division, in a statement. “Our philosophy is to collaborate with industry leaders who share our mission of delivering cutting-edge technologies and capabilities to market quickly and cost-effectively. This partnership with Sierra Space has been highly successful and represents a cornerstone of our long-term strategic initiatives.”

Sierra Space said its VR35K-A engine will serve a critical industry need in supporting larger payload delivery to Low Earth Orbit and beyond. The company is also applying its VORTEX combustion chamber technology to engines and thrusters to support in-space propulsion for spacecraft orbital maneuvering and extraterrestrial landers. Sierra Space’s Dream Chaser® spacecraft uses VORTEX in its reaction control system thrusters, for example.

In 2023, Sierra Space reported that the VR35K-A had completed engine component testing, which allowed the company to advance to the full engine hot fire testing campaign. Next, the company is planning to continue maturing its upper stage engine technology as it moves into a more extensive qualification phase, the release stated.

As it delivers orbital services to commercial, DoD, and national security organizations, Sierra Space said it is expanding production capacity to meet the needs of constellation programs. The company also builds systems and subsystems across solar power, mechanics and motion control, environmental control, life support, propulsion, and thermal control.