The MAKEiT 2×4+ Large Format 3D Printer can print a part as large as 55 by 26 by 31 inches. (Photo courtesy MAKEiT, Inc.)

MAKEiT’s large format 3D printers specialize in printing glass fiber nylon (PA6GF) and carbon fiber nylon (PA6CF) filaments for a range of applications, including automotive.

By Mark Shortt

ALHAMBRA, Calif.—MAKEiT Inc. is a manufacturer of large format 3D printers capable of making anything from a custom body mold for a race bike to a full-size fender for a car. Its printers, designed from the ground up by CEO and Chief Technology Officer Salomo Murtonen, have been used to create sections of what is reported to be “the tallest 3D printed human statue” and a Corvette C7 hood that was printed in halves in two separate runs.

But it’s not just their ability to create big parts that sets MAKEiT 3D printers apart from most other 3D printers. They are also valued for their ease of operation, faster prototyping, and ability to handle the abrasive, high-temperature materials needed to produced strong, stiff, lightweight parts.

MAKEiT President Shelley Sun said the company’s U.S.-made 3D printers provide dependable performance with no need for users to “baby sit” the machine. Their large format 3D printing technology helps industrial design and fabrication companies “accelerate prototyping and pilot production, reduce costs, and optimize processes,” Sun stated in an emailed response to Design-2-Part.

“We make quality and dependable large format 3D printing equipment in California for design, engineering, and fabrication firms,” MAKEiT’s website states. “After years of working with various car designers and custom shops, we have created and developed a large format 3D printing equipment system suitable to operate in small or large shops, 24/7.”

Do-it-for-you service

Besides making and selling MAKEiT large format 3D printers, the company also provides large format 3D printing services to individuals and companies who don’t want to operate printers, according to Sun. Its client list includes companies and organizations in fields ranging from advertising, education, and research, to aerospace, agriculture, automotive, and transportation.

“We offer a do-it-for-you 3D printing service,” she said. “An STL file is generated based on our specific requirements; we then 3D-print the model.”

The company has worked closely with custom auto shops to 3D print large panels, including grills, front bumpers, fenders, hoods, skirts, and wings, using glass fiber nylon (PA6GF) material, according to its website. Some of the carbon fiber nylon (PA6CF) parts made by its printers have been installed on race car bodies. Both materials combine stiffness and strength with light weight and are a specialty of MAKEiT printers.

“These materials are the best materials to make car plugs, master molds, or end use parts,” the website stated. “You can sand them freely with a power sander, [and] unlike PLA, they don’t melt or deform.”

Ease of operation and factory-direct tech support

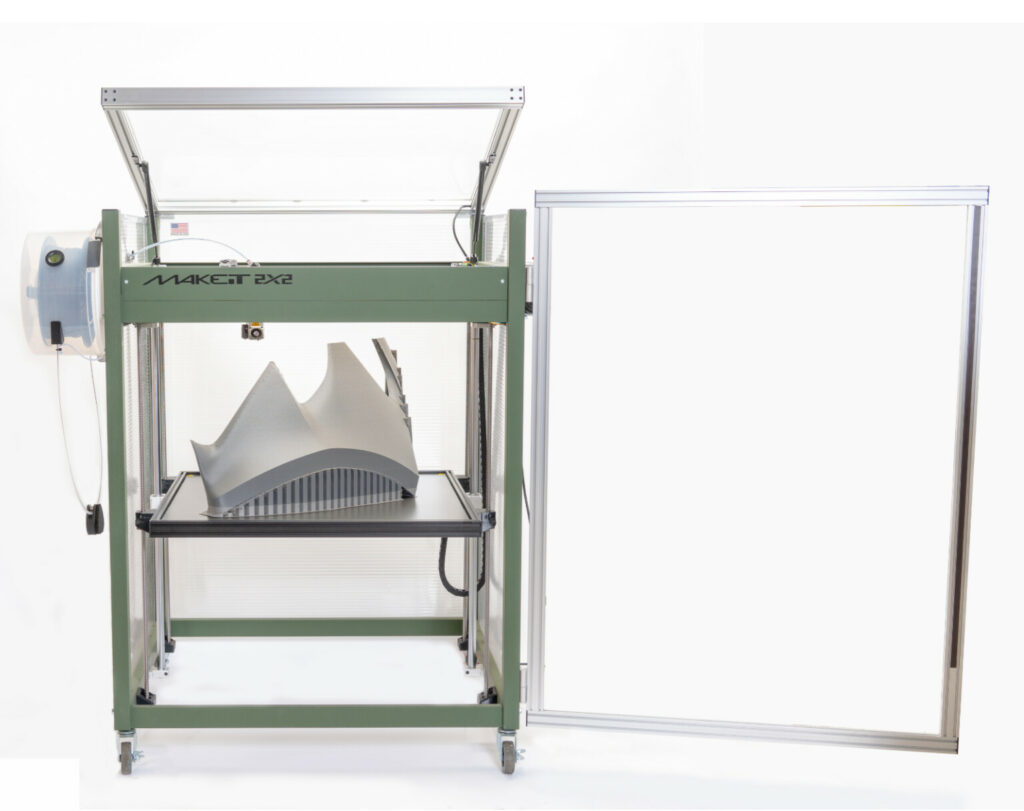

For customers who prefer to do their 3D printing in-house, MAKEiT offers two large format 3D printers—the MAKEiT 2×2 and 2×4+ 3D printers—that are “fully assembled and well-tested” before the customer receives them.

The MAKEiT 2×2 can print a single part measuring 26 by 26 by 31 inches. For larger designs, customers can use the MAKEiT 2×4+ to print a part as large as 55 by 26 by 31 inches. Both printers are capable of transforming digital designs from a 3D model to a life-size physical part or mold, accurately and symmetrically.

“When making a plug for a custom widebody kit, the technology is fast and requires no extra tooling and much less handwork than traditional clay-based or cardboard-based methods,” Sun explained.

A MAKEiT 2×2 3D Printer, capable of printing a single part measuring 26 by 26 by 31 inches. (Photo courtesy MAKEiT, Inc.)

Learning to operate MAKEiT large format 3D printers is simplified by their user-friendly features and on-board automation. The printers’ modular design ensures that critical components are easily accessible and swappable, reducing machine downtime. When needed, users can count on “real person support” from the company’s Los Angeles-based staff to help solve their printer operation challenge. Depending on the user’s preference, that support may take the form of phone assistance, video chats, or emails.

“Same day or next day factory-direct tech support is always there to answer any questions and concerns,” said Sun.

Numerous material choices

MAKEiT large format 3D printers are capable of extruding materials at temperatures up to 450°C, or 842°F. The machines work with numerous commercially available filaments, from entry level materials like PLA (polylactic acid) or PETG (polyethylene terephthalate glycol), to flexible rubber-like TPU (thermoplastic polyurethane), and even industrial grade, high temperature glass fiber nylon and PPS-CF filament (carbon fiber-reinforced polyphenylene sulfide), among others.

Depending on the project application, this versatility gives users a wide range of material choices with cost-effective prices. Sun described the MAKEiT team as “R&D oriented,” adding that they don’t hesitate to try new materials that might bring benefits to their clients.

“Based on the various materials we have test-printed, we usually create print profiles and share those with our clients, so that they have a good base to start with and don’t make the same trial mistakes as we did earlier.”

Sun also said that when adopting a filament fused fabrication 3D printing technology, a CAD designer needs to have more than a high-quality, reliable printer. They also need to consider the material’s thermal expansion and contraction because plastics expand when heated and shrink as they cool. As each layer solidifies, it may contract slightly. Different materials have different shrink rates. For example, ABS tends to shrink and warp more than PLA as it cools, she explained.

“The glass fiber nylon we use handles much higher temperature than ABS,” Sun noted. “We extrude it at 300°C, or 572°F. It has very little shrinkage and seldom warps. In addition, it is sandable with an electrical sander—no melt nor gummy. As a result, many of our automotive clients are able to 3D-print, accurately, large size plugs, molds, exterior panels, interior cores, and wheels with this amazing material.”

Useful design features

The design of the MAKEiT 2×2 3D printer makes it easy for users of the machine to watch it print a part, regardless of whether they’re in another area of the building or offsite in a remote location. It includes an on-board webcam and Raspberry Pi, which enable users to watch the action on their smartphone, tablet, or computer. “Literally, you can show what’s printing back in your office while visiting your customer’s site,” MAKEiT’s website stated.

Armando Barrios, a mechanical engineer who bought a MAKEiT 2×4+ 3D Printer, needed to 3D print a 4-foot manifold system. He went looking for a 3D printer that could handle the print volume required to print the part as one solid piece.

“From my five years of 3D printing experience, I knew multi-day prints in large formats had the potential to layer shift at any moment, which could ruin a project timeline when the piece is a nine-day print,” Barrios said in a testimonial on MAKEiT 3D’s website. “Fortunately, the 2×4 printer was designed specifically for this type of application.”

Barrios was thrilled with the printer’s use of a closed-loop system on the motors to control the print axis and eliminate layer shifting. While acknowledging that the printer “is truly in its own class,” he was most impressed with the staff at MAKEiT.

“Shelley and Salomo are always there, ready to help with anything print profile-related, and have come out to my office multiple times to help me troubleshoot issues. It is awesome to learn about the printer directly from the person who designed it. I learned a lot about how they continue to improve the product to ensure the best user experience. Salomo is a true genius in his field.”

The MAKEiT 2×2 3D printer was awarded 2nd place in the Best New Tools & Equipment category at the 2020 Specialty Equipment Market Association (SEMA) Show. It then won the Global Media Award at the 2021 SEMA Show. In addition, the MAKEiT 2×4 3D printer won the Global Media Award at the 2022 SEMA Show.