Piego Connally, assembly team leader at the Fairfax Assembly plant in Kansas City, Kansas. (Photo courtesy General Motors)

The automaker said it is leveraging advanced technology to build safer, smarter, and lower emission cars, trucks, and SUVs.

DETROIT—In June, General Motors announced plans to invest about $4 billion over the next two years in its domestic manufacturing plants to increase U.S. production of both gas and electric vehicles.

This new investment is expected to give GM the ability to assemble more than two million vehicles per year in the United States. The announcement follows the company’s recently announced plan to invest $888 million in the Tonawanda Propulsion plant near Buffalo, New York, to support GM’s next-generation V-8 engines.

General Motors plants in Michigan, Kansas, and Tennessee will expand finished vehicle production of several of GM’s most popular vehicles, the company said in a release. These facilities include Orion Assembly, in Orion Township, Michigan; Fairfax Assembly, in Kansas City, Kansas; and Spring Hill Manufacturing, in Spring Hill, Tennessee.

General Motors said it will begin production of gas-powered full-size SUVs and light duty pickup trucks at Orion in early 2027 to help meet continued strong demand. As a result, GM’s Factory ZERO in Hamtramck, Michigan, will be the dedicated assembly location for the Chevrolet Silverado EV, GMC Sierra EV, Cadillac ESCALADE IQ, and GMC Hummer EV pickup and SUV.

Fairfax Assembly will support production of the gas-powered Chevrolet Equinox beginning in mid-2027. Sales of the recently redesigned Equinox were reportedly up more than 30 percent, year-over-year, in the first quarter of 2025. Fairfax remains on track to begin building the 2027 Chevrolet Bolt EV by the end of this year. General Motors stated that it expects to make new future investments in Fairfax for its next generation of affordable EVs.

General Motors will add production of the gas-powered Chevrolet Blazer at Spring Hill starting in 2027, alongside the Cadillac LYRIQ and VISTIQ EVs, and the Cadillac XT5, the company said in the release.

“We believe the future of transportation will be driven by American innovation and manufacturing expertise,” said General Motors Chair and CEO Mary Barra, in a statement. “Today’s announcement demonstrates our ongoing commitment to build vehicles in the U.S. and to support American jobs. We’re focused on giving customers choice and offering a broad range of vehicles they love.”

General Motors has a network of 50 U.S. manufacturing plants and parts facilities in 19 states, including 11 vehicle assembly plants. Nearly one million people in the U.S. depend on GM for their livelihood, including employees, suppliers, and dealers, the company said.

“Today’s news goes well beyond the investment numbers—this is about hardworking Americans making vehicles they are proud to build and that customers are proud to own,” said GM President Mark Reuss, in the release. “As you travel the country, you can see firsthand the scale of our manufacturing footprint and the positive economic impact on our communities and our country.”

Clarios Planning to Build U.S. Manufacturing Technology and Training Center

The center will support advanced workforce training, manufacturing research and development (R&D), and technology validation.

GLENDALE, Wis.—Clarios, a manufacturer of advanced energy storage products, is planning to establish a best-in-class Manufacturing Technology & Training Center in the United States, according to a company release. The news follows a previous report by Clarios in June that it is currently evaluating U.S. locations for a next generation technology campus anchored by new supercapacitor system production.

A Clarios battery palletization robot in a packaging facility. (Photo courtesy Clarios)

The center will serve as a dedicated hub for workforce development, manufacturing research and development (R&D), and technology validation. It is intended to provide Clarios with “a world-class, secure, and high-tech environment to develop and prove next-generation manufacturing technologies before deployment across the company’s operations,” the release stated.

“Clarios is proud to take this next step in our commitment to American manufacturing,” said Clarios Chief Digital and Information Officer Chad Steighner, in a statement. “This new center will help us build both the factory and workforce of the future. By investing in cutting-edge R&D and hands-on training, we’re reshoring critical capabilities, strengthening U.S. competitiveness, enhancing safety performance, and creating opportunities for American workers.”

The new facility will be supported by $600 million earmarked for investment in state-of-the-art manufacturing—an integral part of the company’s $6 billion American energy manufacturing strategy.

This Manufacturing Technology & Training Center will advance strategic technologies such as advanced robotics, AI-augmented vision systems, autonomous material handling, and next-generation manufacturing software. These innovations are key to improving productivity, quality, and safety across Clarios’s battery production network, which supports critical mobility and energy storage applications that are vital to the U.S. economy and national security, the company said.

The facility will also serve as a national hub for upskilling Clarios’ manufacturing workforce. Programs at the center will provide hands-on training, innovation workshops, and design thinking programs to prepare all levels of workers for the future of manufacturing.

Engineers working at the center will prove out and develop turn-key solutions for application across the entire Clarios footprint, enabling more efficient, higher-quality, safer, and more skilled working environments.

Clarios is actively working to identify a location that may include public-private partnerships, incentives, and existing workforce development initiatives. The Clarios team is currently looking at states where it has a presence today. A location is expected to be announced later this year.

This announcement is said to mark a critical step in the company’s $6 billion U.S. energy manufacturing investment plan.

“This new center reflects the company’s long-term vision to lead the future of energy storage while revitalizing American manufacturing leadership—enabled by recent executive orders and using federal advanced manufacturing tax credits,” the release stated.

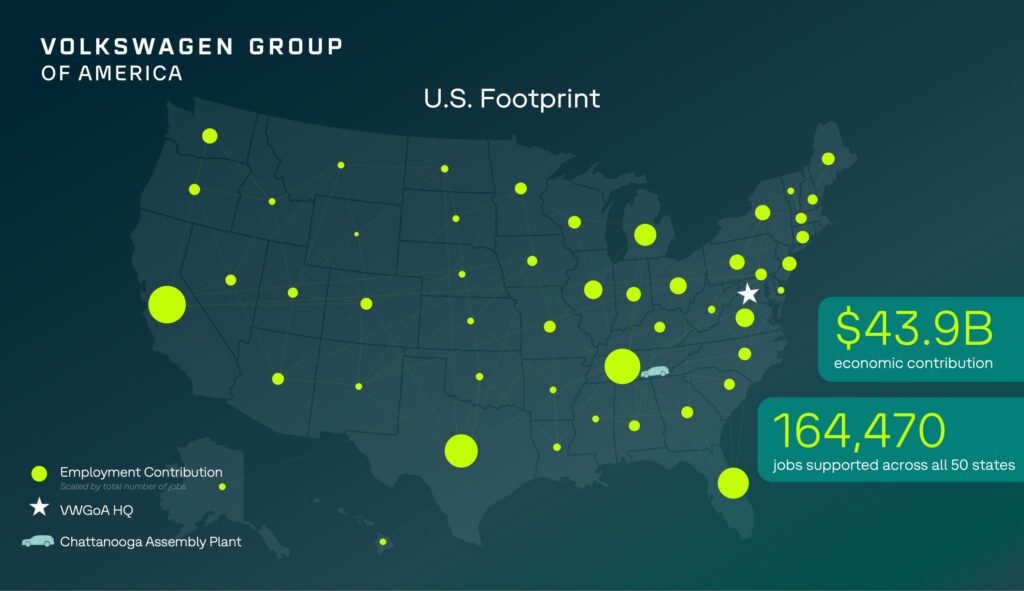

Volkswagen Group of America and its Dealers Support More Than 164,000 American Jobs, Contribute Nearly $44 Billion to U.S. Economy, Study Finds

Manufacturing jobs were found to have increased by 30 percent, while research and development jobs rose by 16 percent, since the last study in 2019.

RESTON, Va.—According to a study released by Deloitte, Volkswagen Group of America, Inc. (VWGoA) and its authorized, independent Volkswagen and Audi dealerships support more than 164,000 direct, indirect, and induced jobs across the United States while contributing nearly $44 billion in economic output.

The study, commissioned by Volkswagen Group of America, highlights the company’s recent investments and growth since the last study in 2019, VWGoA stated in a press release.

“This study underscores our deep investment and long-term commitment in the American market,” said Volkswagen Group of America President and CEO Kjell Gruner, Ph.D., in a statement. “In the past five years, we’ve grown our manufacturing footprint and advanced our R&D capabilities to drive meaningful economic impact in the communities where our valued team members live and work.”

Volkswagen Group of America and its dealers were found to support more than 164,000 American jobs and contribute nearly $44 billion to the U.S. economy, according to a study by Deloitte. About half of the direct, indirect, and induced jobs were based in six states: California, Florida, Michigan, Tennessee, Texas, and Virginia. (Image courtesy VWGoA)

The company defined direct jobs as “Volkswagen’s directly reported employees and contractors.” Indirect jobs are jobs estimated to be created by Volkswagen suppliers. Induced jobs are jobs created through household consumption associated with Volkswagen operations, according to the release. They are based on the concept that direct spending into payroll and benefits results in additional spending in the surrounding community of those workers.

About half of the direct, indirect, and induced jobs were based in six states: California, Florida, Michigan, Tennessee, Texas, and Virginia, the study found.

Since the most recent study conducted by Deloitte in 2019, VWGoA significantly expanded its U.S. footprint, strengthening its role as a major contributor to the American economy. The company’s economic contribution reportedly added more than 30,000 direct and indirect jobs and increased its total annual economic impact by more than $10 billion.

“These gains underscore VWGoA’s ongoing investment in U.S. job creation, regional supply chains, and long-term economic value,” the company said in the release.

The 2024 study also shows that VWGoA’s U.S. corporate, vehicle assembly, and research functions across the country, in addition to the operations of the more than 900 Volkswagen and Audi dealerships nationwide, generated $4.55 billion in federal, state, and local tax contributions in 2024.

The study found that in 2024, VWGoA and its dealers supported more than 48,000 direct jobs and 116,000 indirect or induced jobs in the United States. It also credited them with the following achievements:

- Increased their U.S. manufacturing workforce to nearly 4,000, an increase of more than 30 percent since 2019, driven by assembly of the ID.4, the Atlas, and the Atlas Cross Sport at its Chattanooga plant

- Accounted for $12.5 billion in payroll and benefits, contributing to a total U.S. economic output of $43.9 billion

- Delivered $6.7 billion in gross output in Tennessee, home to Volkswagen’s assembly plant, through nearly 17,000 direct, indirect, and induced jobs

- Invested $190 million into infrastructure spending through Electrify America

- Donated more than $7.5 million to charitable organizations, with an emphasis on supporting education, youth development, and environmental programs.

The Deloitte study, commissioned by VWGoA, included an analysis of employment, compensation, benefits, and supplier spending of VWGoA. The analysis was completed using IMPLAN economic modeling software and 2024 data provided by VWGoA.

Volkswagen Group of America, Inc., headquartered in Reston, is a wholly owned subsidiary of Volkswagen AG, one of the most prominent global automakers and the largest carmaker in Europe. The company houses the U.S. operations of a worldwide family of brands that include Audi, Bentley, Lamborghini, and Volkswagen. It is also the sole importer and distributer of Bugatti and Rimac vehicles in the United States.

The company also operates a state-of-the-art assembly facility in Chattanooga, Tennessee that produces Volkswagen brand vehicles such as the Atlas, Atlas Cross Sport, and ID.4. Volkswagen Group of America’s autonomous vehicle (AV) technology subsidiary, ADMT LLC, tests and proves AV technology.