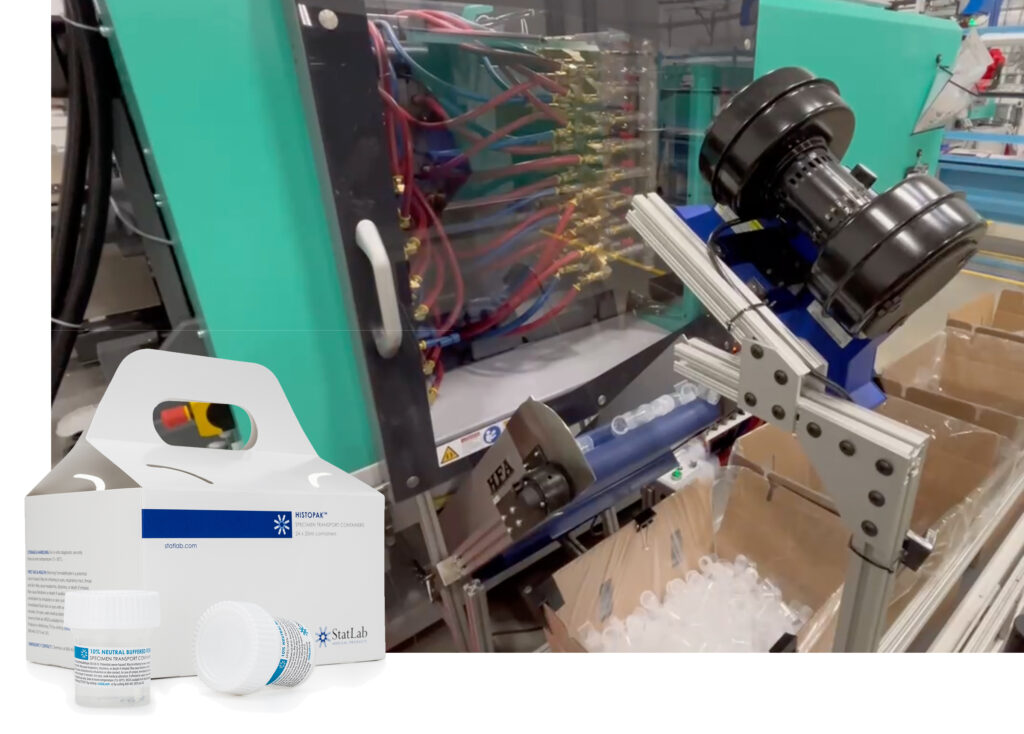

Injection molding production of 20 mL StatClick™ prefill containers at StatLab’s Arlington, Texas plant. (Photo: StatLab/Business Wire)

The company is insourcing production of injection-molded prefill containers at its Texas plant.

MCKINNEY, Texas—StatLab Medical Products, a manufacturer of essential diagnostic supplies and equipment for pathology labs, recently launched its new U.S.-based manufacturing capabilities to reinforce supply chain resilience.

The new capabilities are intended to advance StatLab’s multi-year “in-region, for-region strategy to ensure reliable, scalable production of critical reagents for pathology labs nationwide,” the company stated in a release.

The latest milestone—insourcing injection-molded prefill containers at its Arlington, Texas plant—is said to further strengthen StatLab’s position as one of the top U.S. manufacturers of formalin prefills. The company is reported to produce nearly 100 million units annually, increasing supply chain reliability for labs amid ongoing global uncertainty.

“At StatLab, it is in our DNA to invest ahead of the need,” said Sung-Dae Hong, CEO of StatLab, in a statement. “As one of the market leaders for essential pathology consumables, insourcing key containers for the products we make, including gallon bottles and prefills, empowers us to control quality and protect our customers against external market forces.”

StatLab stated in the release that it has a long history of manufacturing StatClick™ formalin prefills. However, the company added that by becoming “the first in its industry to vertically integrate container and lid production in-house,” it is “increasing control and reducing supply chain risk for this essential product used in operating rooms and labs every day across the U.S.”

In addition to bringing injection molding for prefill containers in-house, StatLab said it will begin blow molding gallon bottles during the second quarter of 2025. Production capacity for cassettes is also continuing to grow, as new injection molding cells have been added at the Arlington facility to meet strong U.S. demand, the release stated.

StatLab also announced it will currently absorb any tariff-related fees associated with products manufactured in its European facilities when selling directly to U.S. laboratories. The company described it as “another proactive move to support customers through challenging market conditions.”

Such products are reported to include PiSmart cassette and slide printers, KT microscope slides, and KT cover glass. By leveraging its U.S. and European manufacturing capabilities, StatLab said it can offer consumables for the full pathology workflow that are protected from the tariffs’ impact, empowering domestic customers to focus more on patient care.

“Delivering stability for our customers, especially in times of volatility, is part of the trust we build every day,” continued Hong. “We recognize the importance of predictable pricing and reliable access to the essential supplies labs need for accurate diagnoses.”

StatLab Medical Products offers an extensive portfolio of self-manufactured consumables and pathology equipment, developed and produced across nine manufacturing sites in the United States, United Kingdom, and Europe. The company’s global operations footprint is said to enable “an in-region, for-region” manufacturing strategy that enables it to deliver a “resilient, dependable supply chain and high-quality solutions.”

“With a customer-centric approach at our core, we bring reliability, innovation, and quality to every interaction,” the company said in the release.