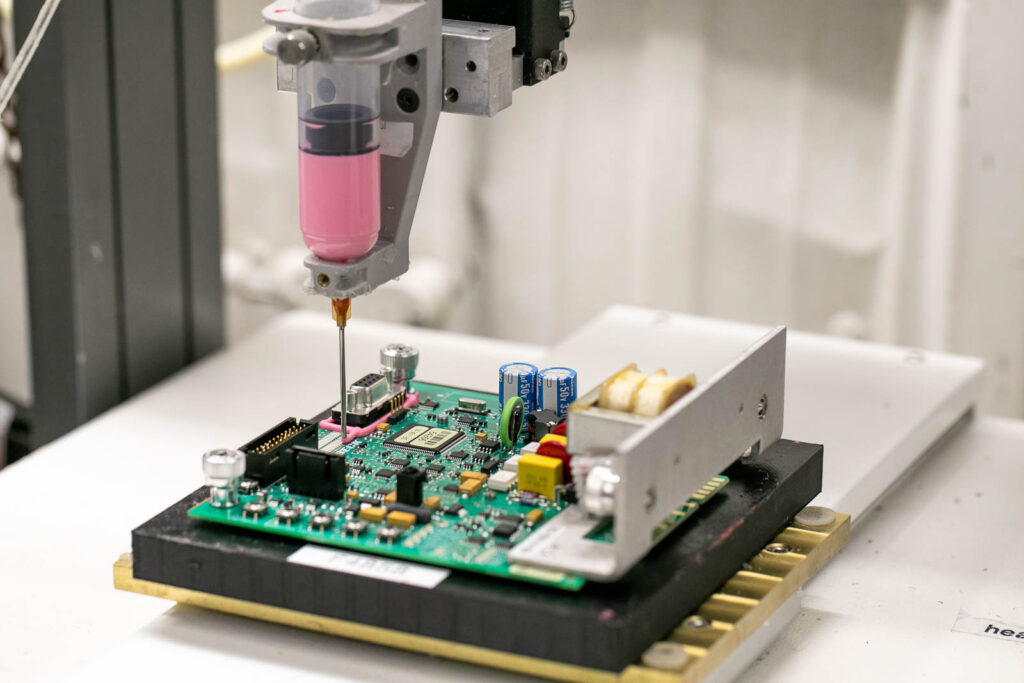

RiverSide’s engineering team created custom programming for its collaborative robot (cobot) to interface with the potting machine, so that potting could be applied precisely to specific areas of the printed circuit board in the exact amounts required. (Image courtesy RiverSide Integrated Solutions)

Riverside Integrated Solutions’ engineering team solved a complex challenge by using a collaborative robot to increase the accuracy and efficiency of a PCB potting process.

By Mark Shortt

RiverSide Integrated Solutions, Inc. (RIS), a Minnesota-based provider of electronics manufacturing services (EMS), takes pride in its ability to tailor its processes to meet customers’ unique needs and requirements.

That ability requires a degree of flexibility that RiverSide has shown in multiple ways—from scaling up to meet rising demand for customizable box builds, to creating a custom process that uses a collaborative robot (cobot) to apply potting precisely to specific areas of a printed circuit board.

“As an electronics manufacturing service (EMS) provider, we offer services rather than products,” said Rich Lieske, engineering manager at RiverSide Integrated Solutions, in an emailed response to Design-2-Part. “We offer printed circuit board assembly and product assembly—including subassembly and box build assembly—along with a wide variety of full-service solutions to take on our customers’ whole manufacturing process.”

For electronics assembly, RiverSide Integrated Solutions offers capabilities in surface mount technology (SMT), with automated rework and automated optical inspection (AOI); magazine-to-magazine handling; smart shelving floor stock inventory; X-ray reel counting; and lead-through auto-insertion. The RiverSide team uses wave solder and selective solder machines that provide no-clean and aqueous flux processes, as well as RoHS and tin/lead capabilities. They also employ robotic dispensing systems, according to the company’s website.

A Strong Focus on Ruggedized Electronics

RiverSide’s experience in electronics manufacturing extends back more than four decades. It has led to a strong focus on ruggedization techniques that enable complex electronics to operate even in the toughest, most severe environments.

“Ruggedized manufacturing is critical for a broad range of industries where circuit boards, electronics, and electromechanical parts must operate in harsh, long-term environments,” the company’s website stated. “These options help to protect the function and prevent contamination of a device and corrosion of an electronic device.”

To protect PCB components, RiverSide uses a thin polymeric-film, conformal coating material and assembly potting.

“The material works to fit the contours of a PCB precisely, protecting the components from external elements,” according to the company’s website. “In addition, with epoxy, urethane, and silicone compounds as a part of our arsenal, we can fill complete electronic assemblies to protect them from shock, vibration, moisture, and corrosion.”

Another method is low-pressure molding, which can be used to seal electronic devices and protect them against the environment. Because it employs high-performance adhesives, low-pressure molding can be used as an effective alternative to epoxy potting. RiverSide uses a MoldMan Systems™ low-pressure molding machine to encapsulate and protect electronic components from “particulates, moisture, and vibrations,” according to the website.

The company also builds and assembles what it described as “durable, customizable, enclosed circuit boards for various industries.” Its enclosed circuit boards, also called “electronic vaults,” are sealed from the environment, impermeable, and can accommodate heat sinks to dissipate heat.

“These specialty vaults shield assemblies against electromagnetic damage by blocking EMI (electromagnetic interference) activity with barriers of conductive and magnetic materials,” the website stated. “By isolating electrical devices with EMI shield enclosures, PCBs can operate in the long term, even in industrial settings with high electromagnetic frequencies.”

Personalizing a Manufacturing Process for Product Assembly

Lieske credited RiverSide’s high employee retention rates and strong in-house training program for its team’s “wealth of knowledge tailored to this specific industry.” Its engineering team works directly with each of its customers to create a personalized manufacturing process for their assemblies.

“Our engineering team has a strong focus on quality and best practices for manufacturing processes, allowing them to work directly with our customers to find solutions that work for them,” he explained. “Our engineers also help identify opportunities to maximize manufacturability, whether that means creating custom tools used in the manufacturing process, programming cobots to complete complex operations, or even helping customers recognize opportunities to improve upon their product designs.”

A RiverSide team member working on one of the company’s SMT lines. (Image courtesy RiverSide Integrated Solutions)

In addition to printed circuit boards, RiverSide’s assembly capabilities span a variety of electromechanical, mechanical, and electronic products, as well as box builds and systems integration. But although RiverSide serves various industries, it focuses mainly on agricultural and off-road equipment, test and measurement equipment, environmental controls, industrial equipment and controls, and medical and imaging equipment.

“Some of the products we assemble for our customers include agricultural machinery, farm technology, ruggedized outdoor equipment and electronics, X-ray imaging systems, and turbomachinery control systems,” said Lieske.

Among the examples of assembled products featured on the company’s website are an electromechanical enclosure for an environmental test chamber, an electro-hydraulic valve subassembly, and an electro-pneumatic assembly for a basketball training machine.

Medium Size Operation Supports Manufacturing Flexibility

According to Lieske, RiverSide’s size—“we are not a small job shop or a large conglomerate”—is an advantage because it enables its team to support customers in ways that other EMS providers cannot. The company employs approximately 300 people in three buildings, totaling approximately 200,000 square feet of manufacturing and warehousing space in Lewiston, Minnesota, and Winona, Minnesota.

“Our medium size operation allows us to be more flexible in our manufacturing and pull customers from both Fortune 100 and 500 companies,” Lieske said. “They come to us because we are able to tailor-design a manufacturing process that fits their needs perfectly and scales to meet their demand.”

Lieske said RiverSide has scaled to meet the needs of its customers by bringing on additional teams when onboarding new customers. In one example, the company was awarded new business for large, customizable box builds.

“We dedicated an entire building to their product, hired a new team, and designed a training program for individuals to become brazer-certified, as a new service we had not previously offered,” he said.

The company has also invested in technologies that enable it to streamline its processes and minimize delays. Its X-ray reel counter and Smart Shelving systems keep accurate and up-to-date counts on inventory, enabling faster switch-overs between jobs and eliminating the need for manual inventory counts, he said.

Lieske said RIS also offers its customers “full-service solutions that include supply chain management, testing, fulfillment and distribution, and even reverse logistics.” This means customers can save time and money by centralizing their manufacturing under one roof without having to invest in the space and equipment necessary to do it themselves.

“Our procurement team has personally cultivated relationships with distributors all over the world over dozens of years, allowing us to negotiate pricing, source hard-to-find parts, and ease supply chain worries,” he said.

Lieske said RiverSide Integrated Solutions has been recognized as Supplier of the Year by multiple customers in recent years. Several have awarded the company Preferred Partner or Top Supplier status, and one customer inducted RiverSide into its Hall of Fame, he said.

Cobot Plays Key Role in Custom Process for Potting PCB Assemblies

RiverSide Integrated Solutions recently identified an opportunity for increased efficiency in its potting process for one customer’s assembly. Lieske said the assembly needed potting to be applied to specific areas in precise amounts, covering and protecting some elements while leaving others uncovered.

“We were relying on hand-dispensing for a repeatable and accurate process,” he explained. “However, due to human error, along with exacerbating circumstances that limited time, like shift changes and breaks, we recognized an opportunity for increased efficiency. We decided to create a new custom process for potting these assemblies using one of our cobots.”

RiverSide’s engineering team created custom programming for its cobot to interface with the potting machine, so that potting could be applied in precise areas. An integrated optical inspection system was used for alignment and process verification.

“We can even integrate scales to confirm the exact weight of potting is distributed,” Lieske said. “And there is also a laser-based height mapping system to ensure accurate profiling to follow a programmed path, dispensing the potting material with consistent volume and pressure.”

In this way, Lieske explained, RiverSide Integrated Solutions can guarantee that exactly the same amount of potting material is applied in exactly the same places, every time.

“The cobot can do the job more precisely and faster than a human ever could, and it can run uninterrupted until the job is done. This frees up our workforce to focus on other areas of the assembly process,” he said.

Lieske added that RiverSide has had such success with this application of its cobot for complex jobs, that it has begun finding other areas where the cobot can be used in such a way.

“We’ve also purchased another cobot so that we can continue to expand the automation of such complex processes,” he said.