Strongwell’s residential home decking system is engineered for long-term performance, providing superior strength and advancing sustainability with a closed-mold manufacturing process that reduces waste and emissions. (Photo courtesy Strongwell)

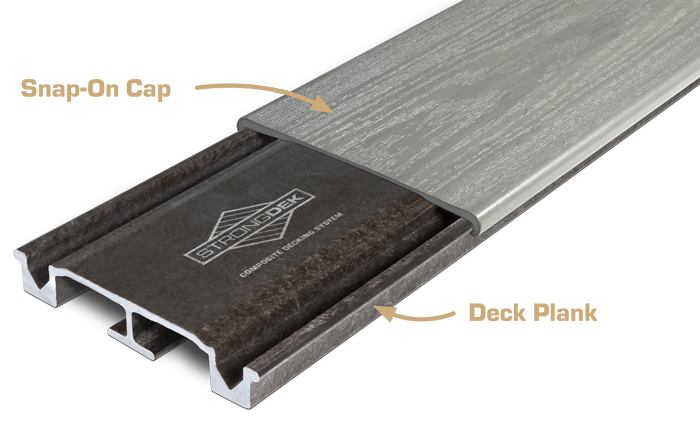

Strongwell’s two-part design combines a pultruded FRP plank with a snap-on hybrid composite top cap.

BRISTOL, Va.—Strongwell, a manufacturer of pultruded fiber-reinforced polymer (FRP) composites, was awarded the 2025 Manufacturing Innovations Award by the Southwest Virginia Alliance for Manufacturing (SVAM) for its patented STRONGDEK® structural composite decking system, the company said in a release.

STRONGDEK is reported to represent a breakthrough in decking technology by combining a pultruded FRP plank with a snap-on hybrid composite top cap. The innovative two-part design is said to deliver exceptional strength, durability, and safety, while offering easy installation and virtually no maintenance.

The product was developed to compete in the global decking market, which Strongwell described as a “multi-million-dollar” market. SRONGDEK is produced at Strongwell’s Bristol and Highlands (Abingdon, Virginia) facilities.

“STRONGDEK redefines what a composite deck can be,” said Strongwell Corporate Director of Marketing and Communications Barry Myers, in the release. “It provides superior performance, sustainability, and design flexibility, and we are proud that it is manufactured right here in Southwest Virginia. Receiving this recognition from SVAM underscores the innovation and teamwork that made this product possible.”

The STRONGDEK system features a unique replaceable cap design that allows walking surfaces to be refreshed quickly and cost-effectively without replacing the underlying structure. (Image courtesy Strongwell)

The STRONGDEK system features a unique replaceable cap design that allows walking surfaces to be refreshed quickly and cost-effectively without replacing the underlying structure. The composite decking system is engineered to exceed the strength of traditional wood and high-end composite boards, supporting wider joist spacing and higher loads while maintaining a lighter weight, the release stated.

According to Strongwell, the system is also engineered for long-term performance. It provides superior strength while advancing sustainability with a closed-mold manufacturing process that reduces waste and emissions. STRONGDEK’s service life “minimizes replacement cycles and environmental impact,” the company said in the release.

Headquartered in Bristol, Strongwell has pultrusion manufacturing facilities in Bristol and in Abingdon, Virginia; Chatfield, Minnesota; and Apodaca, Mexico. The privately held company stated that it produces structural shapes, grating, handrail, structural building panels, decking systems, composite armor, ladder rail, and numerous OEM products for its diverse customer base.